Temperature/humidity field collaborative multi-heat-exchanger heat pump drying system and control method thereof

A technology of heat pump drying and field coordination, which is applied in drying, heat pumps, dryers, etc., to achieve the effects of maintaining heat balance, improving dehumidification energy efficiency, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

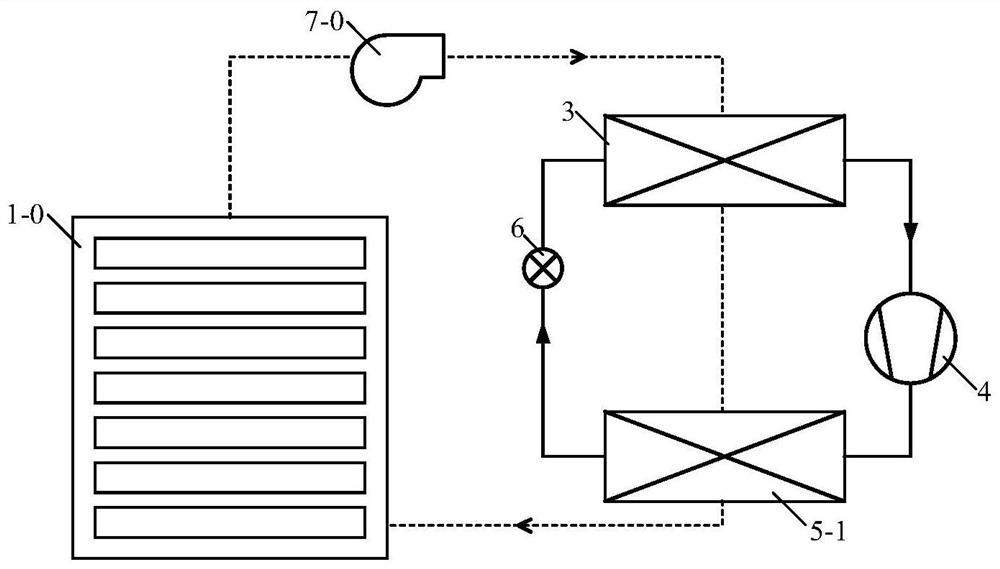

[0068] The temperature / humidity field coordinated multi-heat exchanger heat pump drying system in this embodiment (see figure 2 ), including refrigerant cycle and air cycle.

[0069] The refrigerant cycle includes the refrigerant channel of the evaporator 3, the compressor 4, the refrigerant channel of the first condenser 5-1, the refrigerant channel of the second condenser 5-2, the refrigerant channel of the subcooler 5-3, which are connected in sequence. Refrigerant channel and throttling element 6, the throttling element 6 is connected with the refrigerant channel of the evaporator 3 to form a cycle;

[0070] The air circulation includes the first return air passage and the second return air passage in parallel; the first air return passage of the air circulation includes the sequential connection of the drying room 1-0, the circulation fan 7-0, and the pre-cooling water coil 2-0. Air passage, the air passage of evaporator 3, the air passage of subcooler 5-3, the first bl...

Embodiment 2

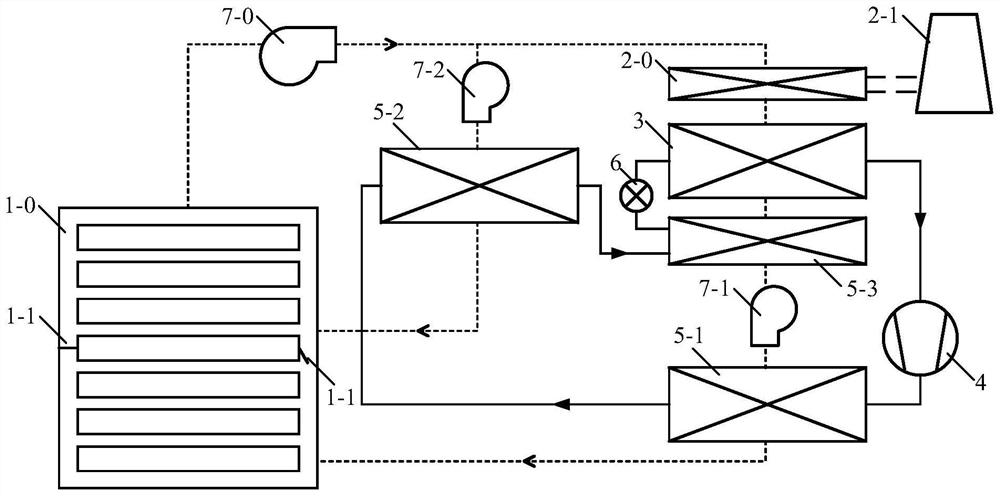

[0080] The basic system principle in this embodiment is consistent with that of Embodiment 1, and a variety of similar air supply modes in the drying room (air supply after external mixing, internal mixing of segmented air supply, and external mixing of segmented air supply) can also be realized.

[0081] see Figure 5 , the main difference of this embodiment is that the multiple heat exchangers adopt different arrangements and connection forms to achieve air supply states with different temperatures and humidity, and to meet the needs of material drying. In this embodiment, the first condenser 5-1 and the second condenser 5-2 in the refrigerant cycle are connected in parallel to heat the return air in the first and second return air passages to a similar temperature, and the first condenser 5 -1. The refrigerant at the outlet of the second condenser 5-2 is mixed by the confluence valve 9, then flows through the cooler 5-3 for subcooling, and then returns to the air at low tem...

Embodiment 3

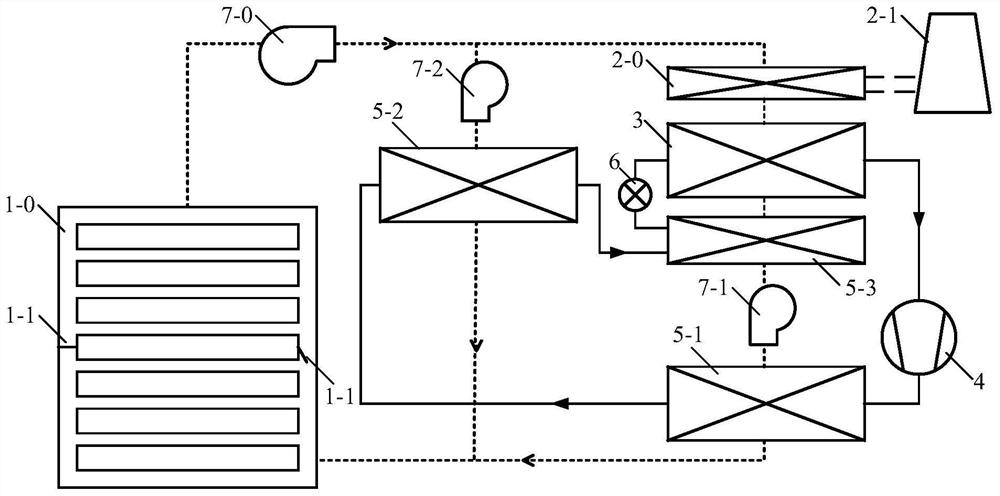

[0083] The basic system principle in this embodiment is consistent with that of Embodiment 1, and a variety of similar air supply modes in the drying room (air supply after external mixing, internal mixing of segmented air supply, and external mixing of segmented air supply) can also be realized.

[0084] see Figure 6 , the main difference of this embodiment is that the multiple heat exchangers adopt different arrangements and connection forms to achieve air supply states with different temperatures and humidity, and to meet the needs of material drying. In this embodiment, the series sequence of the first condenser 5-1 and the second condenser 5-2 is changed in the refrigerant cycle, and the refrigerant discharged from the compressor 4 first flows through the second condenser 5-2, and the superheated The steam cools down and condenses to release heat, heats the return air in the second return air passage to the highest temperature, then flows through the first condenser 5-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com