Fireproof heat insulation felt and preparation method thereof, battery module and battery pack

A technology of battery modules and thermal insulation blankets, which is applied in the direction of battery components, secondary batteries, and isolation of batteries from their environment. Excellent flame retardancy, simple and efficient preparation method, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

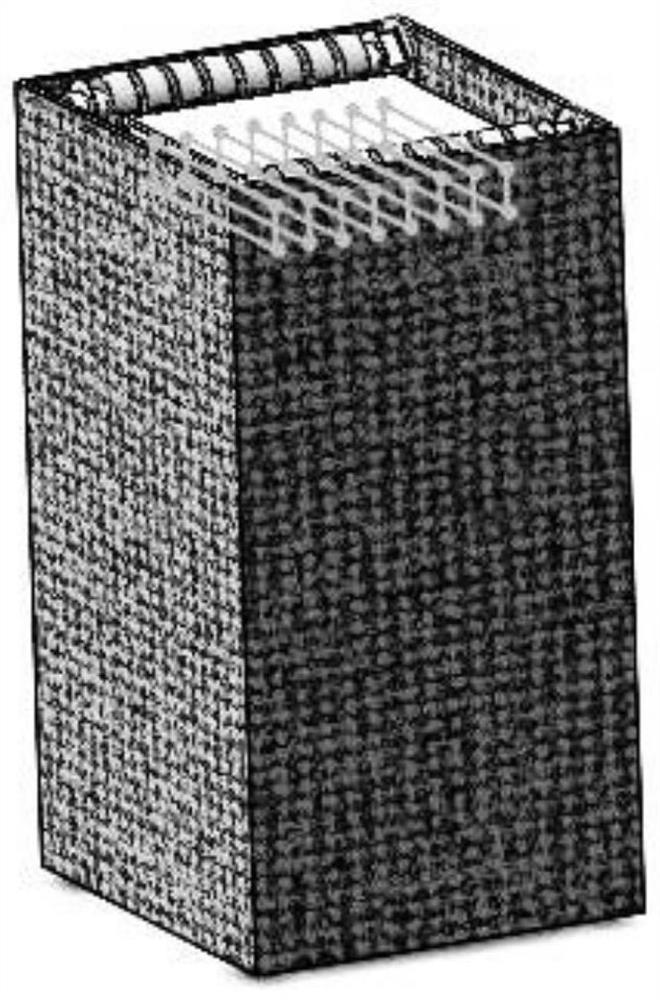

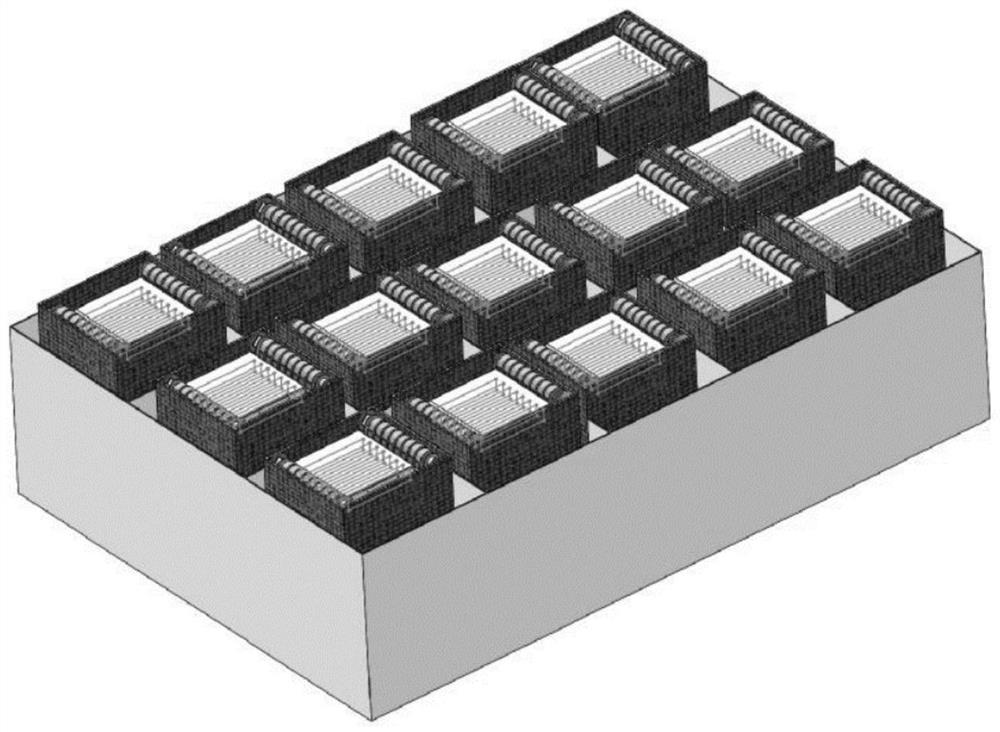

Image

Examples

preparation example Construction

[0065] According to another aspect of the present invention, the present invention also relates to the preparation method of the above-mentioned fire-proof and heat-insulating blanket, said method comprising:

[0066] a) Add airgel, hollow glass microspheres and flame retardant components to the uniformly dispersed resin dispersion, and disperse uniformly to obtain a filler dispersion;

[0067] b) Submerging the substrate fully in the filler dispersion obtained in step a), drying and calendering to obtain a fire-proof and heat-insulating blanket.

[0068] The preparation method of the fire-proof and heat-insulating blanket provided by the invention is simple and efficient, and is easy to be popularized industrially.

[0069] Preferably, the resin dispersion liquid described in step a) comprises resin and solvent;

[0070] The solvent includes at least one of ethanol, n-butanol, xylene, ethyl acetate, MEK and DMF, preferably ethanol;

[0071] Preferably, the resin dispersion ...

Embodiment approach

[0073] As a kind of embodiment of the present invention, the preparation method of fireproof insulation blanket comprises the following steps:

[0074] 1) Use a solvent to dissolve or dilute the resin, add a dispersant, and disperse evenly;

[0075] Preferably, the resin includes phenolic resin, polyurethane resin, acrylic resin, silicone rubber, etc.; the solvent includes at least one of ethanol, n-butanol, xylene, ethyl acetate, MEK and DMF;

[0076] Preferably, the resin uses thermoplastic phenolic resin powder (100 parts), and the solvent adopts ethanol (200-600 parts);

[0077] 2) Gradually add powder aerogel to the above solution to disperse evenly;

[0078] Preferably, the airgel has a particle size of 1 μm to 5 μm and a density of 0.03 g / cm 3 ~0.08g / cm 3 ;

[0079] Preferably, the airgel powder (10-100 parts) is selected from hydrophilic airgel powder;

[0080] 3) Add hollow glass microspheres to the above solution, and disperse evenly;

[0081] Preferably, the h...

Embodiment 1

[0091] A preparation method of a fireproof heat insulation felt, comprising the following steps:

[0092] 1) Dissolve thermoplastic phenolic resin powder (100 parts) with 400 parts of ethanol, add 10 parts of dispersant Disperbyk-2012, and disperse evenly;

[0093] 2) Gradually add 50 parts of silica airgel with a particle size of 1 μm to 5 μm in the above solution, and disperse evenly;

[0094] 3) Add 50 parts of hollow glass microspheres with a particle size of 5 μm to 20 μm in the above solution, and disperse evenly;

[0095] 4) Add 150 parts of decabromodiphenylethane and 40 parts of antimony trioxide) to the above solution, and disperse evenly;

[0096] 5) Soak the glass fiber needle felt in the solution of 4) and fully infiltrate it;

[0097] 6) 5) the resulting soaked felt material is dried by a coating machine;

[0098] 7) The dried felt material obtained in 6) is heated and calendered by a calender to obtain a flat fire-proof and heat-insulating felt coil with a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com