Cold storage and heat preservation composite cooling tank of positive pressure type oxygen respirator

A respirator and composite technology, applied in respiratory protection devices, respiratory protection containers, breathing masks, etc., can solve the problems of lack of effective thermal insulation measures for cooling devices, difficulty in adapting to quick emergency rescue, and decreasing breathing comfort. Achieve the effect of preventing the rapid loss of cold storage energy, the protection of physical energy, and the continuous constant temperature of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

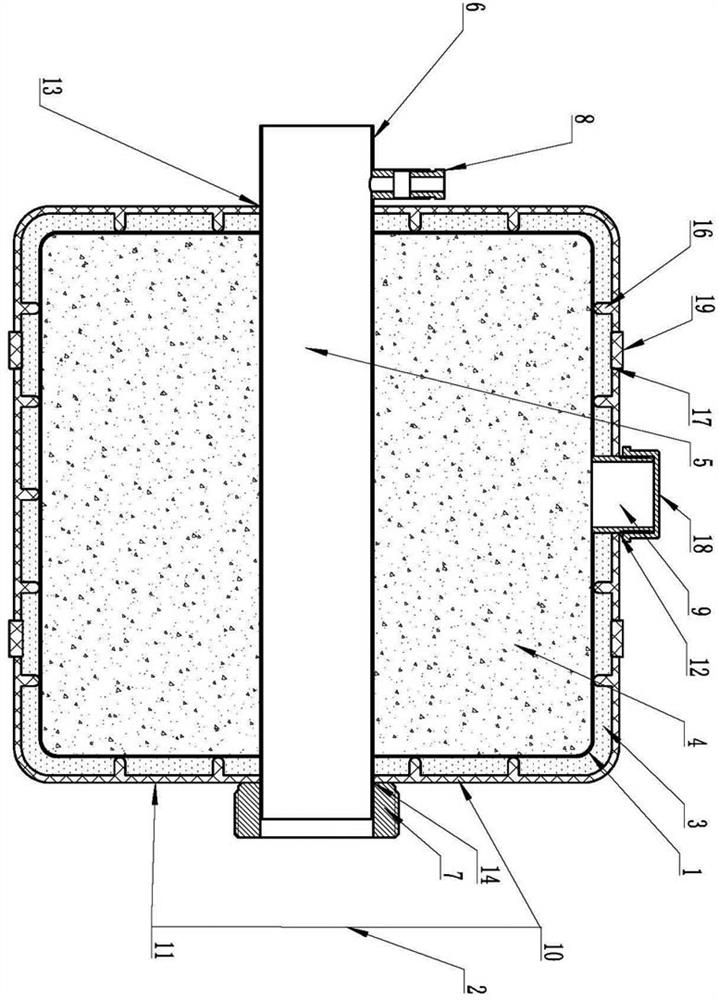

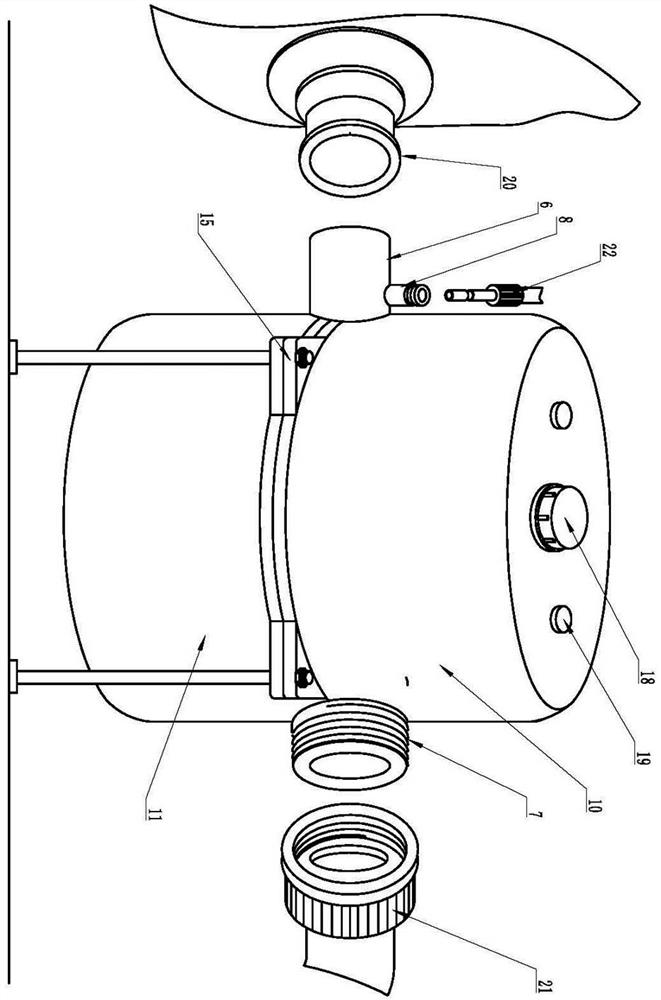

[0014] Such as figure 1 As shown, a cold storage and heat preservation composite cooling tank of a positive pressure oxygen respirator is a double tank double layer composed of a cold storage inner tank 1, a heat preservation outer tank 2, a heat insulation material 3 and a temperature control phase change cold storage agent 4 Composite cooling device.

[0015] The cold storage inner tank 1 is a barrel-shaped inner tank formed by stamping, stretching, and sealing and welding of stainless steel plates. There is a closed and embedded inner tank ventilation and cooling pipeline 5 in the tank body. Inner tank ventilating and cooling pipeline 5 two-port through-through inner tank inlet pipe joint 6 and inner tank outlet pipe joint 7 with external thread, bypass quantitative oxygen supply quick connector is vertically provided at the pipe diameter of inner tank inlet pipe j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com