Flue purification device modular layout method

A technology of purification device and layout method, which is applied in the direction of combustion method, exhaust gas device, combustion product treatment, etc., to achieve the effects of reducing eddy current, good sealing effect, and easy disassembly and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

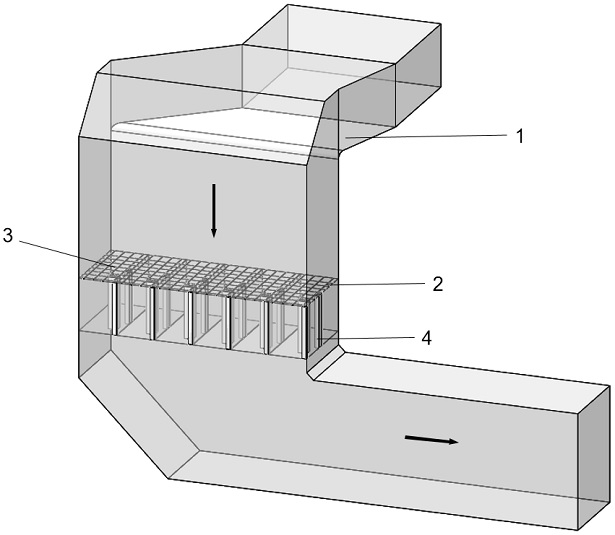

[0024]Seefigure 1 ,2, 5, the present embodiment provides a modular layout method for the flue purification apparatus, arranged in the tail flue 1, and the tail flue 1 includes vertical flue and horizontal flue, select 1 tail flue 1 The vertical flue portion is arranged in the casing module 3, avoiding the elbow, at the size of the head, and the shaped pipe.

[0025]The size of the casing module 3 is designed according to the load, according to the size and flue gas amount of the flue, calculates the number of boxes, using 6 case modules 3, and 6 case modules 3 are arranged in the same plane. And the six case modules 3 are connected to a semi-circular sealing connection method A, and the flow field of the inlet is ensured, and the anti-corrosion is sealed.

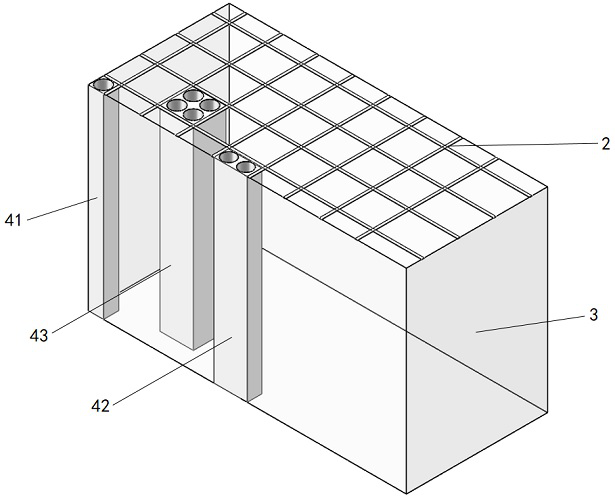

[0026]A support module 2 is provided in the box module 3, and the support module 2 is divided into different regions, and the support module 2 includes an outer support structure and an inner support structure, and the outer support st...

Embodiment 2

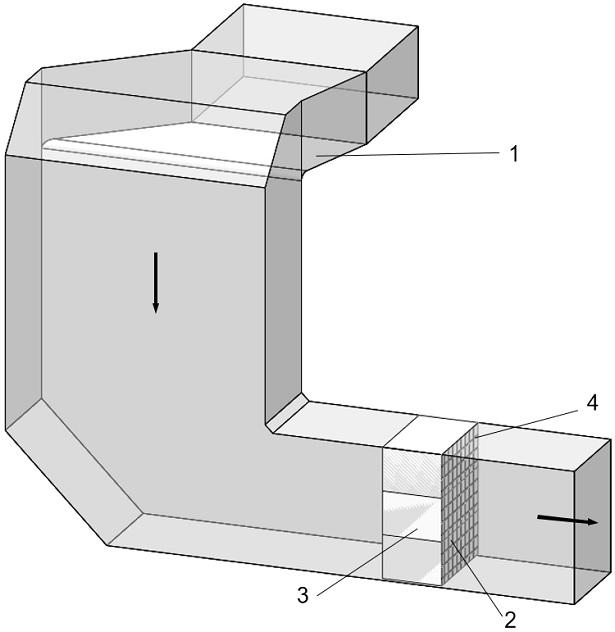

[0030]Seeimage 3 ,4, 5, the present embodiment provides a modular layout method for the flue purification apparatus, arranged in the tail flue 1, and the tail flue 1 includes vertical flue and horizontal flue, select 1 tail flue 1 Horizontal flue partial arrangement of the box module 3, avoid the elbow, the size of the head, and the shaped pipe.

[0031]The size of the box module 3 is designed according to the load, according to the size and flue gas amount of the flue, calculates the number of boxes, using 3 case modules 3, and 3 case modules 3 are arranged in the same plane. And the three case modules 3 use a inferior arc-shaped sealing connection method C to ensure the flow field of the inlet, while sealing the anti-corrosion.

[0032]A support module 2 is provided in the box module 3, and the support module 2 is divided into different regions, and the support module 2 includes an outer support structure and an inner support structure, and the outer support structure is located outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com