Sterilizing antistatic glass film and preparation method thereof

A glass film, antistatic technology, applied in the application field of polymer materials, can solve the problem of uneven quality of film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

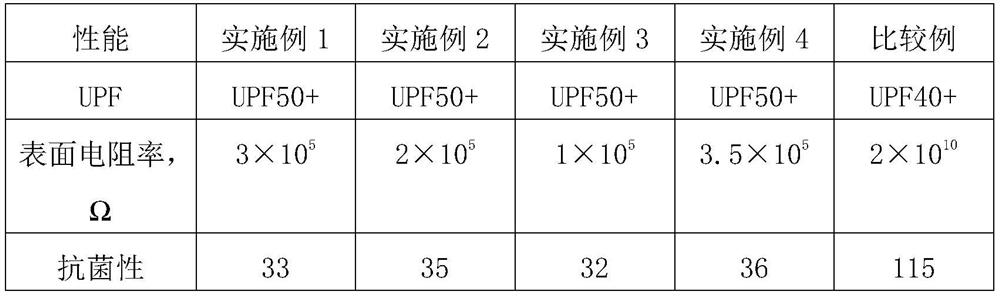

[0018] The following table 1 is the raw material ratio of the bactericidal antistatic glass film of the embodiment and the comparative example. The difference between the embodiment and the comparative example is that the comparative example removes the nano-silicon dispersant on the basis of the embodiment 4.

[0019] The adhesive is phenolic-polyvinyl acetal resin.

[0020] The composite anti-ultraviolet agent is a blend of phenyl salicylate and light stabilizer AM101, the ratio of the two is 3:1; the grade of the nano-dispersant is KYC-913, Guangzhou Yangu Trading Co., Ltd.; The nano-silver is in the form of powder with a particle size of 25-50nm; the nucleating agent is Mi11ad3988 from Milliken, USA, and the nano-silicon dispersant is a blend of nano-silicon and colloidal dispersant, model: MJ511.

[0021] Examples of the present invention and comparative examples are shown in Table 1.

[0022] Table 1

[0023] Material Example 1 Example 2 Example 3 Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com