Interlocking protection method for high-pressure steam pipe network

A high-pressure steam, interlocking protection technology, applied in the components of steam boilers, steam boilers, combustion methods, etc., can solve problems such as complex systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific implementation manners described here are only used to illustrate and explain the embodiments of the present invention, and are not intended to limit the embodiments of the present invention.

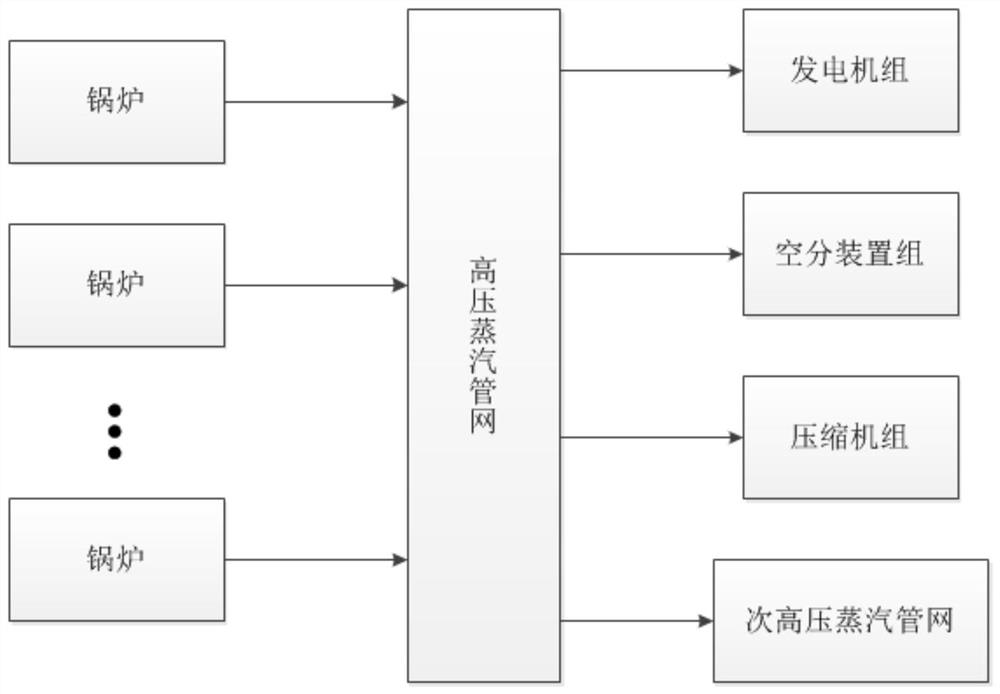

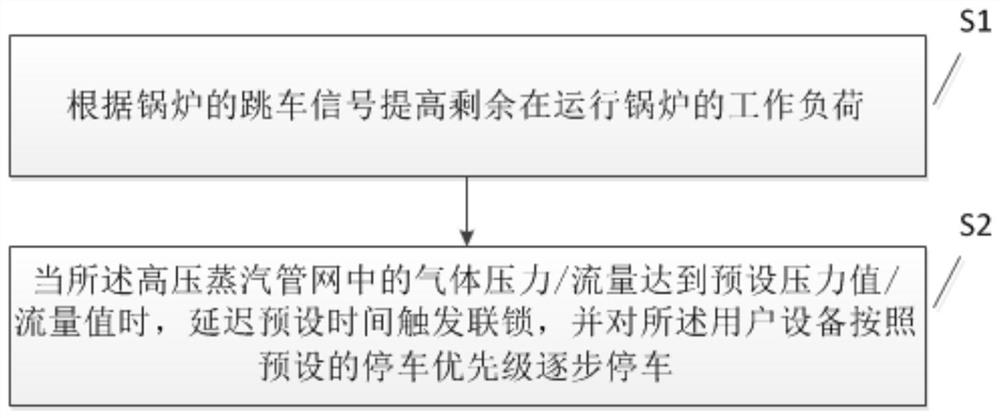

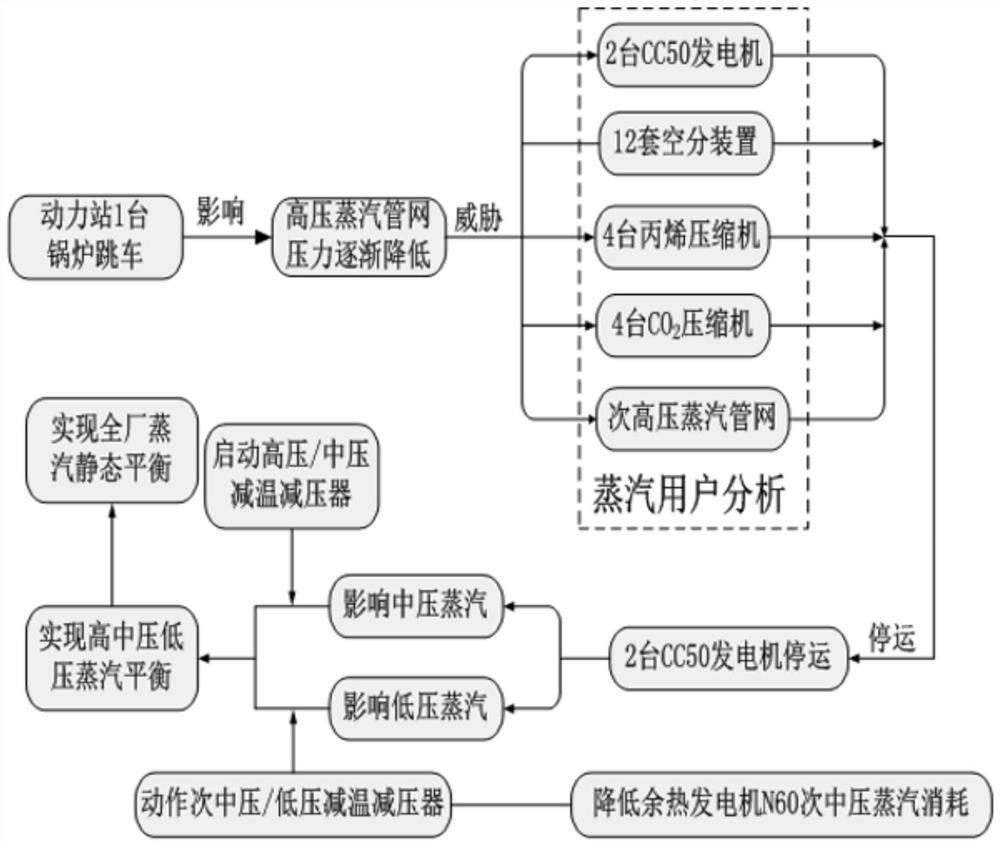

[0028] In the event of a boiler failure in a large-scale coal chemical industry system, the interlock protection system is used to adjust the process conditions of the high-pressure steam pipe network between the boiler equipment and the user equipment, and the boiler and the high-pressure steam are automatically allocated through automatic allocation of the amount of high-pressure steam. The high-pressure steam balance of the user unit prevents the interruption of the high-pressure steam caused by the unplanned shutdown of the boiler, resulting in a large load reduction or large-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com