Self-made banana peel graphene PE-RT super-thermal-conductive anti-scaling floor heating pipe and preparation method thereof

A technology of PE-RT and banana peel, which is applied in the field of floor heating pipes, can solve the problems of high price and unstable quality of graphene production, and achieve the effects of low cost, environmental protection and improved compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

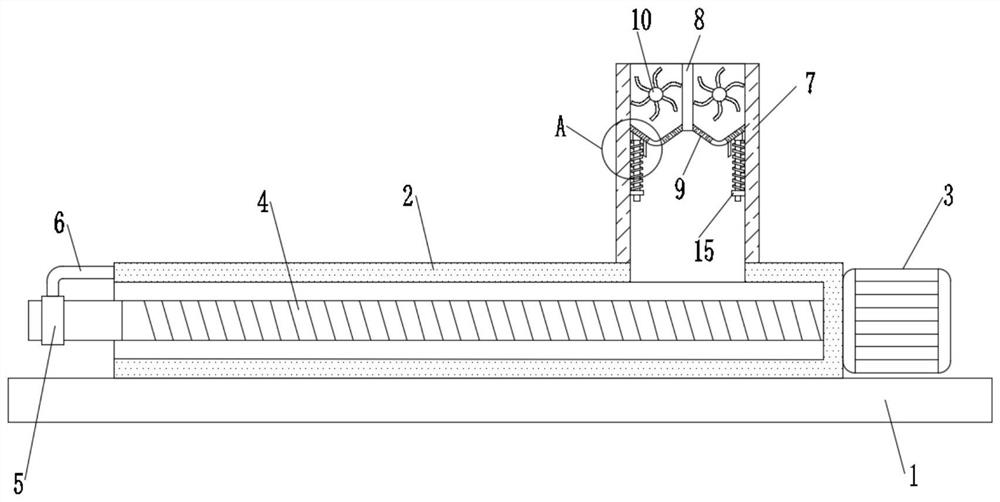

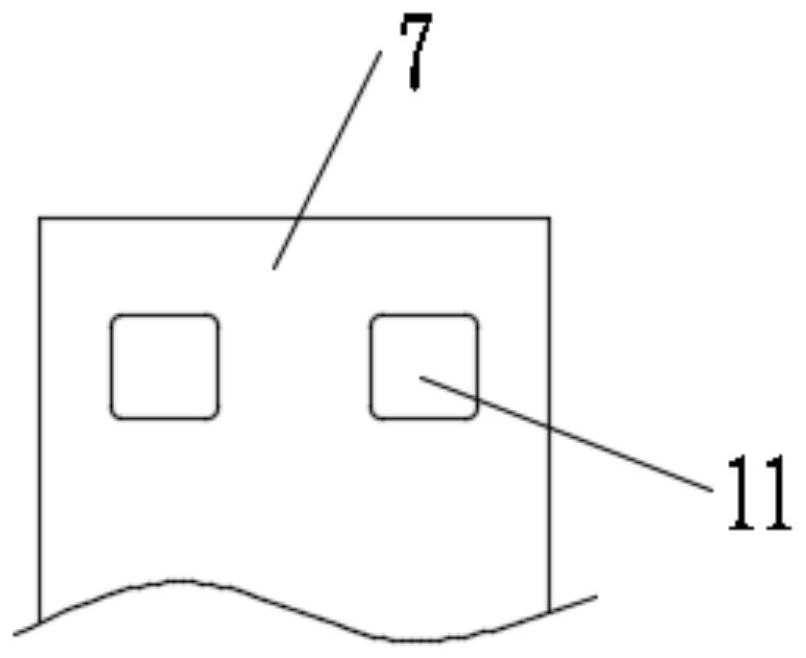

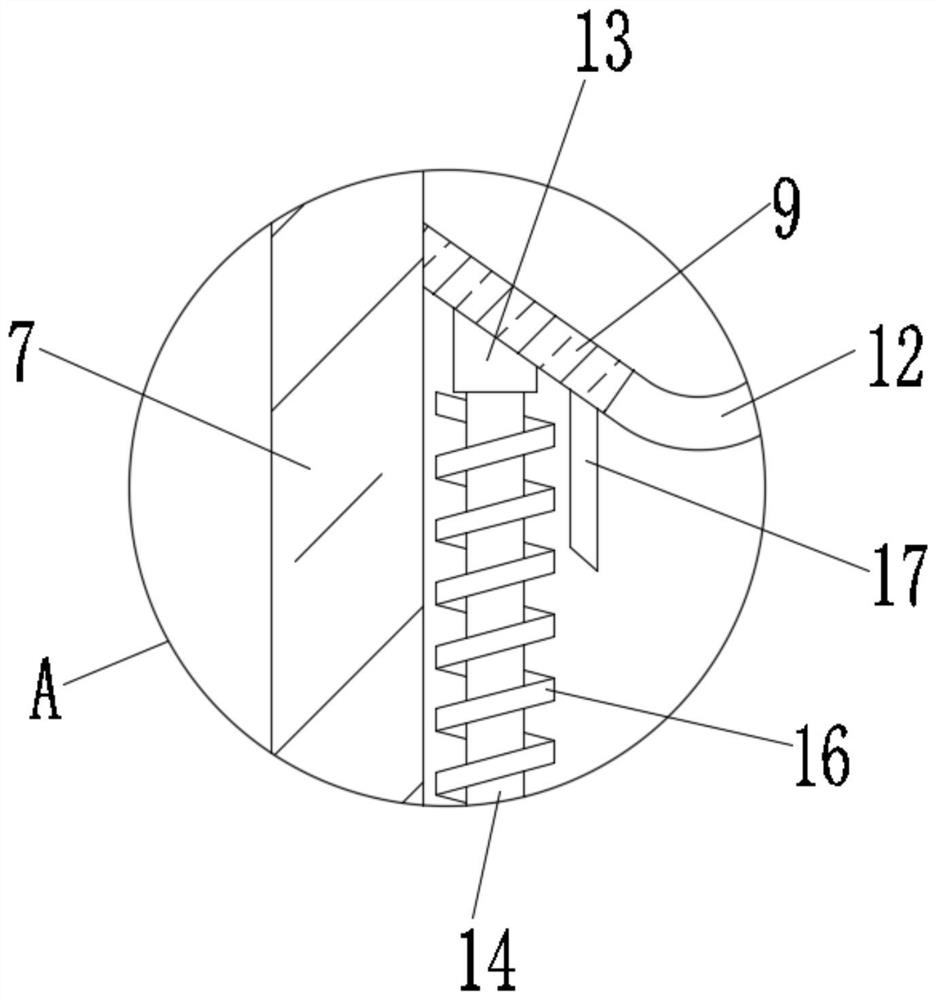

[0031] see Figure 1-3 , the present invention provides a technical solution: a self-made banana peel graphene PE-RT superconducting thermal anti-scaling floor heating pipe, comprising an outer heat-conducting layer and an inner layer anti-scaling layer, the outer heat-conducting layer is made of the following raw materials in parts by mass Ingredients: 100 parts of PE-RT resin, 10 parts of homemade banana peel graphene, homemade banana peel graphene is to wash the collected banana peel with water, soak it in nitrate solution with a concentration of 1mol / L for more than 6 hours, and then take it out Put it in an oven at 80°C for drying, grind the dried banana peel into powder with a pulverizer and add NaOH with a mass ratio of 2%, N 2 Graphene oxide can be obtained by placing the graphite oxide in a tube furnace at 800°C for 2 hours under atmospheric conditions, and putting the obtained graphite oxide in a microwave heating furnace at 1500°C for 1 hour to obtain self-made bana...

Embodiment 2

[0039] see Figure 1-3 , the present invention provides a technical solution: a self-made banana peel graphene PE-RT superconducting thermal anti-scaling floor heating pipe, comprising an outer heat-conducting layer and an inner layer anti-scaling layer, the outer heat-conducting layer is made of the following raw materials in parts by mass Ingredients: 100 parts of PE-RT resin, 25 parts of homemade banana peel graphene, homemade banana peel graphene is to wash the collected banana peel with water, soak it in a nitrate solution with a concentration of 1mol / L for more than 6 hours, and then take it out Put it in an oven at 80°C for drying, grind the dried banana peel into powder with a pulverizer and add NaOH with a mass ratio of 2%, N 2 Graphene oxide can be obtained by placing the graphite oxide in a tube furnace at 800°C for 2 hours under atmospheric conditions, and putting the obtained graphite oxide in a microwave heating furnace at 1500°C for 1 hour to obtain self-made ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com