High-wear-resistance polypropylene material and preparation method thereof

A polypropylene material, high wear-resistant technology, applied in the field of polymer material modification, can solve the problems of low surface hardness, application limitations, and low wear resistance of polypropylene materials, so as to enhance wear resistance and reduce surface friction coefficient , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

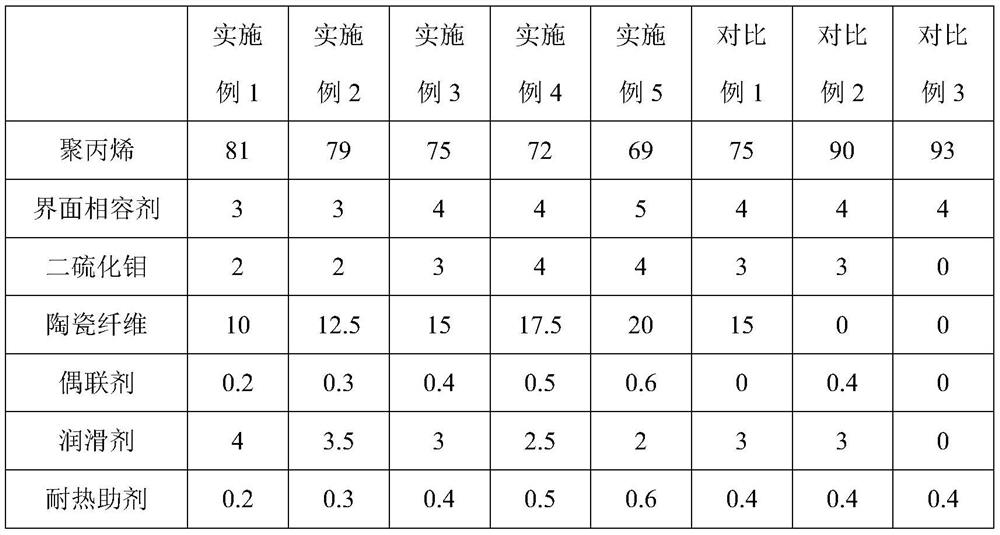

Embodiment 1

[0032](1) The ratio of molybdenum disulfide and ceramic fibers were referred to as the ratio of Table 1, and the ball grinding tank was placed into a powder, the rotational speed of the ball mill was 300 r / min, and the ball milling time was 0.5 hours.

[0033](2) The mixed powder of molybdenum sulfide and ceramic fibers is added to the high mixer together with the coupling agent, and mixed for 3 minutes to obtain a mixed powder.

[0034](3) Put the polypropylene, compatible agent, lubricant and heat-resistant aid by ratio weighing, and mixed with a high-speed mixer for 3 minutes;

[0035](4) The mixture obtained by step (3) is added from the double screw extruder main feed, and the mixed powder obtained by step (2) is added from the twin-screw extruder side feed opening, two mixtures in twin screws. After molten mixing in the extruder, the extrusion strip is cooled to room temperature by the circulating water tank, and after drying after drying, it is dried into the particulating machine t...

Embodiment 2

[0039](1) The ratio of molybdenum sulfide and ceramic fibers were referred to as the ratio of Table 1, and the ball grinding tank was placed into a powder, the rotational speed of the ball mill was 200R / min, and the ball milling time was 1 hour.

[0040](2) The mixed powder of molybdenum sulfide and ceramic fibers is added to the high mixer together with the coupling agent, and mixed for 3 minutes to obtain a mixed powder.

[0041](3) Put the polypropylene, compatible agent, lubricant and heat-resistant aid by ratio weighing, and mixed with a high-speed mixer for 3 minutes;

[0042](4) The mixture obtained by step (3) is added from the double screw extruder main feed, and the mixed powder obtained by step (2) is added from the twin-screw extruder side feed opening, two mixtures in twin screws. After molten mixing in the extruder, the extrusion strip is cooled to room temperature by the circulating water tank, and after drying after drying, it is dried into the particulating machine to obta...

Embodiment 3

[0046](1) The ratio of molybdenum sulfide and ceramic fibers were referred to as the ratio of Table 1, and the ball grinding tank was placed into a powder, and the rotational speed of the ball mill was 400 r / min, and the ball milling time was 0.5 hours.

[0047](2) The mixed powder of molybdenum sulfide and ceramic fibers is added to the high mixer together with the coupling agent, and mixed for 3 minutes to obtain a mixed powder.

[0048](3) A mixture is mixed in a high-speed mixer by polypropylene, compatibilizer, lubricant, and heat-resistant aid by ratio weighing.

[0049](4) The mixture obtained by step (3) is added from the double screw extruder main feed, and the mixed powder obtained by step (2) is added from the twin-screw extruder side feed opening, two mixtures in twin screws. After molten mixing in the extruder, the extrusion strip is cooled to room temperature by the circulating water tank, and after drying after drying, it is dried into the particulating machine to obtain a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com