Concrete mixing station stock bin partition wall convenient to assemble and disassemble and installation method

A concrete and convenient installation technology, which is applied in the processing of walls and building materials, infrastructure engineering, etc., can solve the problems of slow installation speed, large construction waste, and large investment, so as to improve assembly efficiency, simplify construction and assembly, and reduce loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated:

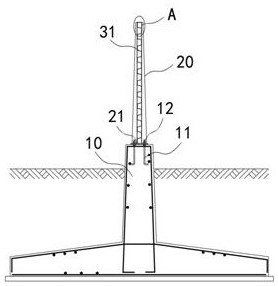

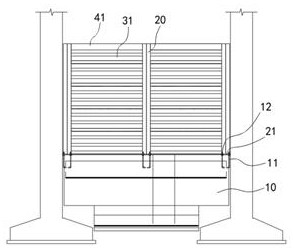

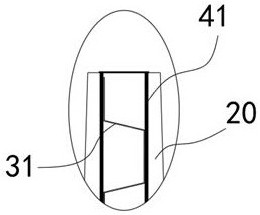

[0038] Please refer to Figure 1-3 , a convenient assembly and disassembly silo partition wall of a concrete mixing station, comprising a fixed base 10, a plurality of H-shaped steel columns 20, a plurality of fasteners 12 and a plurality of first corrugated plates 31.

[0039] Multiple groups of embedded anchor bolts 11 are embedded at the end of the fixed base 10 , and the ends of the embedded anchor bolts 11 extend out of the fixed base 10 . The bottom of the H-shaped steel column 20 is provided with a fixed base plate 21, and a set of embedded anchor bolts 11 is fixed through the fixed base plate 21. The H-shaped steel column 20 forms two guide grooves 22, and the guide grooves 22 of two adjacent H-shaped steel columns 20 are relatively formed. Limit area 23. A plurality of fasteners 12 are respectively connected to ends of the emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com