Closed-loop type discarded medical syringe needle processing device

A processing device and syringe technology, applied in the field of medical devices, can solve the problems of easily stabbed transport personnel, disordered needle placement, cross-infection, etc., to avoid the risk of infection, prevent needle tip scratches, and facilitate use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

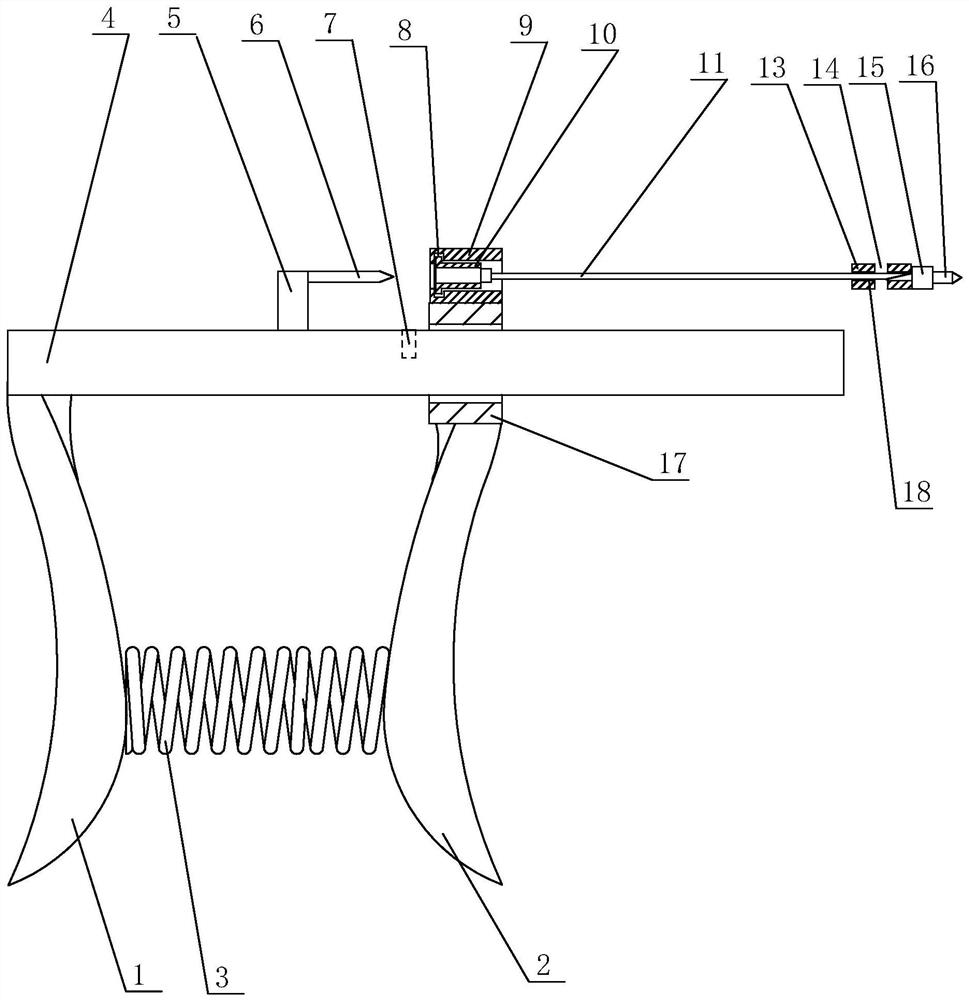

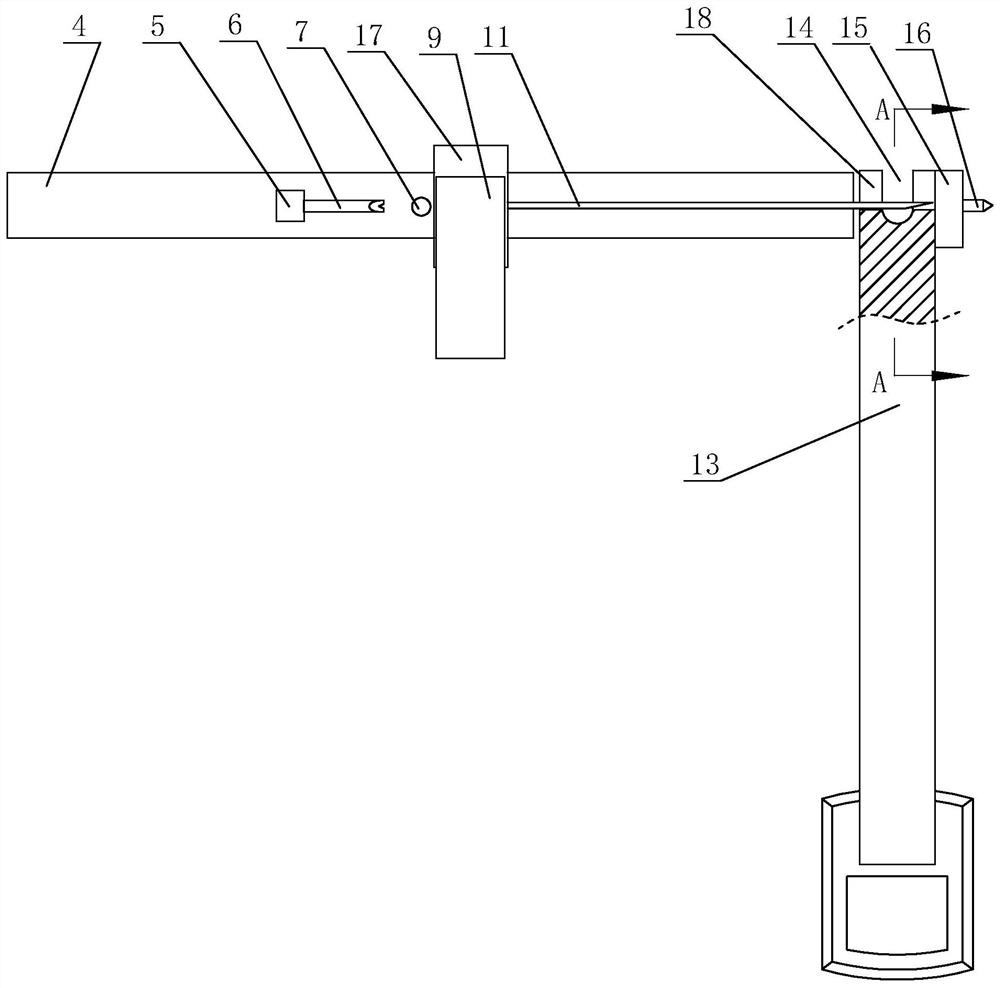

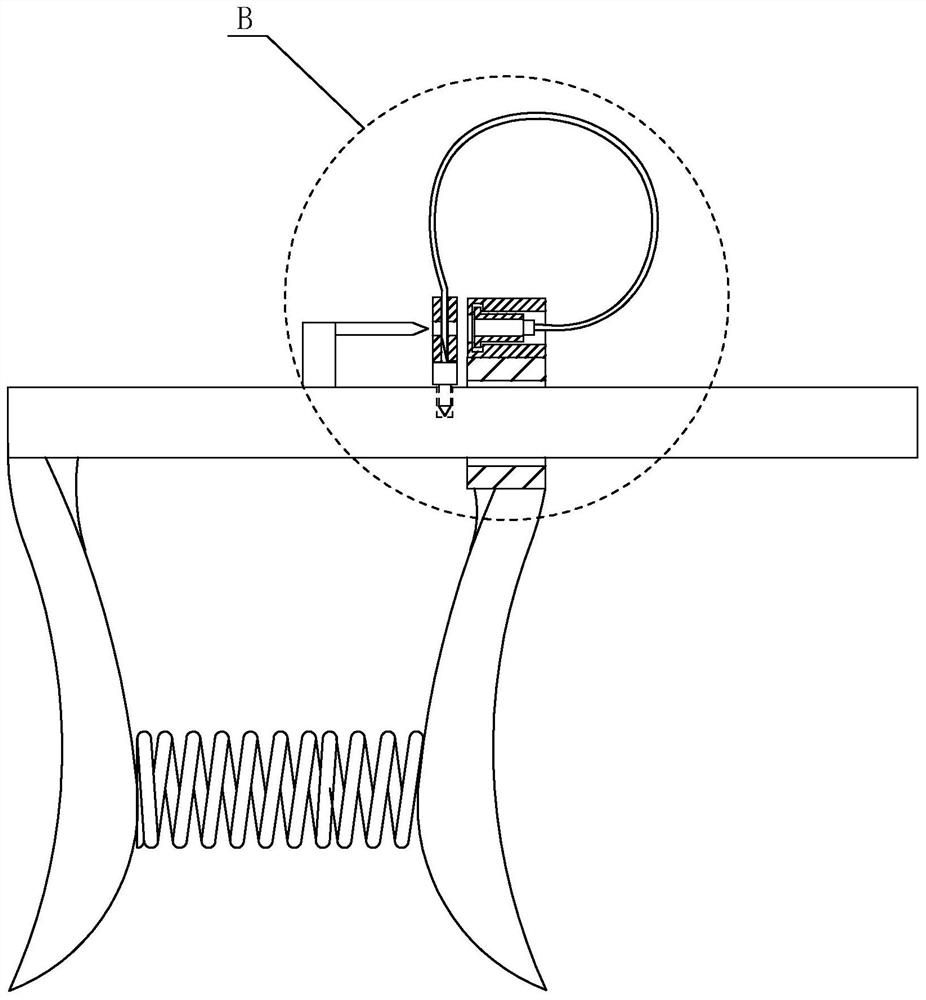

[0026] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0027] Such as Figure 1-Figure 8 As shown, the closed-loop waste medical syringe needle processing device according to the present invention includes a sliding rod 4, a sliding sleeve 17 is set on the sliding rod 4, a fixed handle 1 is fixed at the tail end of the sliding rod 4, and a moving handle 3 is fixed on the sliding sleeve 17. , the positions of the fixed handle 1 and the moving handle 3 are corresponding, the sliding sleeve 17 is fixed on the horizontal U-shaped limit frame 9, and the two inner walls of the limit frame 9 are respectively provided with limit grooves 8, and the positions of the two grooves 8 are corresponding. The inner width of the spacer 9 corresponds to the diameter of the pintle 10, the distance between the two grooves 8 corresponds to the diameter of the annular projection 19 on the needle stem 11, and the opening end of the spacer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com