Sewage treatment plant laminar flow type sedimentation tank sludge scraping and sucking device and method

A sewage treatment plant, advection-type technology, applied to the feeding/discharging device, separation method, sedimentation separation, etc. of the settling tank, can solve the problem of wasting electric energy, reduce operating frequency, improve mud scraping efficiency, and reduce energy wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

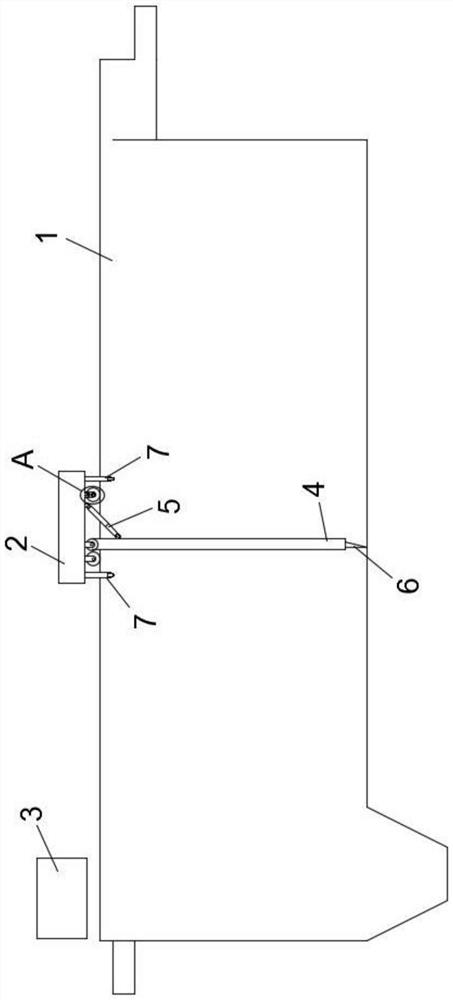

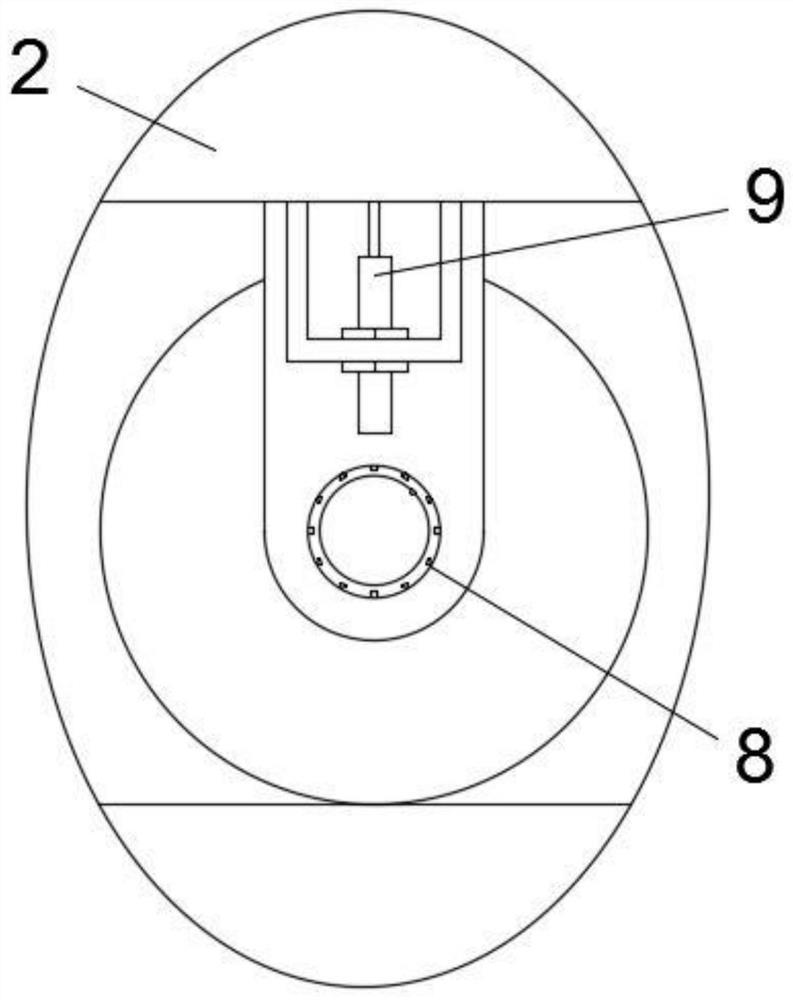

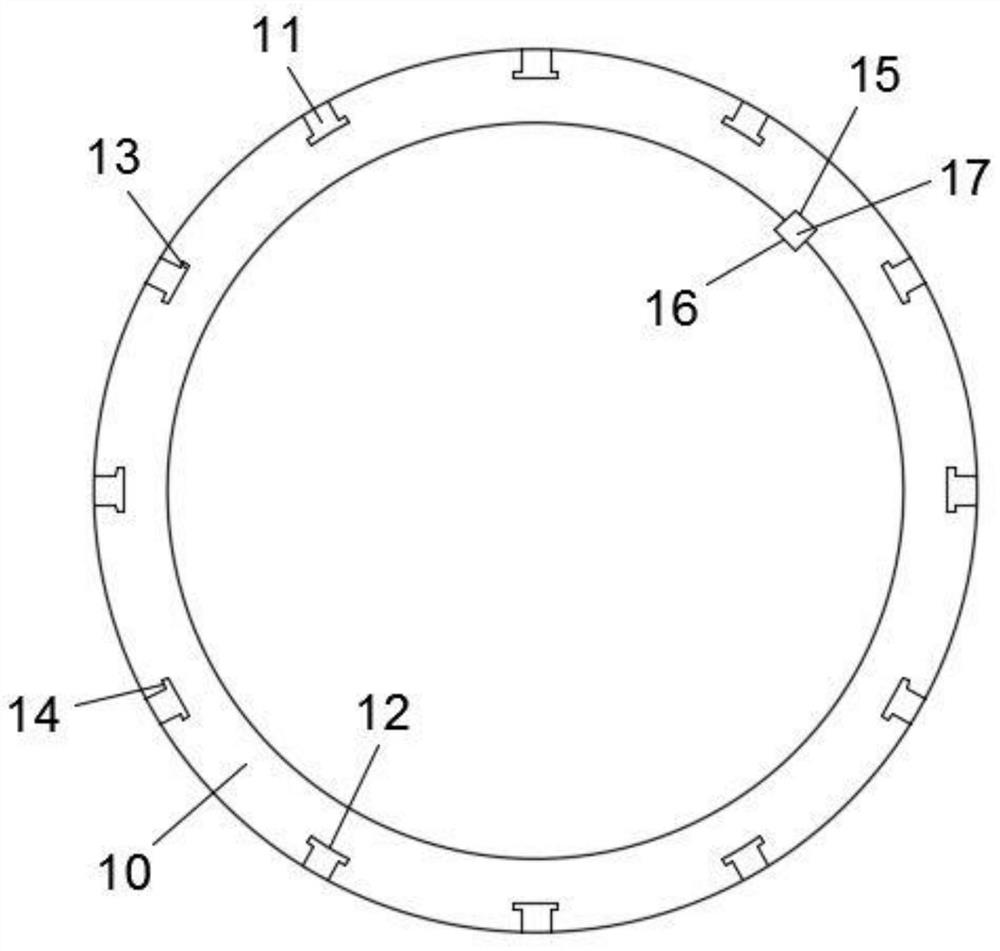

[0019] Such as Figure 1 to Figure 3 As shown, an advection sedimentation tank scraping and suction device of a sewage treatment plant includes an advection sedimentation tank 1, a crane 2, a PLC controller 3, an air-lift sand suction machine (not shown in the figure), an air-lift suction The sand suction pipe of the sand machine is connected with the sand collection hopper of the advection sedimentation tank, and the traveling carriage reciprocates along the length direction of the advection sedimentation pond. The end of the piston rod is hinged to one side of the scraper frame 4, the bottom of the scraper frame 4 is equipped with a scraper 6, and the bottom of the crane 2 is also equipped with two sets of ultrasonic sensors 7 with the probe vertically downward. A calibration ring 8 is installed on the wheel shaft of the vehicle 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com