Stable anti-static liquid and preparation method thereof

An antistatic liquid and stable technology, applied in conductive coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problems of rising surface resistance and reducing antistatic effect, and achieve reduced surface resistance, good antistatic effect, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A preparation method of stable antistatic liquid:

[0054] S1. Mix 4.5kg SIPU-8633 water-based polyurethane emulsion, 4kg isopropanol, 1kg poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonic acid), 0.2kg DMPA-based HDI type water-based polyurethane dispersion and 0.12kg B-83 type defoamer were added into the explosion-proof high-speed disperser, the stirring speed was 1200r / min, and the stirring time was 3h to obtain the premix.

[0055] S2. Add 0.08kg AMP-95 film-forming aid to the premixed solution, continue to stir and disperse for 1 hour, and the stirring rate is 1200r / min to obtain the base solution;

[0056] S3. Add 0.1kg of aziridine curing agent to the base liquid before coating the article, stir and disperse for 0.2h at a stirring rate of 1200r / min to obtain an antistatic liquid, which can be used for coating at this time.

Embodiment 2~ Embodiment 4

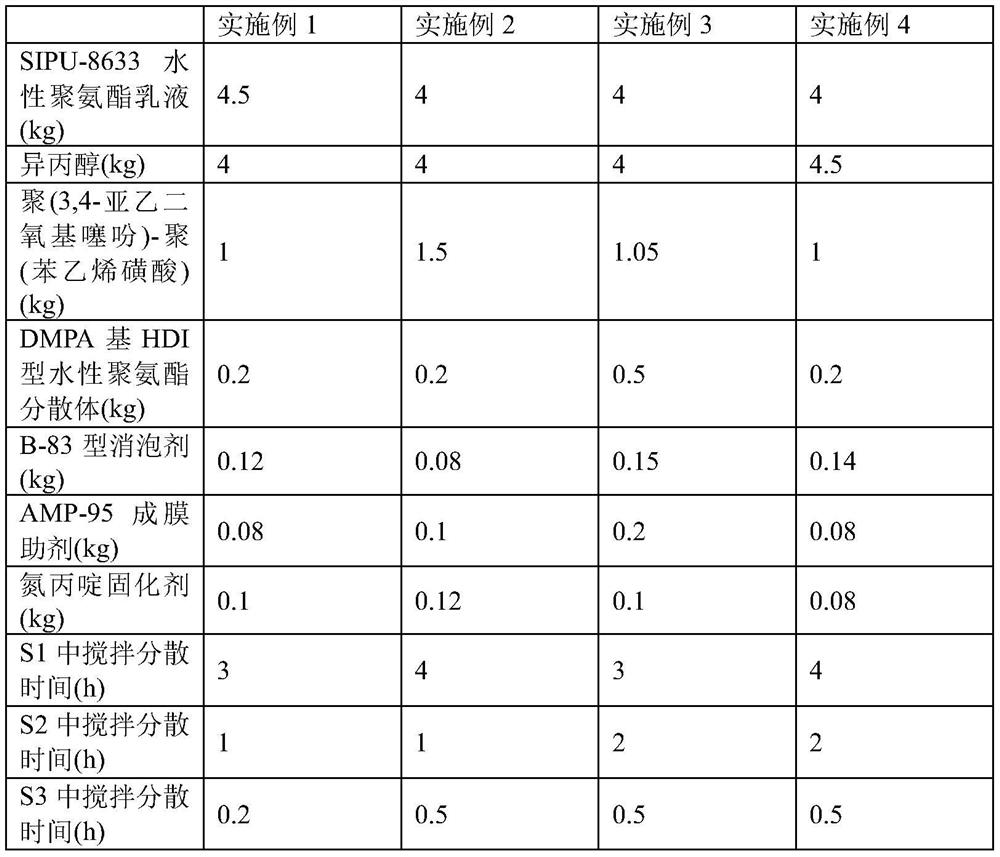

[0058] The difference between embodiment 1, embodiment 2, embodiment 3 and embodiment 4 is shown in table 1.

[0059] Table 1

[0060]

Embodiment 5

[0062] The difference between this embodiment and embodiment 4 is that in this embodiment, the same amount of PU-6696 water-based polyurethane emulsion is used to replace SIPU-8633 water-based polyurethane emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com