Method used for preparing milk sterilized at low temperature and ultrahigh pressure and capable of reducing hot processing byproducts

A technology of ultra-high pressure sterilization and by-products, which is applied in the direction of milk preservation, dairy products, applications, etc., can solve the problems of by-products of thermal processing of dairy products, reduce the nutritional value of dairy products, etc., and achieve the effect of reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Low-temperature pretreatment: After cleaning the milk, heat the raw milk at 50°C for 20 minutes, and homogenize it at 15MPa;

[0023] (2) Canning: filling the raw milk pretreated in step (1) in aseptic food-grade PET bottles;

[0024] (3) Ultra-high pressure sterilization: place the canned milk in step (2) in an ultra-high pressure device (working medium: water, working medium temperature: 3-6°C), and treat it at 500MPa for 15 minutes to reduce the Pasteurized milk that is a by-product of thermal processing.

Embodiment 2

[0026] A method for preparing low-temperature combined ultra-high pressure sterilized milk with reduced thermal processing by-products, comprising the steps of:

[0027] 1) Low-temperature pretreatment: After cleaning the raw milk, heat it at 50°C for 15 minutes, and homogenize it at 18MPa;

[0028] 2) Canning: filling the raw milk pretreated in step (1) in aseptic food-grade PET bottles;

[0029] 3) Ultra-high pressure sterilization: put the canned milk in step (2) in an ultra-high pressure device, working medium: water, working medium temperature: 5°C, and treat it at 550MPa for 12 minutes to reduce thermal processing by-products of sterilized milk.

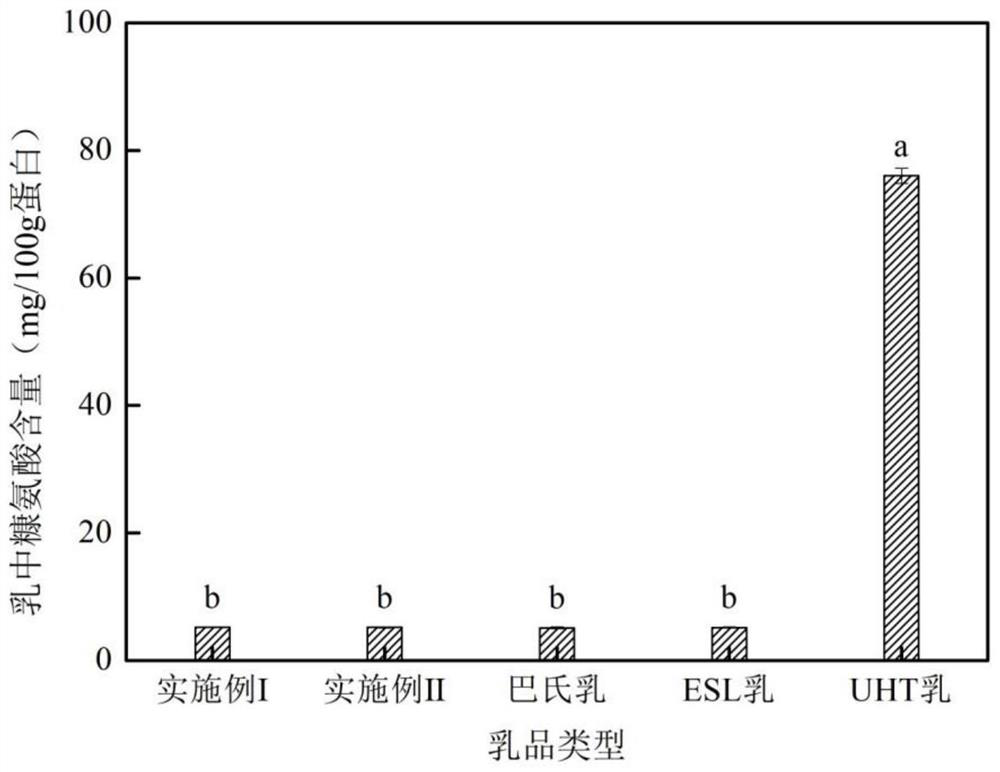

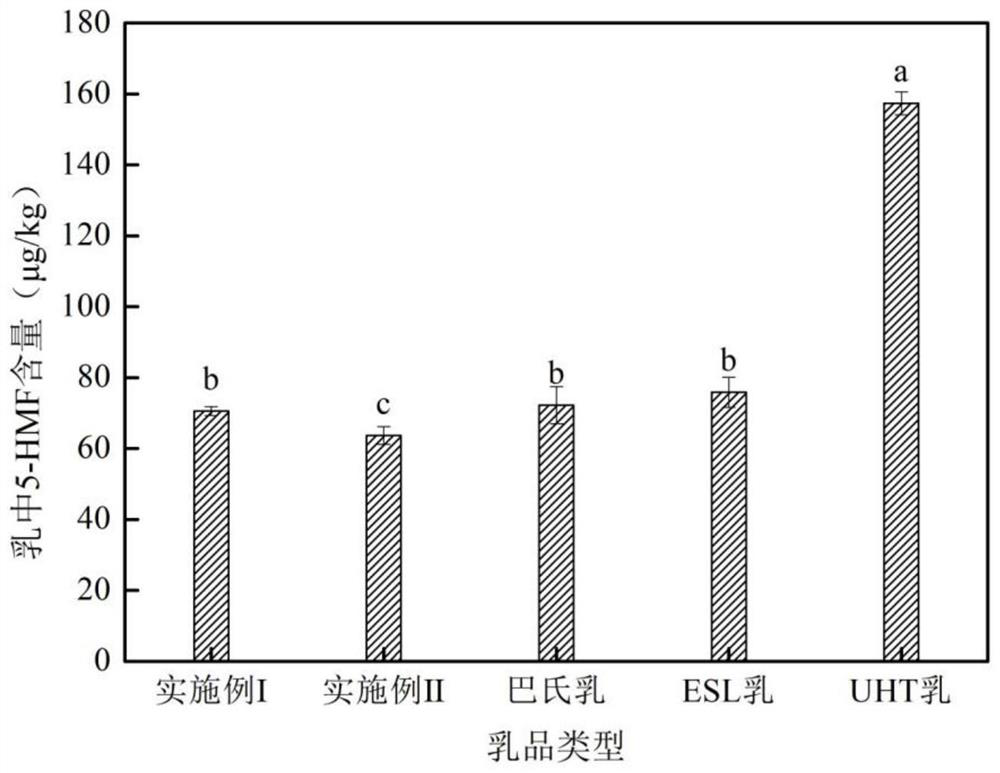

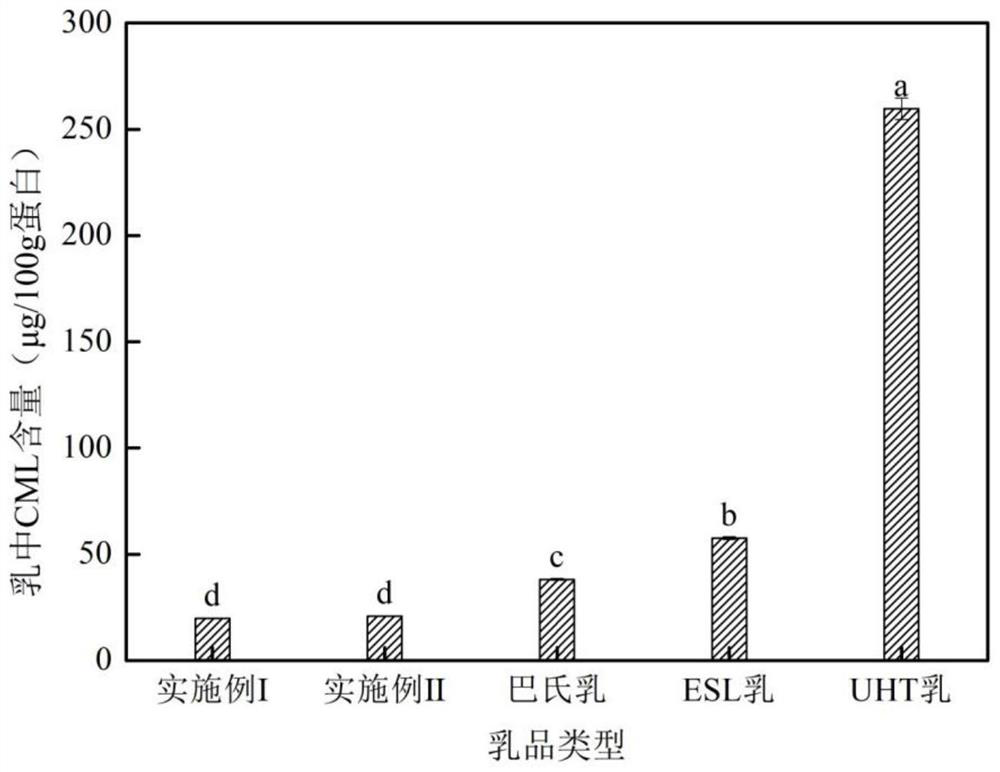

[0030] Table 1 and Figure 1-Figure 4 Compared with commercially available pasteurized milk, ESL milk and UHT milk, Example 1 and Example 2 can significantly reduce fururine, 5-hydroxymethylfurfural (5- HMF), bound carboxymethyllysine (CML) and bound carboxyethyllysine (CEL). Compared with UHT milk, liquid milk combined wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com