Drilling and grinding integrated cutter used for rotational atherectomy of blood vessel calcified tissues, and manufacture method of drilling and grinding integrated cutter

A vascular calcification and cutting tool technology, which is applied in the directions of drilling tool accessories, drilling/drilling equipment, boring machine/drilling machine components, etc. Application range and uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

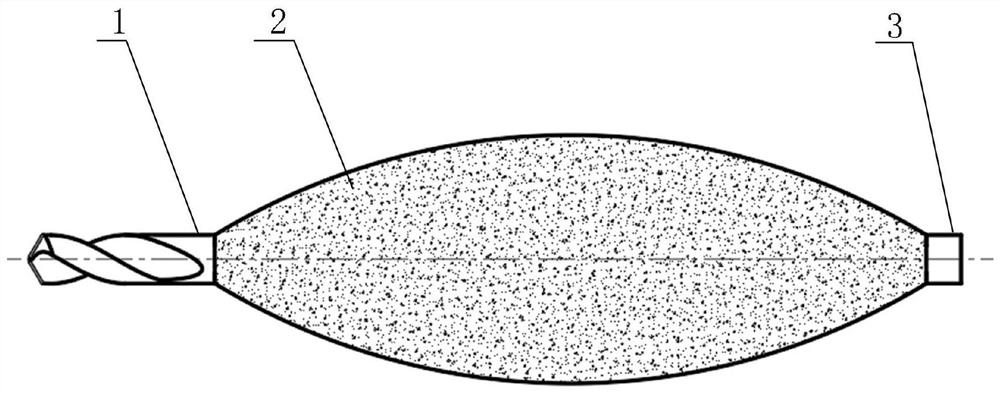

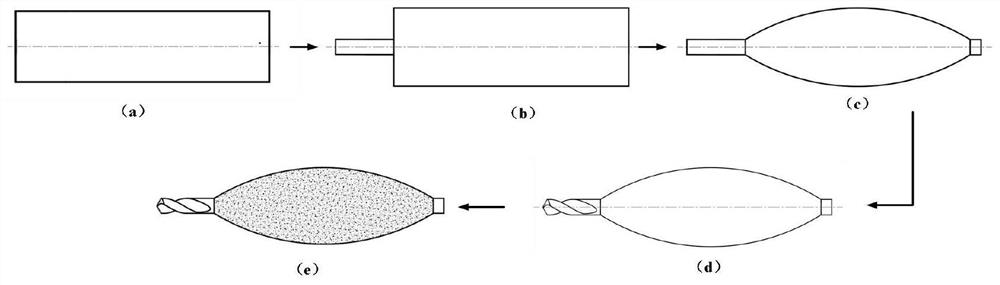

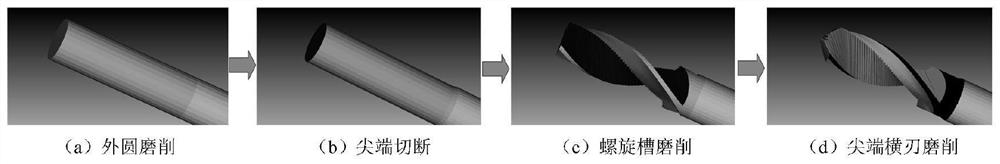

[0025] like figure 1 As shown, a drill-mill integrated tool for rotational atherectomy of vascular calcified tissue is characterized in that it is mainly composed of a micro-drill part 1 , a micro-grind part 2 and a connecting part 3 . Wherein the micro-drill part includes a drill point and a spiral groove, and the micro-grinding head is an olive-shaped electroplated diamond grinding head. When performing rotational atherectomy on severely calcified or completely calcified blood vessels, the micro-drill firstly drills the calcified tissue to ensure that the subsequent micro-abrasion rod can enter the designated position for subsequent rotational atherectomy. The micro-grinding head part 2 is electroplated by the ultrasonic embedding sand method using the prepared abrasive to ensure uniform coating on the surface of the micro-grinding head and improve the efficiency and saf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com