Continuous nitration reaction device for pendimethalin technical

A nitrification reaction device and technology of pendimethalin, applied in the direction of organic chemistry, amino compound preparation, chemical instruments and methods, etc., can solve the problems of safety hazards, production efficiency, high labor intensity, waste of raw materials, etc., and achieve low labor intensity, The effect of less equipment investment and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

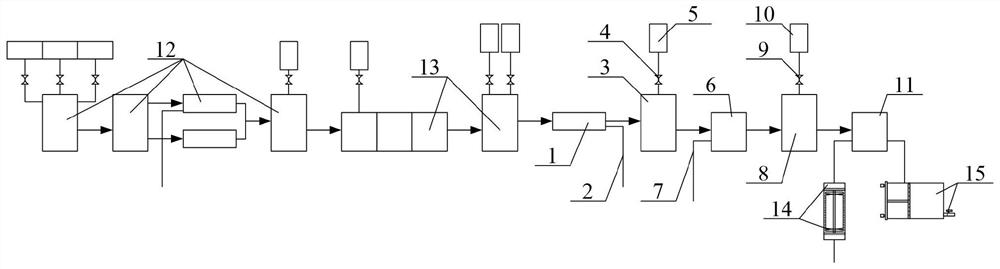

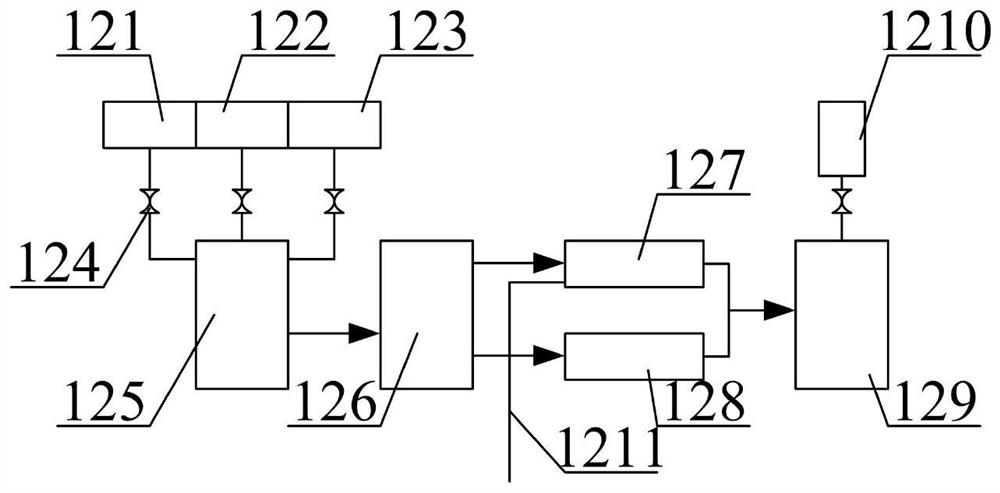

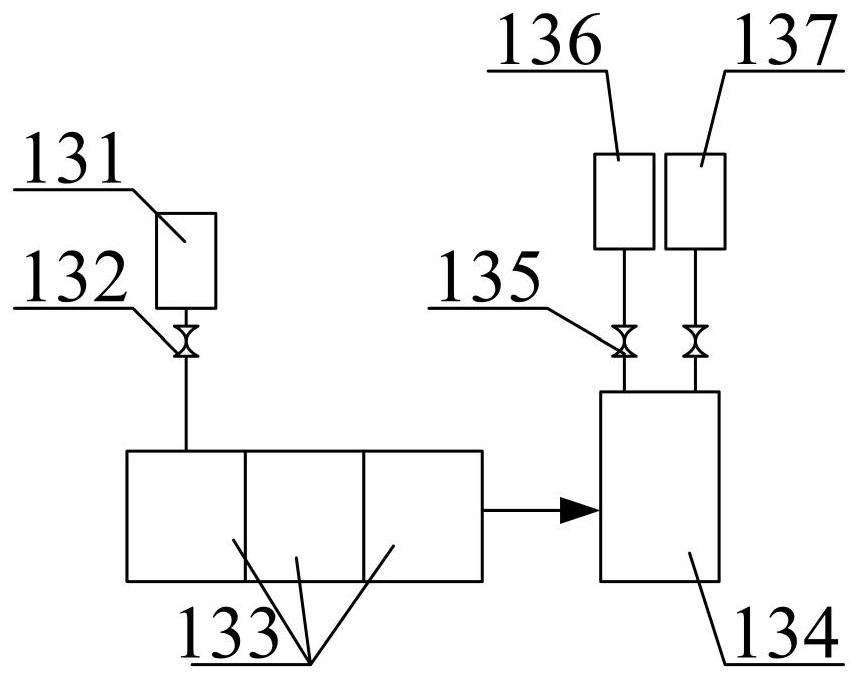

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, the pendimethalin technical continuous nitration reaction device includes hydrochloric acid separator 1, dilute nitric acid pipe 2, alkali washing tank 3, alkaline water control valve 4, alkaline water tank 5, alkaline washing separator 6, alkaline water Pipeline 7, washing tank 8, softened water control valve 9, softened water tank 10, evaporation separator 11, salt-forming extraction processor structure 12, nitrification neutralization processor structure 13, anti-sewage treatment tank structure 14 and nitrification liquid treatment and cleaning Box structure 15, the outlet of the lower right side of the hydrochloric acid separator 1 is threadedly connected with a dilute nitric acid discharge pipe 2; the outlet of the middle part of the right part of the hydrochloric acid separator 1 is connected to the left inlet of the alk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com