Liquid spraying device for medium-speed wire cutting and medium-speed wire cutting machine

A liquid spray device and electric cutting technology, which is applied in the direction of electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve the problems of poor chip removal, no distinction, and affecting the processing quality of workpieces, so as to improve processing quality and prevent The effect of broken wire and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

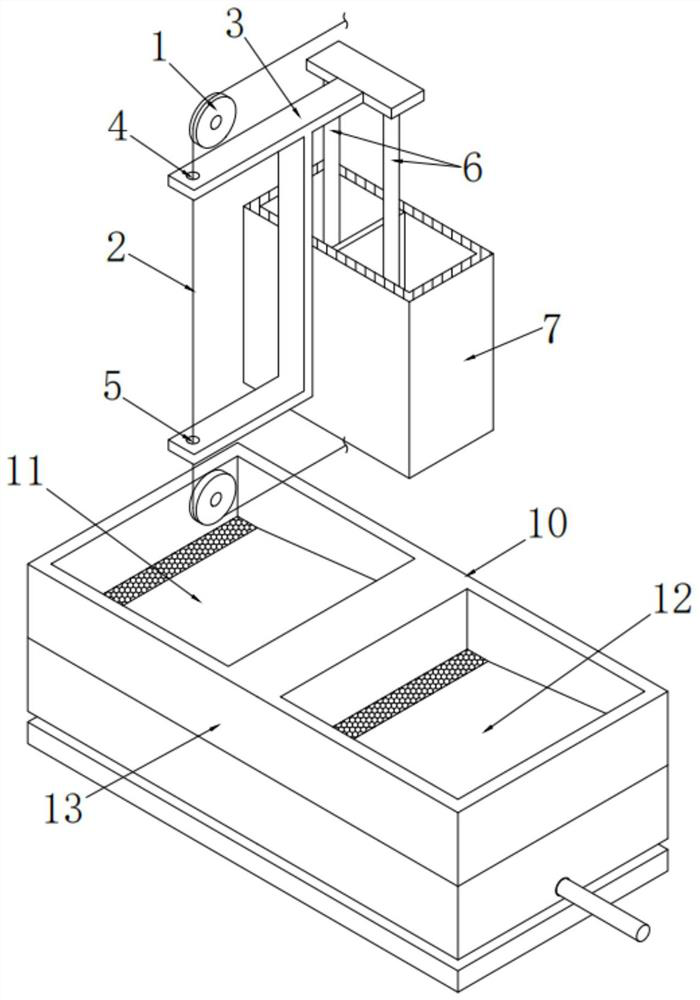

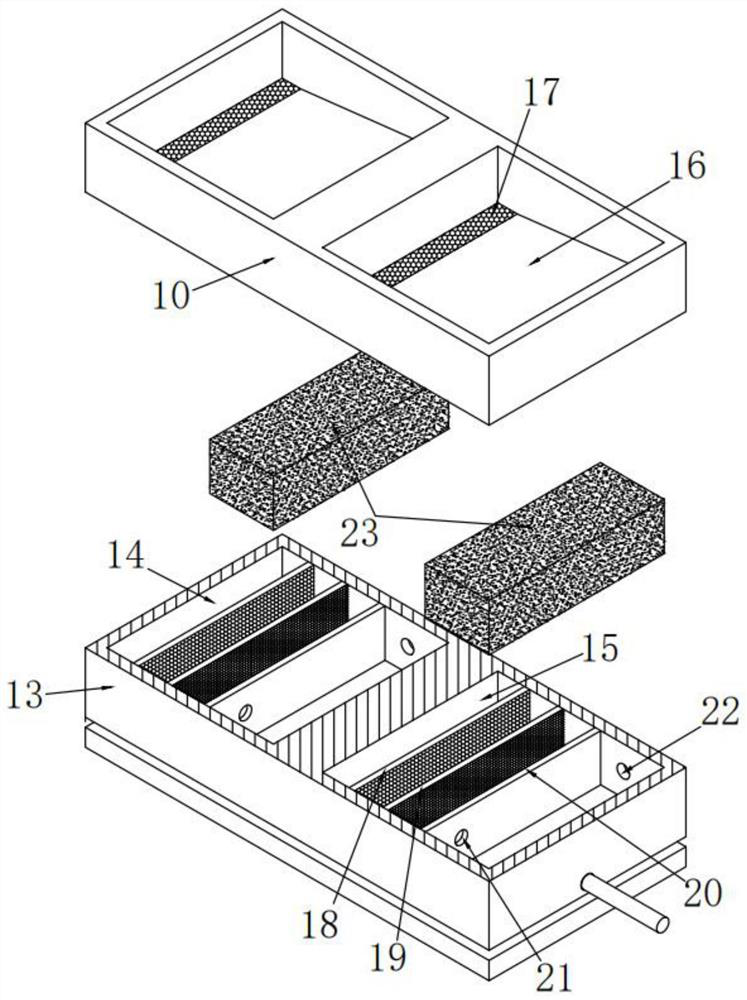

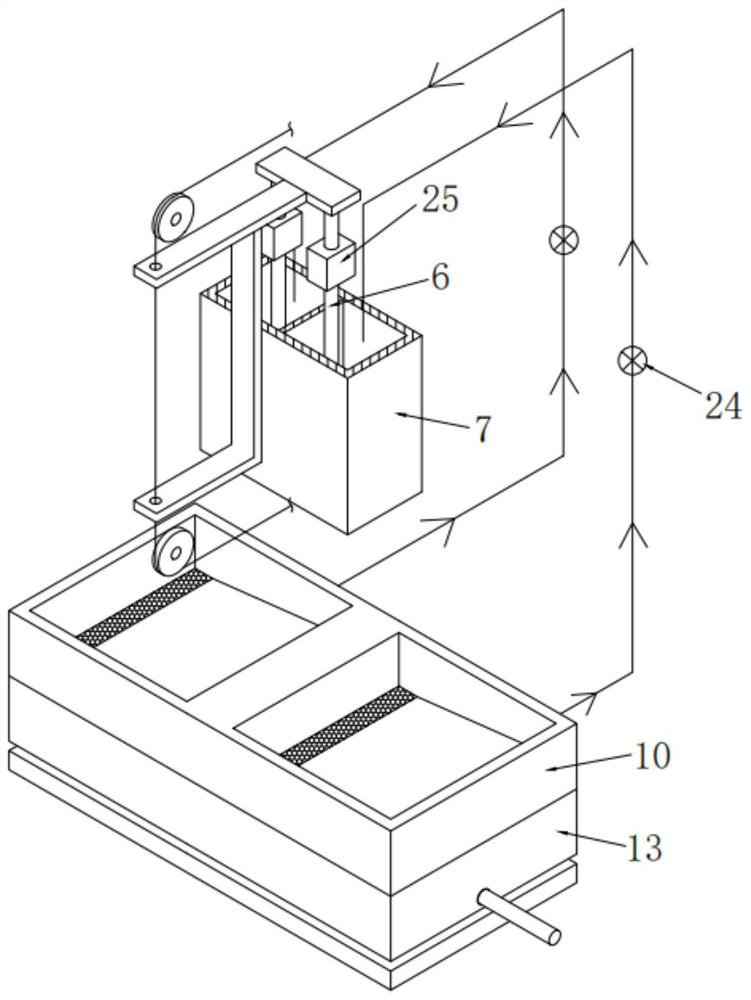

[0031] see Figure 1-7 , the present invention provides a technical solution:

[0032] A liquid spraying device for intermediate wire cutting, comprising a pair of upper and lower wire feeding wheels 1 and an electric cutting molybdenum wire 2 mounted on the wire feeding wheels 1, and a spray frame is fixedly arranged between the upper and lower wire feeding wheels 1 3. The upper spray hole 4 and the lower spray hole 5 are set on the spray frame 3, and both the upper spray hole 4 and the lower spray hole 5 are connected with the spray channel set in the spray frame 3, and the molybdenum wire is cut by electric cutting. 2. It is installed in the upper spray hole 4 and the lower spray hole 5, and the spray rack 3 communicates with the working fluid tank 7 through the delivery pipe 6;

[0033] The working fluid in the working fluid tank 7 enters the spray frame 3 through the delivery pipe 6, and finally sprays out from the upper spray hole 4 and the lower spray hole 5 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com