Punch forming production line

A stamping forming and production line technology, applied in the stamping field, can solve the problems of messy raw materials, molding materials and wastes, affecting the normal operation of stamping and forming production lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following is attached Figure 1-11 The application is described in further detail.

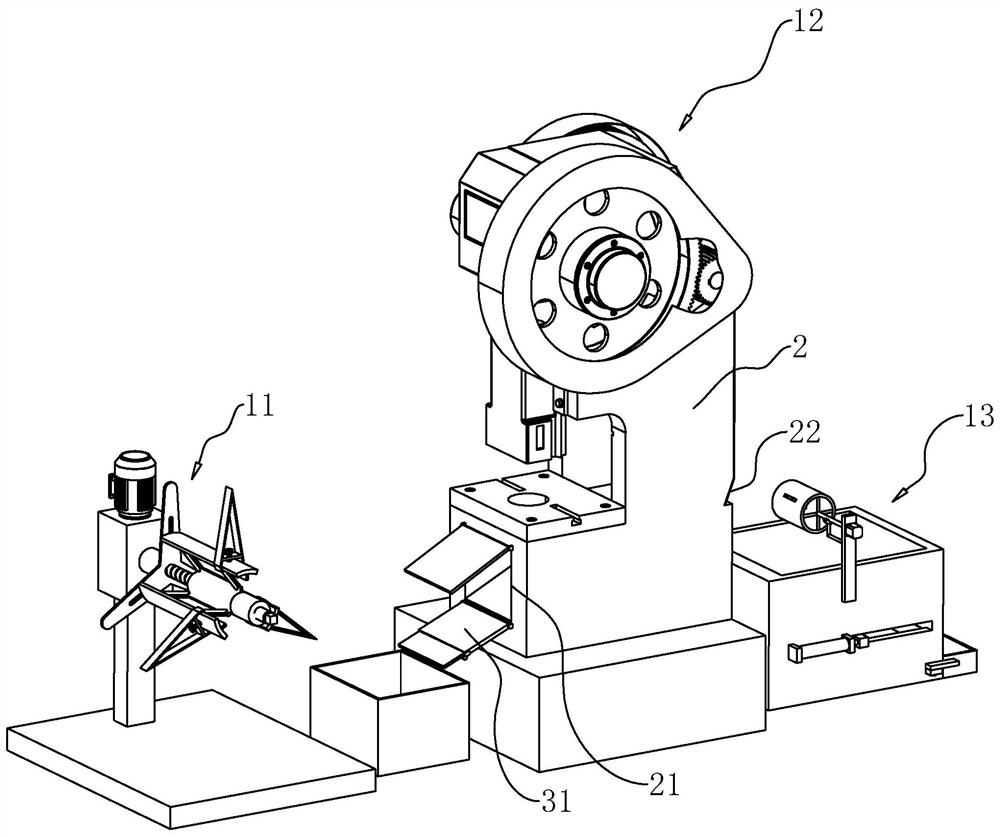

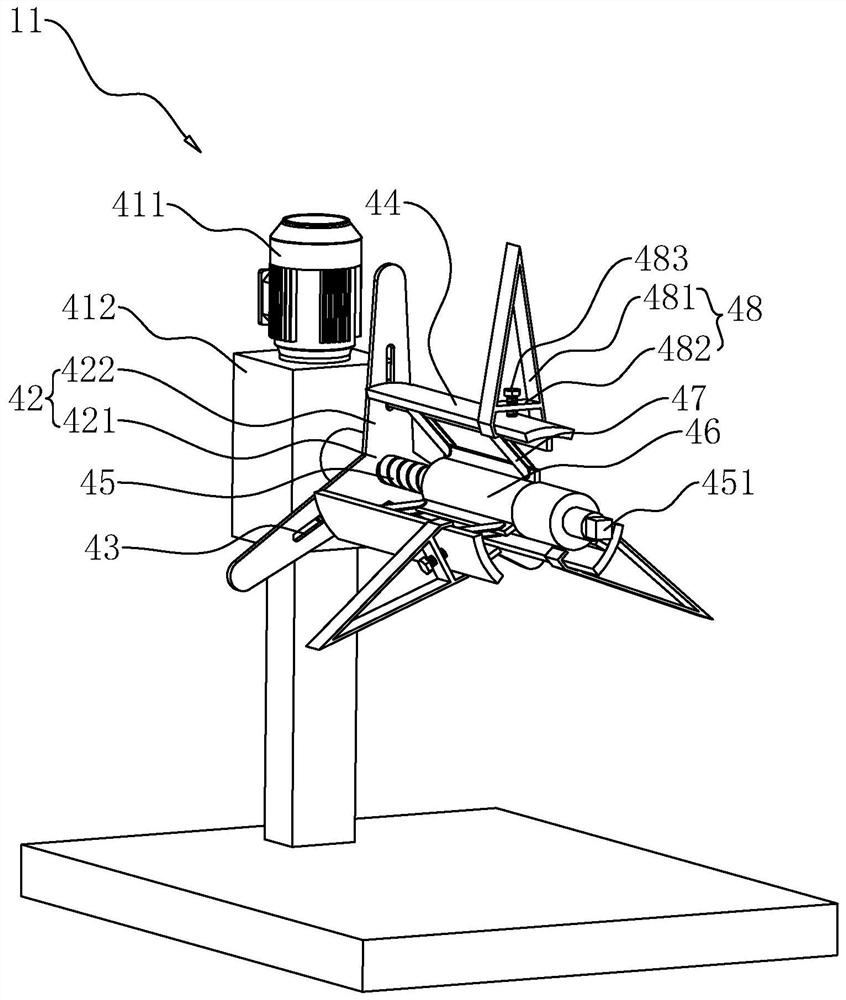

[0057] The embodiment of the present application discloses a stamping forming production line. refer to figure 1 , The stamping and forming production line includes a stamping machine 12, a feeding device 11 and a waste collection and cleaning device for the stamping machine 12.

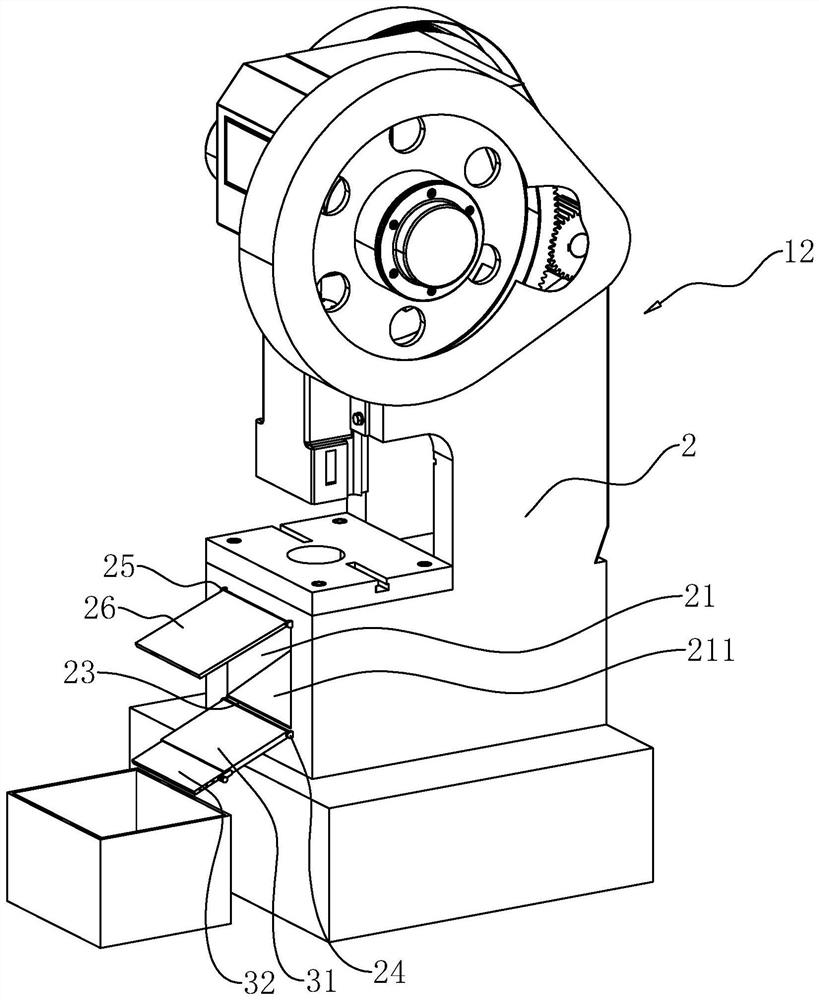

[0058] refer to figure 1 , the stamping machine 12 includes a stamping machine body 2, a discharge port 21 and a discharge port 22, the discharge port 21 and the discharge port 22 are set on the stamping machine body 2, specifically, the discharge port 21 is opened on the stamping machine body 2 The front end of the punching machine body 2, the discharge port 21 is used for the discharge of the formed products punched by the punching machine body 2, and the discharge port 22 is opened at the rear end of the punching machine body 2, and the discharge port 22 is used for the strip material discarding afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com