Method for measuring curvature radius of APS coating residual stress test piece based on parabola model

A technology of parabolic model and residual stress, applied in measuring devices, force/torque/work measuring instruments, special data processing applications, etc., can solve problems such as difficulty in ensuring uniform deposition, uneven coating stress distribution, and different curvature, etc., to achieve The effect of low equipment cost, high degree of curve fitting and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

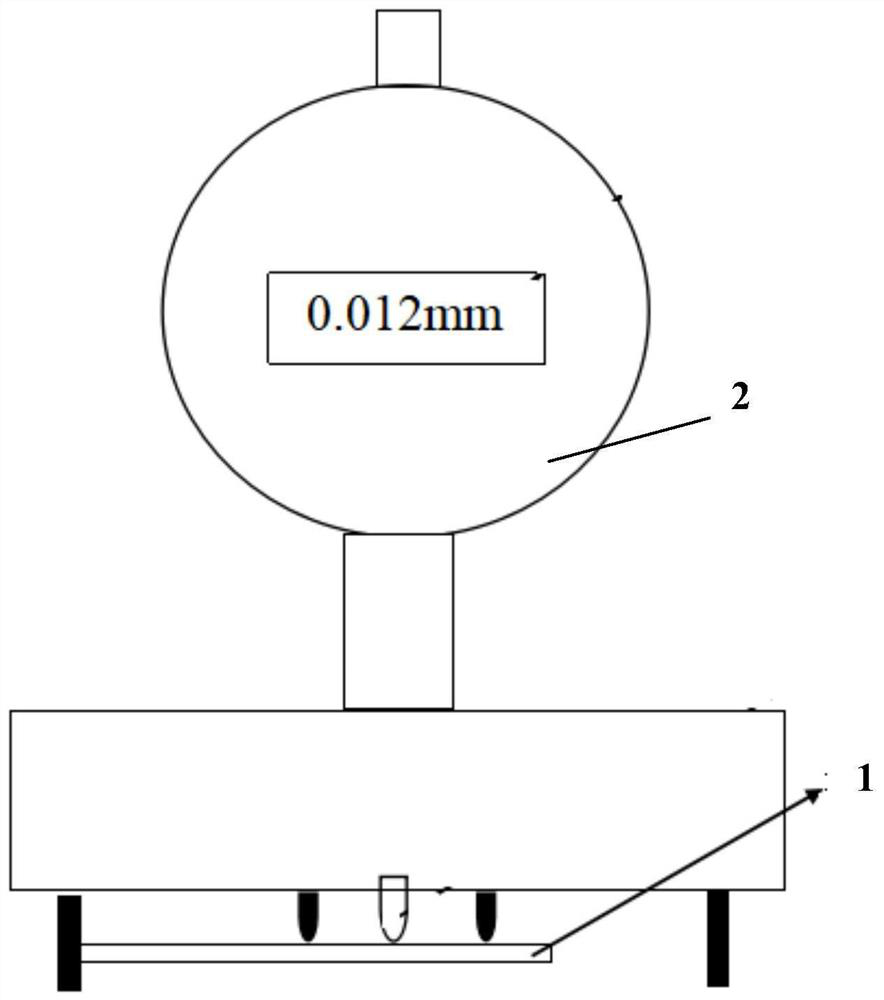

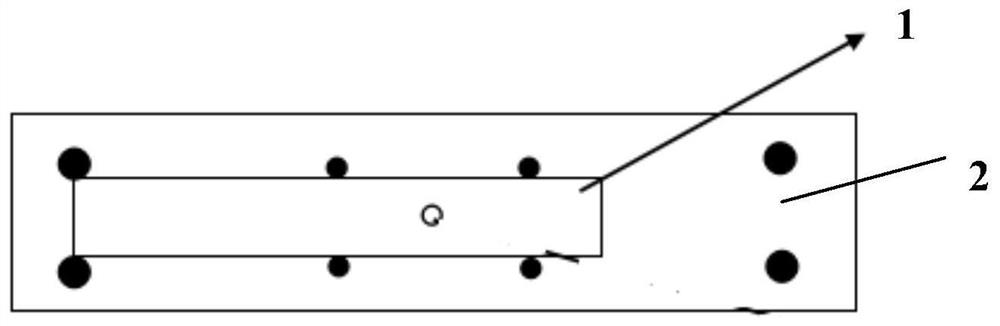

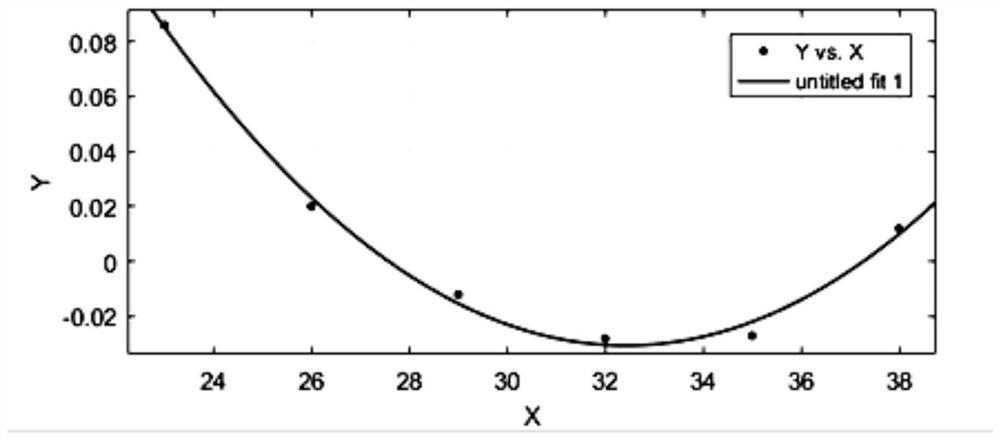

[0024] like figure 1 — image 3 As shown, the method for measuring the radius of curvature of the APS coating residual stress test piece based on the parabolic model provided by the present embodiment includes the following steps carried out in order:

[0025] 1) Preparation of APS coating residual stress test piece: select a nickel-based superalloy with a flat and smooth surface as the substrate, the length, width and height dimensions are 65mm×20mm×2mm, the curvature is guaranteed to be 0, the radius of curvature tends to infinity, and the overall stress is 0. Then plasma spraying is carried out on one side of the substrate to form an APS coating, the thickness of the APS coating is about 200 μm, and cooled to room temperature, thus making the APS coating r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com