Double-lug LNG liquid tank

A liquid tank and double-ear technology, which is applied to ship parts, ship construction, ship accessories, etc., can solve the problems of small capacity and easy deformation of LNG liquid tanks, and achieve the effect of improving storage capacity, increasing strength and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

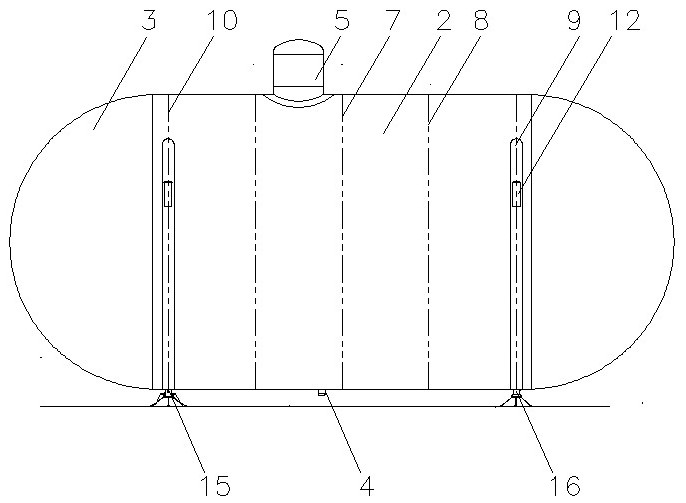

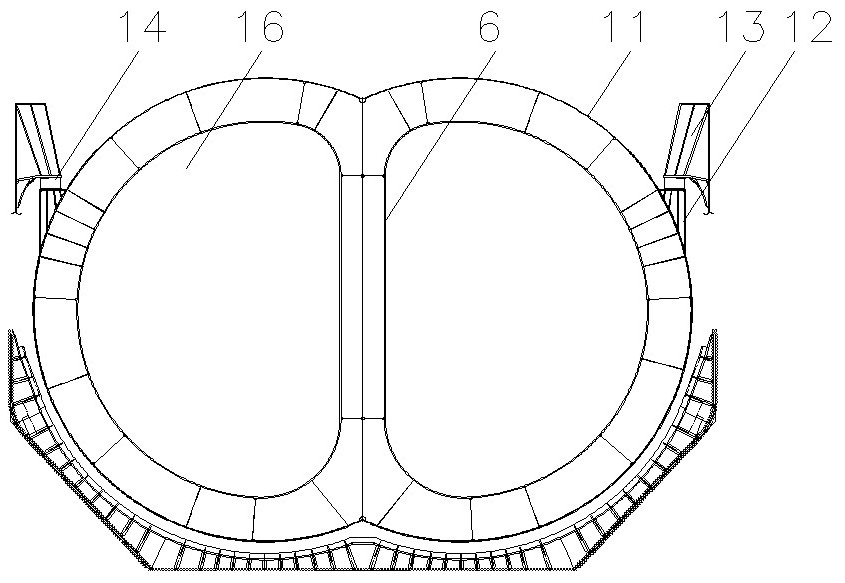

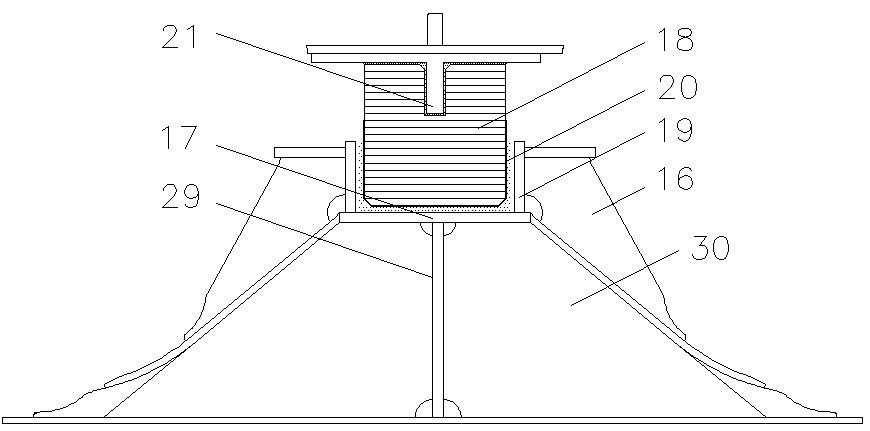

[0021] As shown in the figure, a two-ear LNG liquid tank is composed of a tank body and two saddles. The saddle is fixedly welded on the deck of the cabin, and the tank body is installed on the saddle.

[0022] The tank body is welded together by two symmetrical half-tanks 1, and the half-tank 1 is composed of the middle section 2 and the spherical head 3 at both ends of the middle section 2. The bottom of the middle section 2 is provided with a liquid collection well 4, and the middle section 2 There is an air chamber 5 on the top, and the two half-tanks 1 are separated by a mediastinal bulkhead 6 to form a closed chamber with a double-ear structure. The mediastinal bulkhead 6 can enhance the strength of the tank body in the longitudinal direction. The middle part of the middle section 2 of each half tank is welded with a swash bulkhead 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com