Environment-friendly low-noise chain bucket machine traction system

A traction system, chain bucket machine technology, applied in mining equipment, mining equipment, earthwork drilling and other directions, can solve the problems of low transmission efficiency, large friction noise, etc., achieve high transmission efficiency, solve noise, reduce impact and friction noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

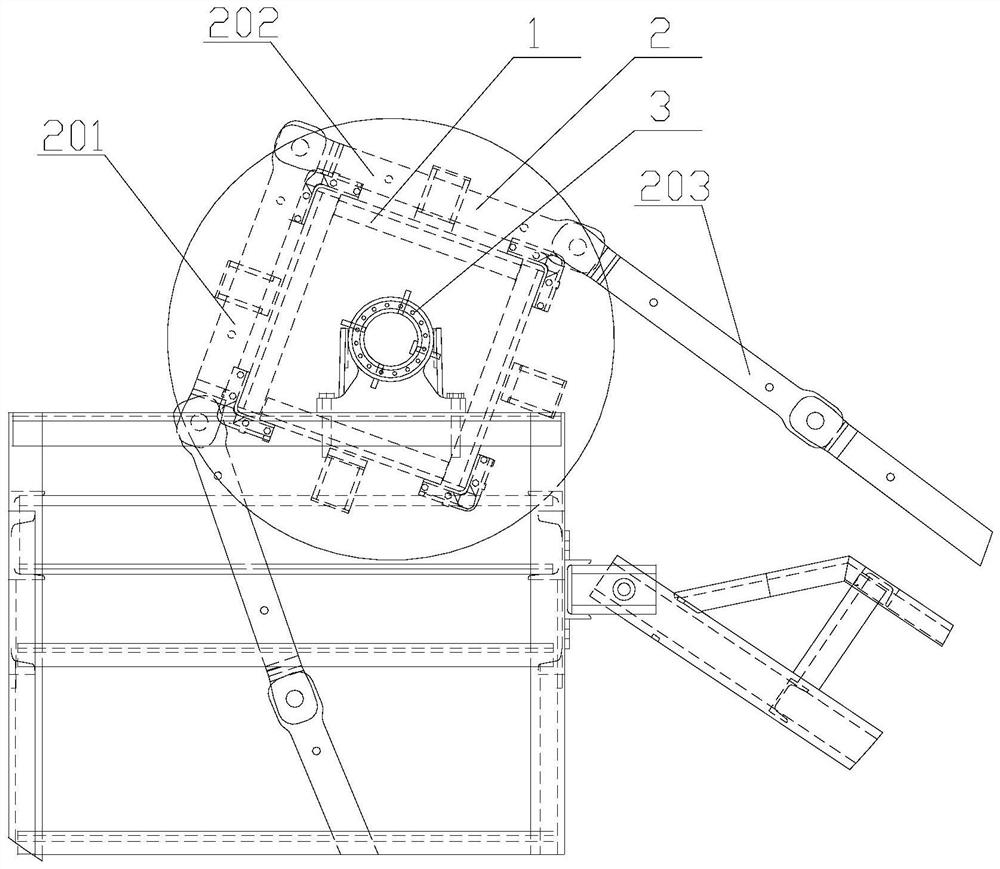

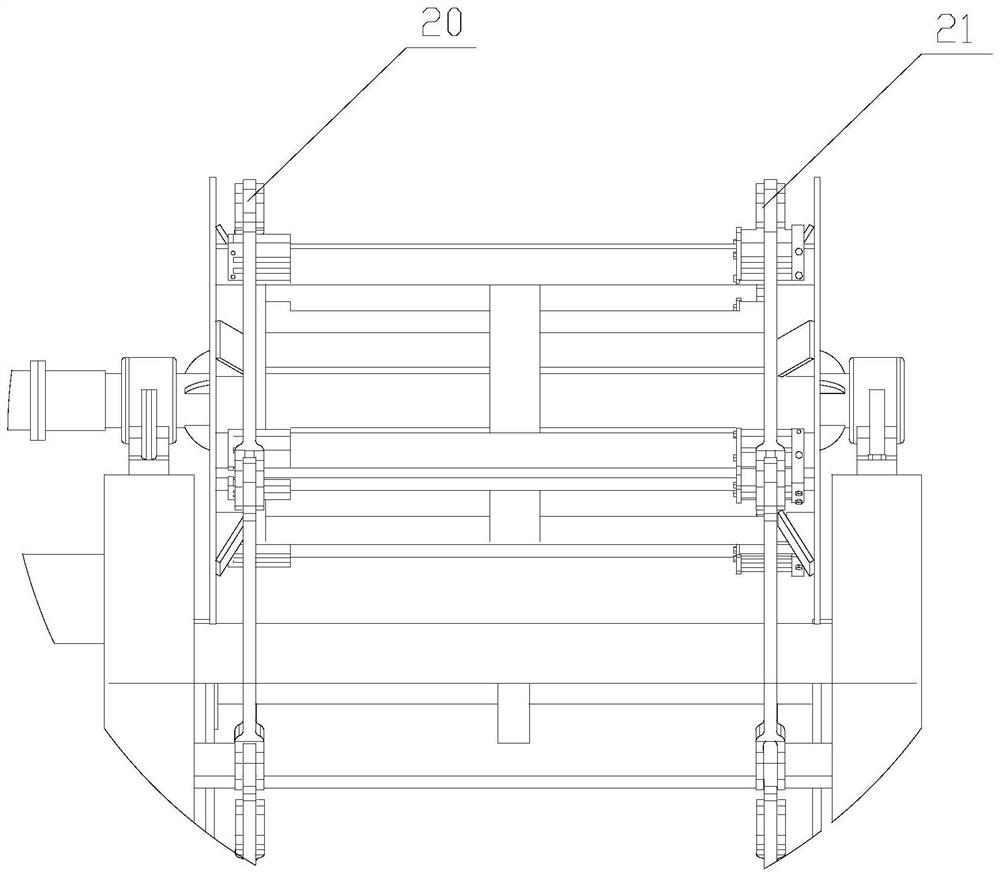

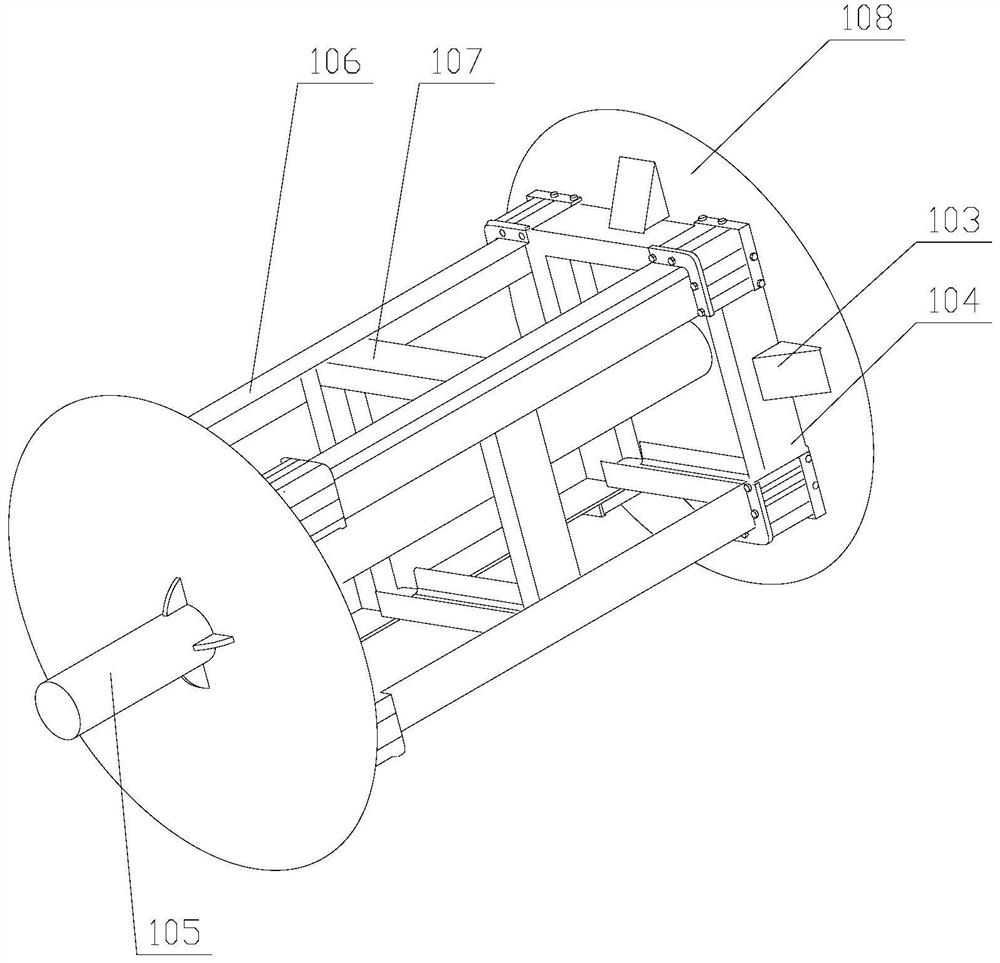

[0030] like Figure 1~6 As shown, the embodiment of the present invention provides an environmentally friendly and low-noise chain bucket machine traction system, including a square wheel 1 and a chain plate group;

[0031] The four-corner wheels 1 are arranged in pairs, respectively located at the upper end and the lower end of the traction system. The four-corner wheels 1 are divided into driving wheels and steering wheels according to functions. The four-corner wheels 1 on the upper end are driving wheels and play a driving role. It is a steering wheel and plays a steering role. Square wheel 1 is as driving and steering member, and the driving wheel that is positioned at the upper end makes rotary motion when external power input, drives traction mechanism to work, and the cross-section of driving wheel and steering wheel all is identical frame type equilateral quadrilateral structure (due to driving wheel The structure is the same as the steering wheel, so the present emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com