Environment-friendly lead-free alloy new material alloy pipe preparation device

A lead-free alloy and preparation device technology, which is applied in metal processing equipment, grinding/polishing safety devices, manufacturing tools, etc., can solve the problem of low grinding degree of alloy tube surface, easy to scratch the skin of workers, and rough surface of alloy tube It can reduce the scratch accident, improve the grinding efficiency and reduce the surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

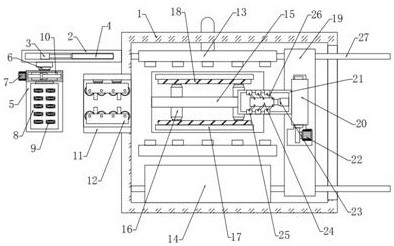

[0027] see Figure 1-5 , in an embodiment of the present invention, an environmentally friendly lead-free alloy new material alloy tube preparation device includes a housing 1, a feeding mechanism is fixedly connected to the left side of the housing 1, and a feeding mechanism is provided on the outside of the feeding mechanism for moving For the transportation mechanism of the pipe, the inside of the housing 1 is provided with a grinding tool, the outside of the grinding tool is provided with a dust suction mechanism, and the lower side of the grinding tool away from the feeding mechanism is provided with a support mechanism for driving the rotation of the pipe.

Embodiment 2

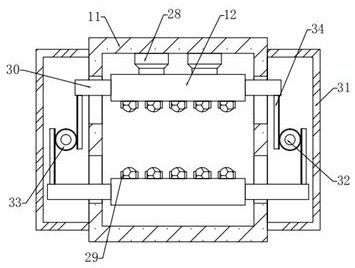

[0029] In this embodiment, the feeding mechanism includes a feeding pipe 11 fixedly connected to the left side of the housing 1, the upper and lower sides of the inner side of the feeding pipe 11 are provided with drive frames 12, and the upper and lower sides of the drive frame are 12 inside are provided with electric rollers 29, the front and rear sides of the drive frame 12 are fixedly connected with sliders 30 slidingly connected with the feed pipe 11, and the front and rear sides of the feed pipe 11 are fixedly connected with a connecting frame 31, between the sliders 30 on the upper and lower sides, there is a rotating rod 32 that is rotatably connected to the connecting frame 31, and the outer side of the rotating rod 32 is fixedly connected with a transmission gear 33, and the front and rear sides of the transmission gear 33 are meshed and connected. A rack 34 is provided, and the racks 34 on the front and rear sides are respectively fixedly connected to the sliders 30 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap