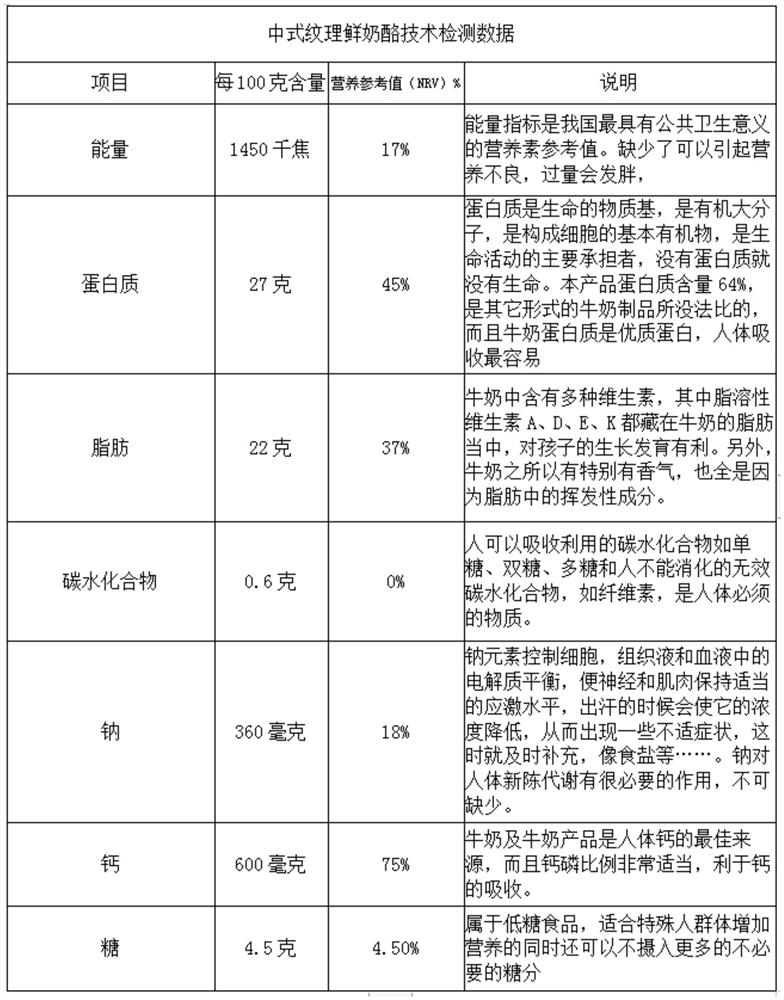

Chinese style texture hand-torn fresh cheese and processing technology thereof

A fresh cheese and texture technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of cow dung smell, fresh cheese without Chinese texture and its products, and cowshed smell, etc., to achieve good source and large market promotion Value, nutritious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] It consists of the following raw materials by weight: 100-200 parts of raw milk, 100-200 parts of compound rennet, 10-20 parts of salt, 10-20 parts of sugar, 10-20 parts of aniseed, 10-20 parts of pepper, pepper 10-20 parts, 10-20 parts of cumin, 10-20 parts of cumin, 10-20 parts of green onion, 10-20 parts of ginger, 10-20 parts of garlic, 10-20 parts of Shiquan powder, 6-10 parts of monosodium glutamate , 6-10 parts of curry powder, 6-10 parts of fermented bean curd, 1-2 parts of dried strawberries, 1-2 parts of dried blueberries, and 1-2 parts of dried cranberries.

[0017] Further, the raw milk is put into use after passing the acceptance test, and the compound rennet is a liquid, powder and For the tablet enzyme preparation, the natural seasoning and the processed seasoning are not fixed, and other edible seasonings are applicable to the present invention.

[0018] Further, the processing technology of a Chinese-style texture shredded fresh cheese includes the fol...

Embodiment 2

[0022] Further, it consists of the following raw materials by weight: 120 parts of raw milk, 120 parts of compound rennet, 12 parts of salt, 12 parts of sugar, 12 parts of aniseed, 12 parts of Chinese prickly ash, 12 parts of pepper, 12 parts of cumin, 12 parts natural, 12 parts green onion, 12 parts ginger, 12 parts garlic, 12 parts Shiquan powder, 6 parts monosodium glutamate, 6 parts curry powder, 6 parts fermented bean curd, 1 part dried strawberry, 1 part dried blueberry, 1 part dried cranberry Parts, other raw material composition and technological process steps are identical with embodiment 1.

Embodiment 3

[0024] Further, it consists of the following raw materials by weight: 140 parts of raw milk, 140 parts of compound rennet, 14 parts of salt, 14 parts of sugar, 14 parts of aniseed, 14 parts of Chinese prickly ash, 14 parts of pepper, 14 parts of cumin, 14 parts natural, 14 parts green onion, 14 parts ginger, 14 parts garlic, 14 parts Shiquan powder, 7 parts monosodium glutamate, 7 parts curry powder, 7 parts fermented bean curd, 1 part dried strawberry, 1 part dried blueberry, 1 part dried cranberry Parts, other raw material composition and technological process steps are identical with embodiment 1.

[0025] Example 3:

[0026]Further, it is composed of the following raw materials by weight: 160 parts of raw milk, 160 parts of compound rennet, 16 parts of salt, 16 parts of sugar, 16 parts of aniseed, 16 parts of Chinese prickly ash, 16 parts of pepper, 16 parts of cumin, fennel 16 parts natural, 16 parts green onion, 16 parts ginger, 16 parts garlic, 16 parts Shiquan powder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com