Grape-shaped microparticle aggregates, preparation method thereof, and sanitary paper

A technology of aggregates and microparticles, applied in the preparation of microspheres, botanical equipment and methods, microcapsule preparations, etc., can solve problems such as difficult mass production, inability to use water-insoluble components, and difficulty in reducing medicinal solutions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

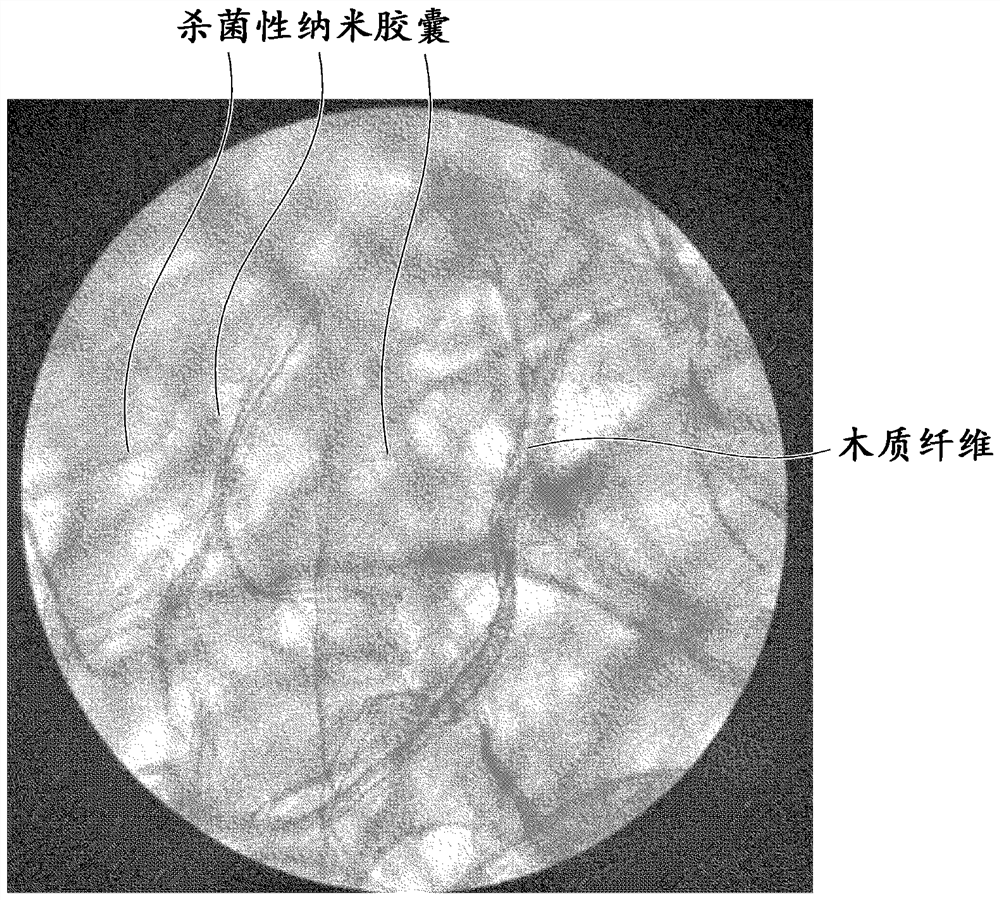

[0085] [Preparation process of bactericidal nanocapsules]

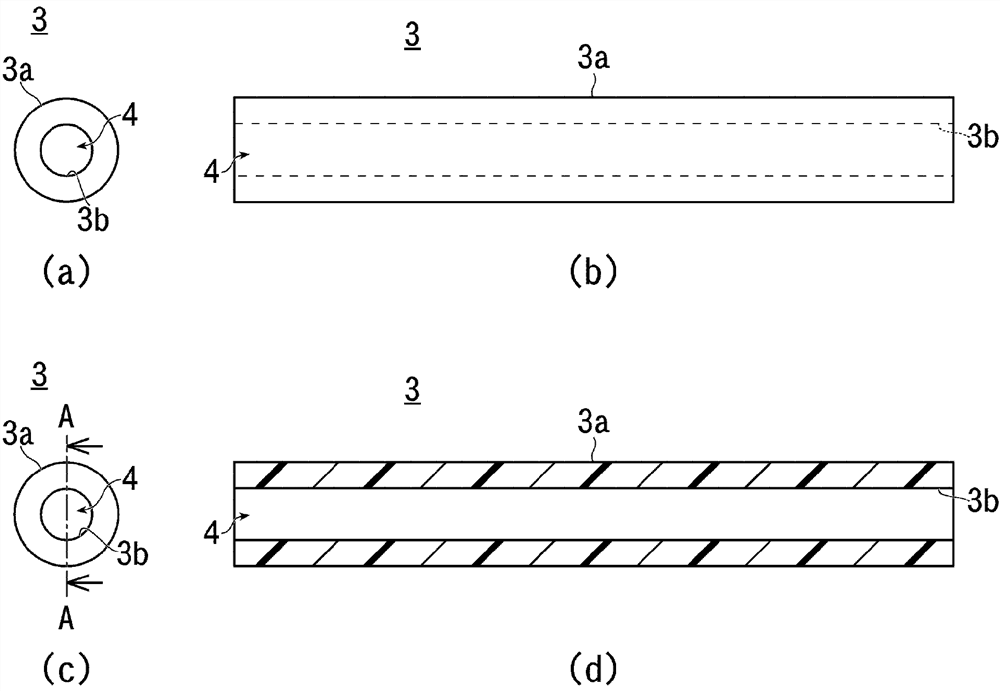

[0086] figure 2 It is a flow chart showing an example of a method for producing sanitary paper using the bactericidal nanocapsules and grape-like particle aggregates according to the present invention.

[0087] Below, refer to Figure 1 ~ Figure 4 An example of the method of the present invention will be described.

[0088]

[0089] First, prepare a quaternary ammonium salt solution ( figure 2 Process P1).

[0090] In this process, chitosan quaternary ammonium salt (2-hydroxypropyltrimethylammonium chloride chitosan) is used as the quaternary ammonium salt.

[0091] In the case of the present invention, the concentration of the chitosan quaternary ammonium salt aqueous solution is not particularly limited, but it is preferably set to 20 to 1000 ppm from the viewpoint of the cosmetic drug addition index based on each country.

[0092]

[0093] Next, make core particles 2 ( figure 2 Process P2).

[0094] I...

Embodiment

[0181] Hereinafter, the present invention is illustrated by examples, but it is not intended to limit the present invention.

[0182] In addition, unless otherwise specified, "%" described below represents "% by weight".

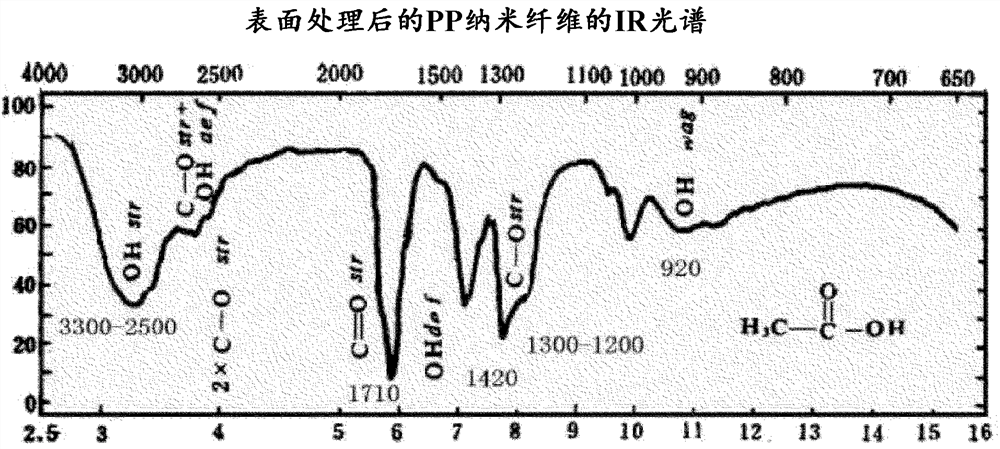

[0183] [Production of bactericidal nanocapsules]

[0184] First, an aqueous chitosan quaternary ammonium salt solution with a concentration of 1000 ppm was prepared.

[0185] 45 g of this chitosan quaternary ammonium salt aqueous solution was accommodated in the container of the above-mentioned processing device, and the container was rotated at high speed while vacuum exhausting in the container and introduction of air into the container were performed.

[0186] In this case, gradually increase the rotation speed of the container (8,000 ~ 12,000rpm), gradually increase the amount of vacuum exhaust in the container, and at the same time gradually reduce the amount of air introduced into the container, so that the air in the container The pressure is gradua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com