Schottky rectifier tube manufacturing method and Schottky rectifier tube

A technology of rectifier tubes and encapsulation shells, which is applied in the field of manufacturing Schottky rectifier tubes, can solve the problems of low processing efficiency and cumbersome procedures, and achieve the effects of high manufacturing efficiency, short time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

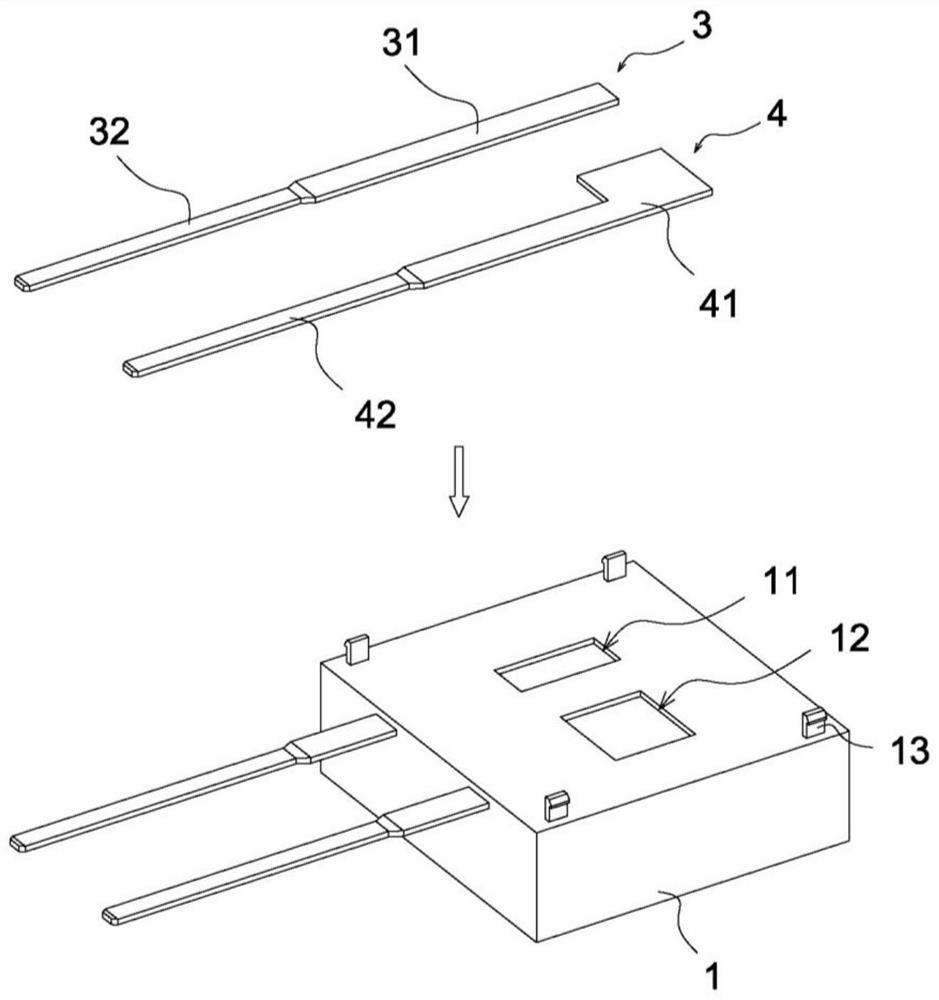

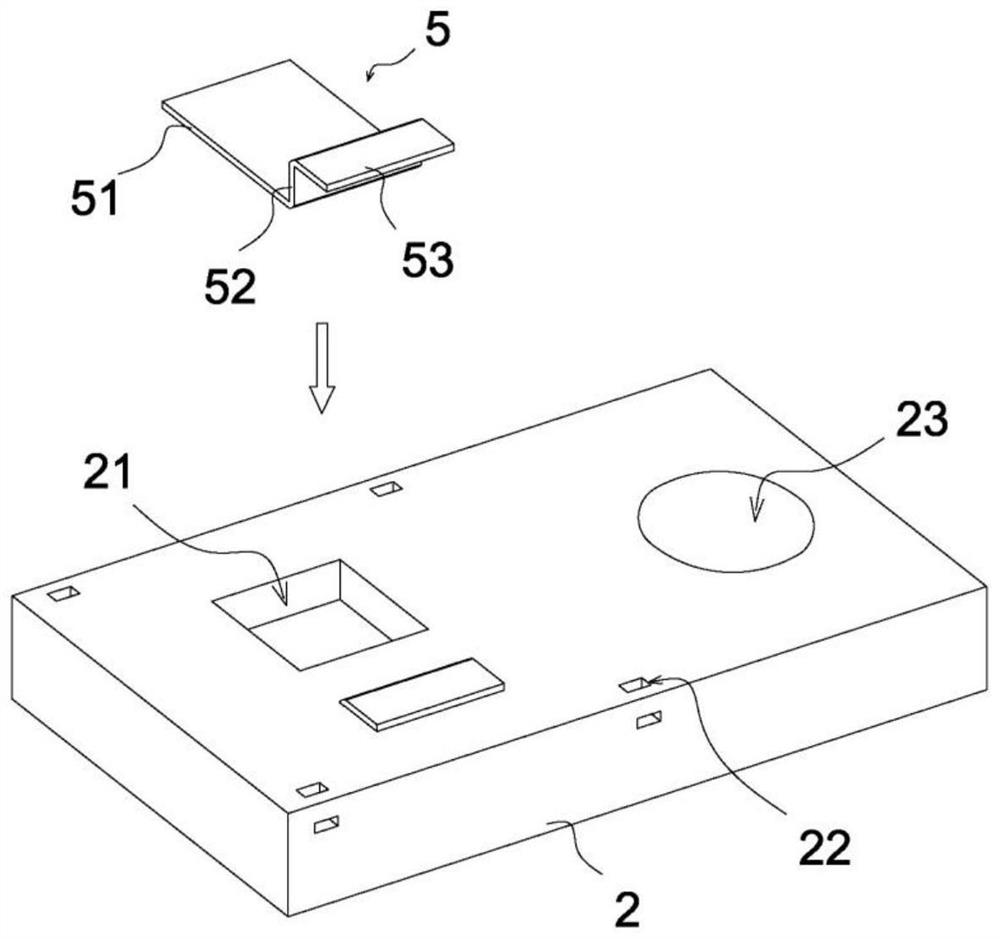

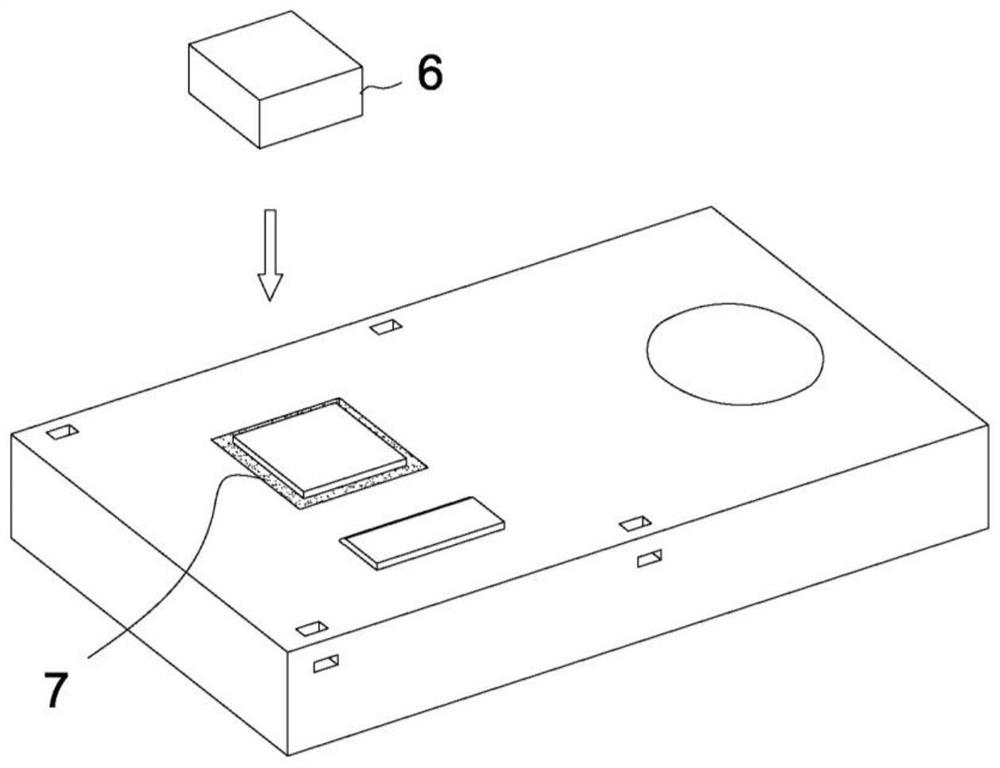

[0027] Such as Figure 1-4 Shown:

[0028] A Schottky rectifier, comprising a first package 1, a second package 2, a first terminal 3, a second terminal 4, a third terminal 5, a Schottky chip 6, the first package 1 and the second The package shell 2 is buckled and connected, the first terminal 3 and the second terminal 4 are integrally formed with the first package shell 1 , the third terminal 5 is integrally formed with the second package shell 2 ; the first terminal 3 includes a first contact portion 31 , the first extension part 32, the first hollow groove 11 is formed on the first package shell 1, the first hollow groove 11 is located on the upper side of the first contact part 31, and the first extension part 32 is located outside the first package shell 1; The terminal 4 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com