Sliding type crushing mechanism with rocker arm power

A crushing mechanism, sliding technology, applied in cutting machinery, driving device, slitting machinery, etc., can solve the problem of insufficient space for cutting motor and cable slot, low power density of rocker arm height, and inability of conveyor to transport, etc. to solve the problem of power source, save installation space and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

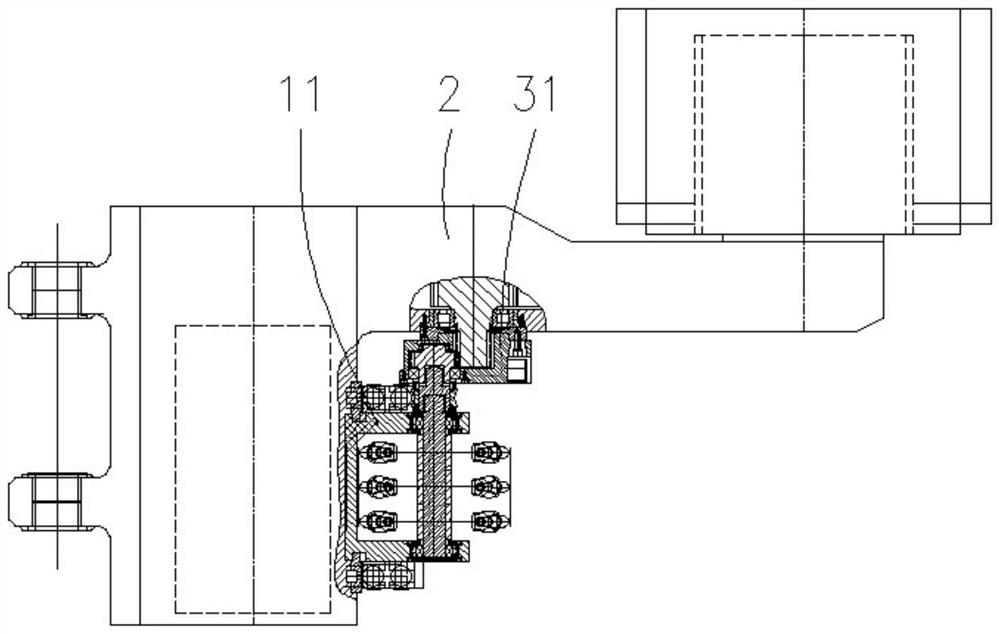

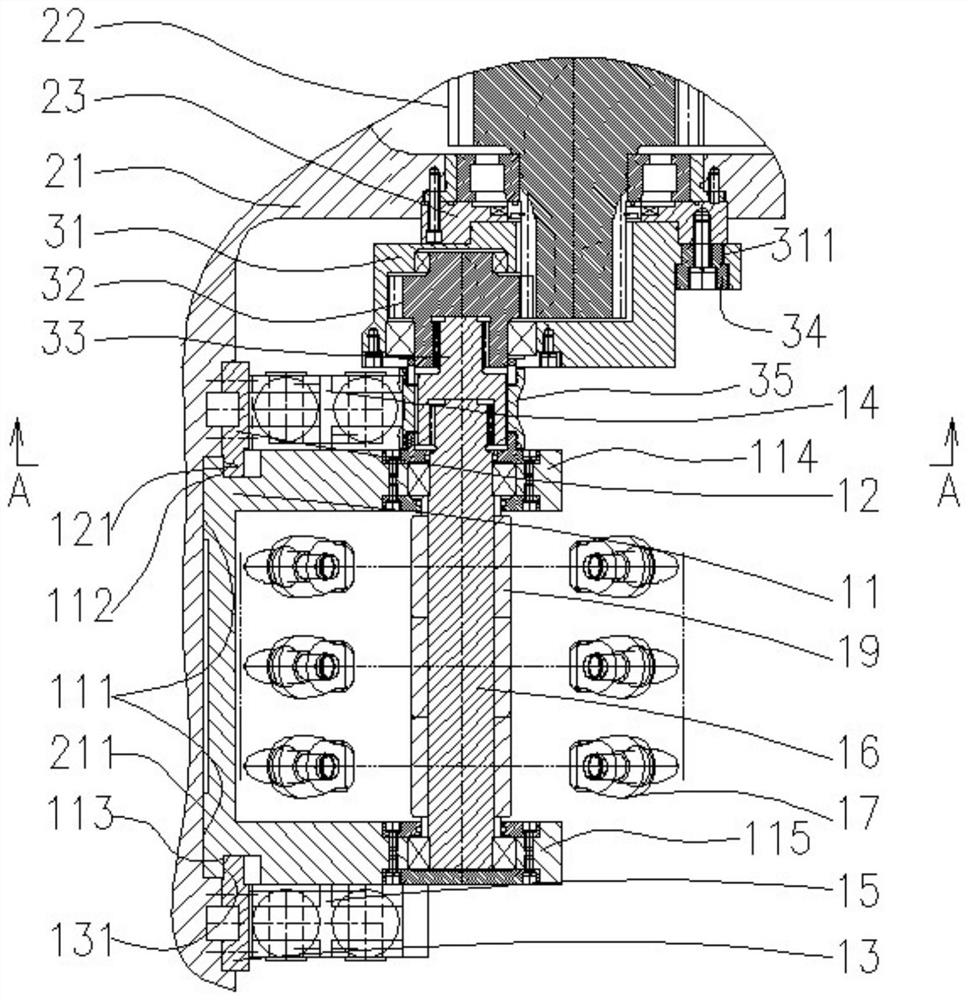

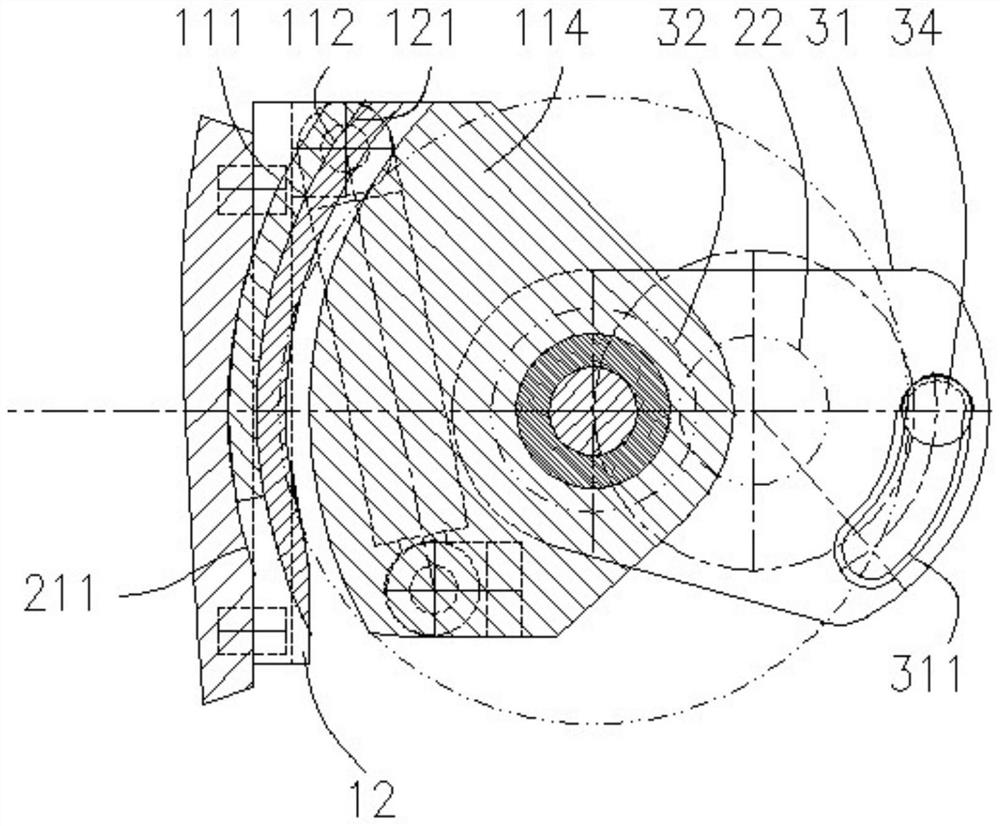

[0033] The invention discloses a sliding crushing mechanism (referred to as crushing mechanism) with rocker arm power, such as Figure 1-6 As shown, it includes a sliding seat 11, a swing housing 31, a crushing tooth assembly and a rocker arm 2 of a mining machine. A front support arm 114 and a rear support arm 115 are provided on the sliding seat. The crushing tooth assembly includes a rotating shaft 16, a plurality of sleeves 19 sleeved side by side on the rotating shaft, and crushing teeth 17 mounted on the sleeves. The front part and the rear part of the rotating shaft are rotatably supported on the front supporting arm and the rear supporting arm respectively, and the rotating shaft extends horizontally forward and backward. The swing housing is located at the rear side of the boom portion 21 of the rocker arm of the mining machine and in front of the front support arm. The rear end of a transmission gear 22 in the rocking arm of the mining machine passes through the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com