Dust removal, desulfurization, denitrification and purification system and process for flue gas of lime kiln

A desulfurization, denitrification and purification system technology, applied in the field of flue gas purification, can solve problems such as insignificant effects and environmental hazards, and achieve the effects of ensuring safe operation, prolonging service life, resisting acid corrosion and long-term scouring of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

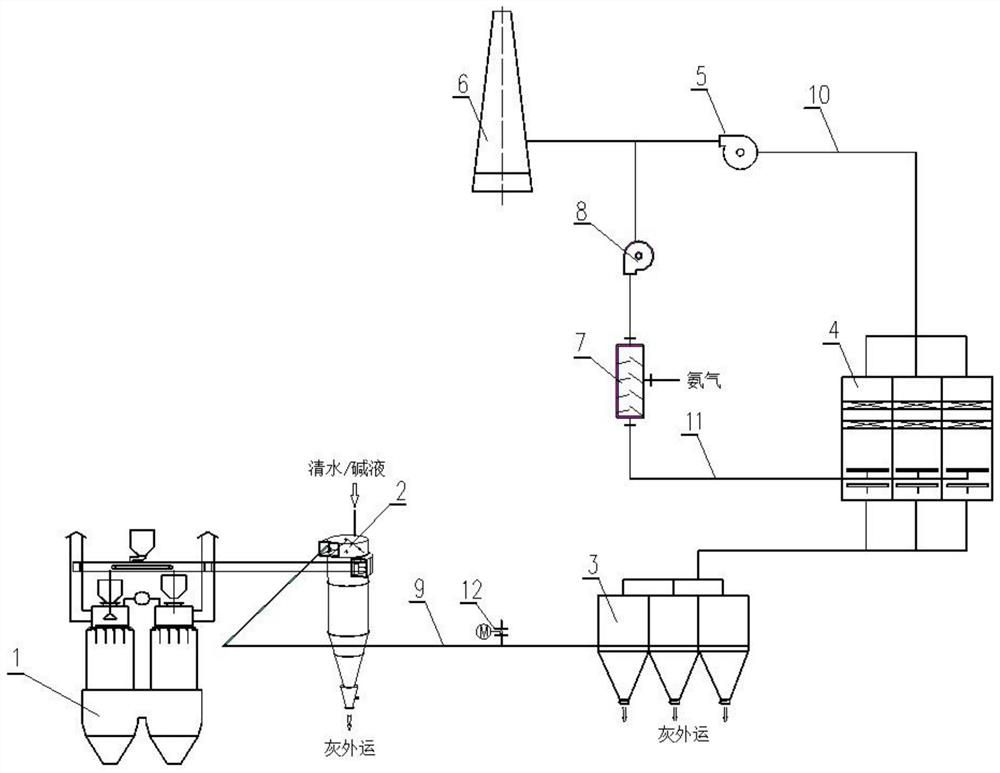

[0031] like figure 1 As shown, a lime kiln flue gas dedusting, desulfurization and denitration purification system according to the present invention includes a cyclone desulfurization tower 2, a dust collector 3, a denitration reactor 4, an induced draft fan 5, an ammonia dilution fan 8, a mixer 7 and a chimney 6 The body of the cyclone desulfurization tower 2 adopts a cyclone structure, and both sides of the upper part of the cyclone desulfurization tower 2 are respectively provided with a flue gas inlet and a flue gas outlet along the tangential direction, and the top of the cyclone desulfurization tower 2 is provided with a plurality of atomization spray guns, The bottom is provided with an ash outlet; the flue gas inlet of the cyclone desulfurization tower 2 is connected to the flue gas outlet of the lime kiln 1, and the flue gas outlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com