Robot facilitating glass cleaning

A robot and glass technology, applied in the field of mechanical processing, can solve the problems of single function, inconvenient cleaning, hand scratches, etc., to achieve the effect of avoiding glass splashing, easy cleaning, and avoiding hand scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

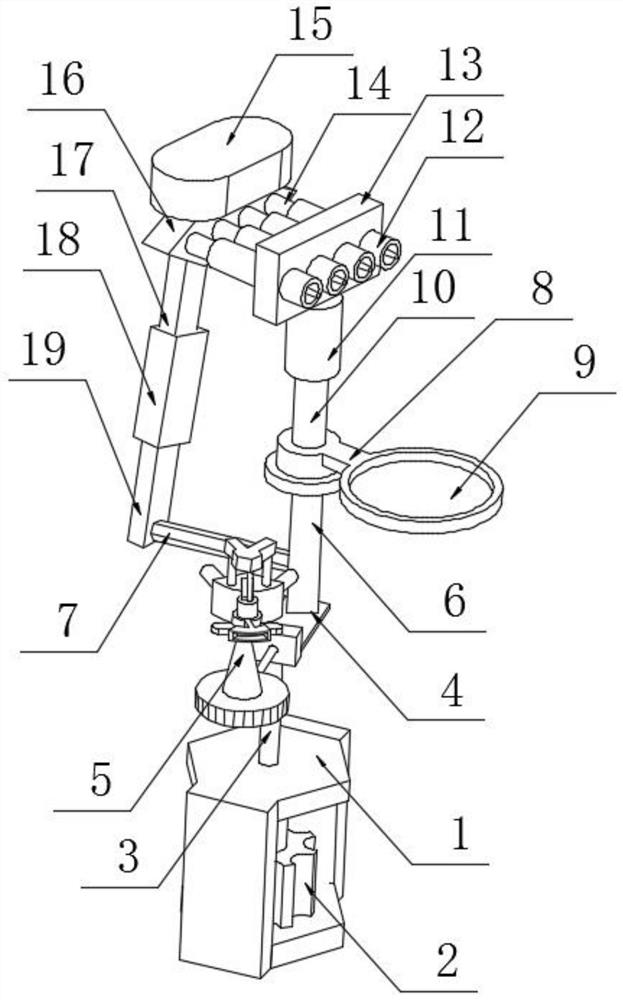

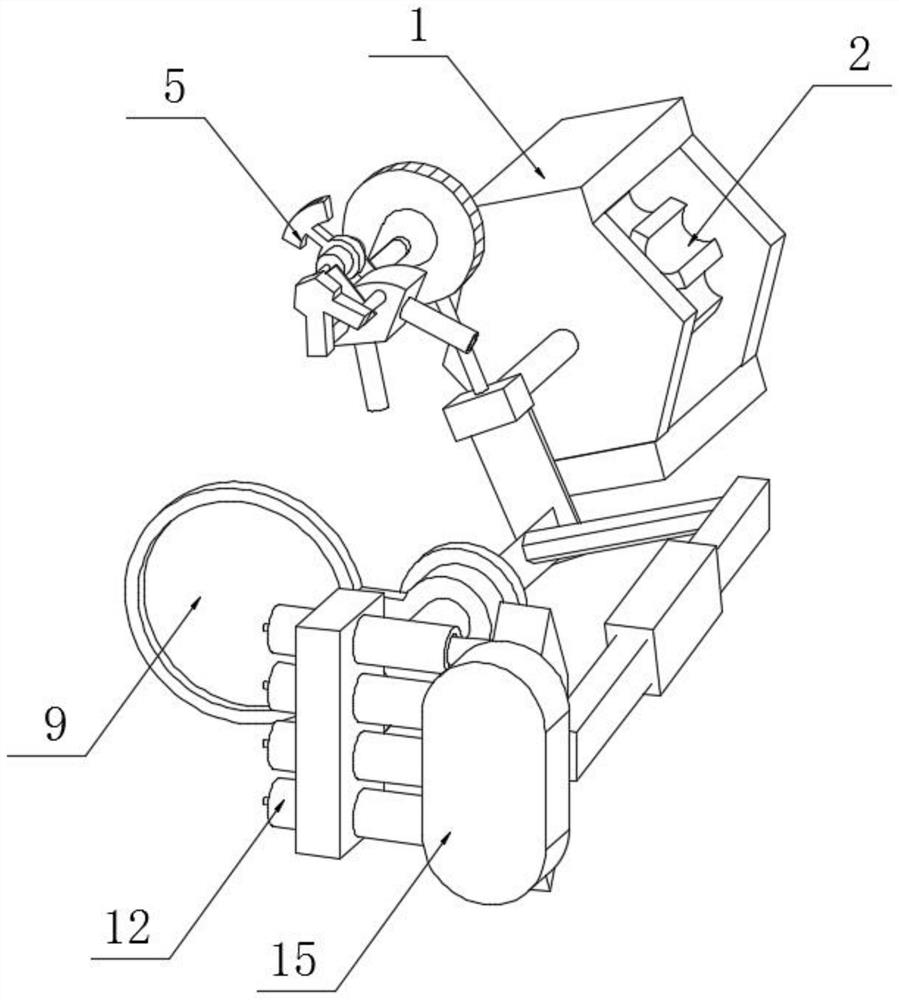

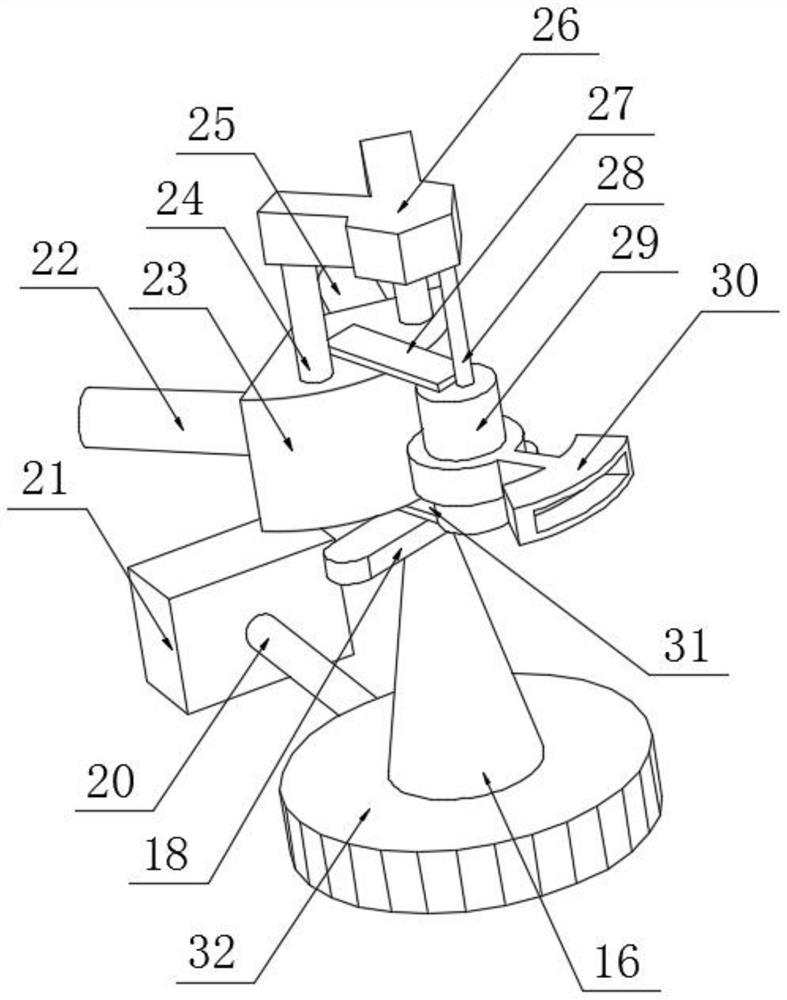

[0023] see Figure 1-4 , in the embodiment of the present invention, the robot that is convenient for glass cleaning includes a motor support frame 1 and a control box support frame 16, the inside of the motor support frame 1 is provided with a driving motor 2, and the output shaft of the driving motor 2 is socketed with the rotating shaft 3, The rotating shaft 3 can play the role of rotating. The top surface of the rotating shaft 3 is welded with a middle connecting block 21, which is mainly used for supporting and connecting. Rod 20 can play the effect of stabilizing support, and the other end that connects fixed rod 20 is welded with cleaning mechanism 5, and cleaning mechanism 5 can clean glass, and glass is cleaned effectively by cleaning mechanism 5, can directly to liquid tank 23. Add cleaning agent and water, and then carry out effective spraying through 30, such spraying effect is relatively speaking, can reach the best, can mix cleaning agent and water together, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com