Preparation method and application of metal monatomic catalytic material M-C3N4 for activating soluble oxidant

A technology of catalytic materials and oxidants, applied in chemical instruments and methods, oxidized water/sewage treatment, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

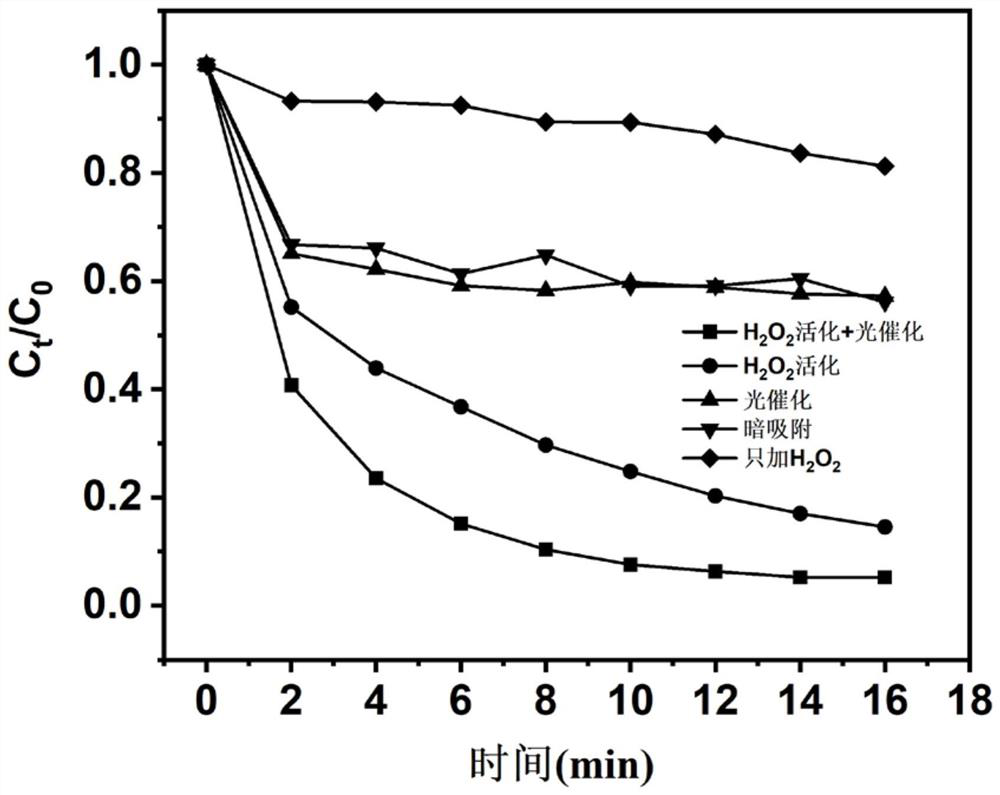

[0019] to combine figure 1 , 50ml concentration is 10mg / L rhodamine B, add 50mg single-atom catalytic material Cu-C 3 N 4 Stir to mix well, add 50 μl of 30% HO 2 o 2 , using a 50W tungsten-halogen lamp for illumination, and taking a sample every 2 minutes to measure the absorbance. Figure 1 Medium Cu-C 3 N 4 activated H 2 o 2 The removal effect of the coupled photocatalytic system can reach 95% in 16 minutes. It can be seen from the figure that Cu-C 3 N 4 activated H 2 o 2 Synergistic with photocatalysis. Its degradation effect is 10% and 52% higher than the removal efficiency under the conditions of activation and photocatalysis alone.

Embodiment 2

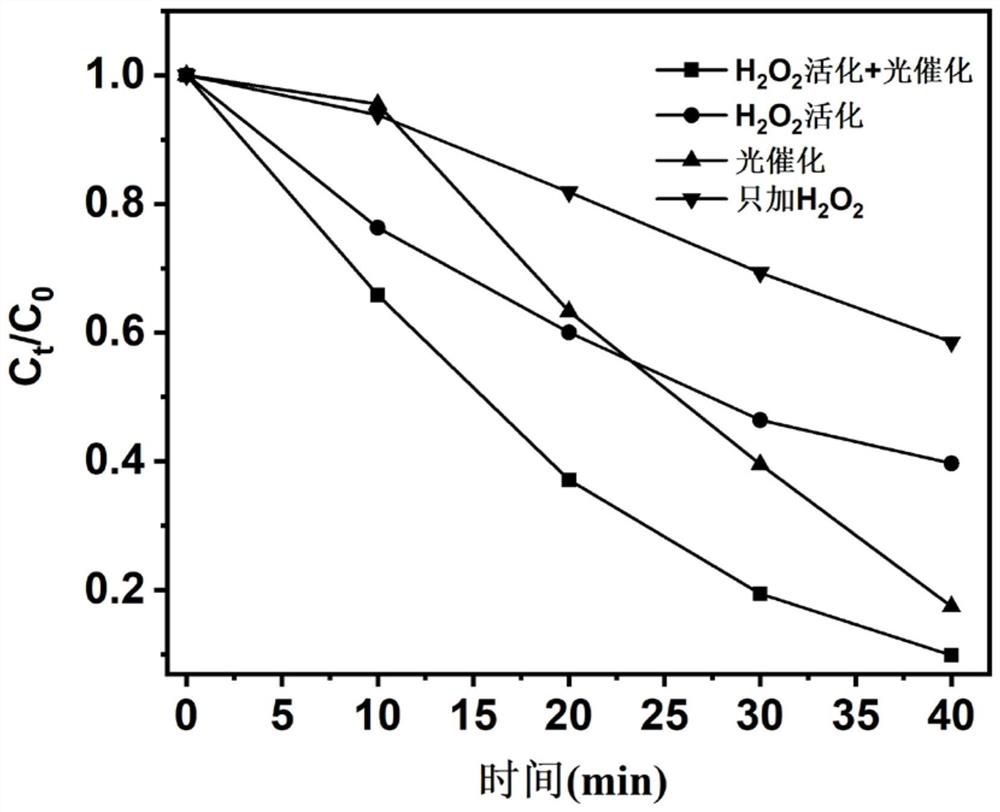

[0021] to combine figure 2 , add 50 μl ethyl acetate to 100ml deionized water, add 50mg single-atom catalytic material Cu-C 3 N 4 Stir to mix well, add 50 μl of 30% HO 2 o 2 , using a 50W halogen tungsten lamp for illumination, and taking a sample every 5 minutes to measure COD. Cu-C 3 N 4 activated H 2 o 2The removal rate of VOC degradation by the coupled photocatalytic system can reach up to 91% in 40 minutes. Its degradation effect is 30% and 6% higher than the removal efficiency under the conditions of activation and photocatalysis alone.

Embodiment 3

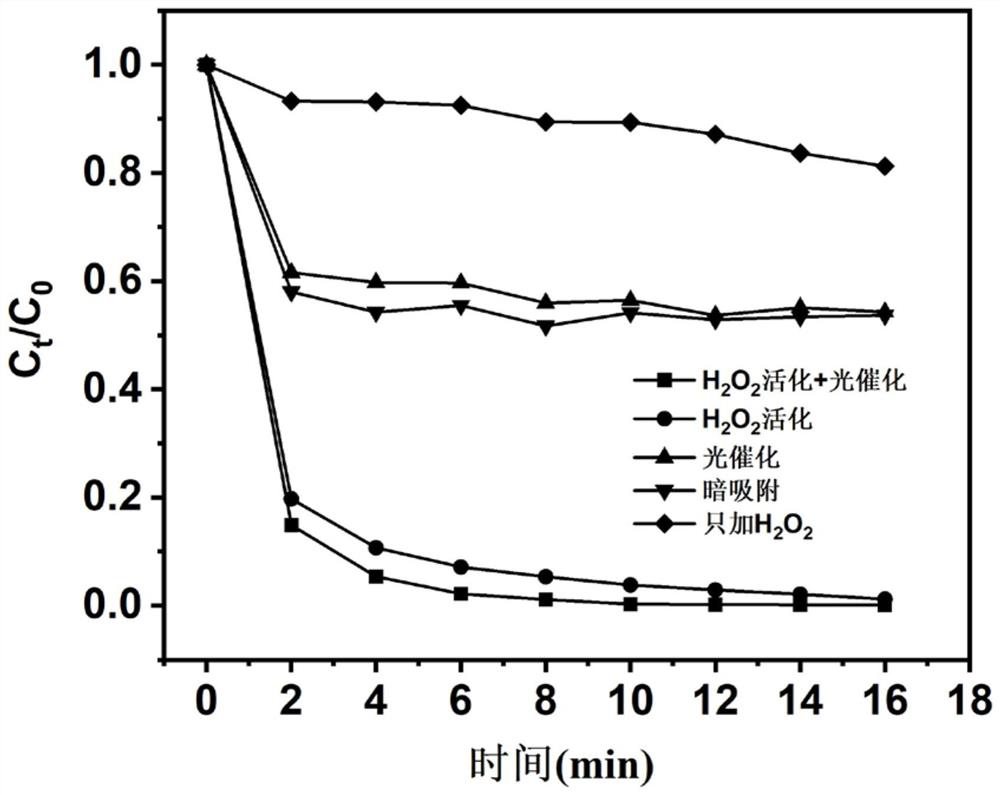

[0023] combine image 3 , 50ml concentration is 10mg / L rhodamine B, add 20mg single-atom catalytic material Co-C 3 N 4 Stir and mix evenly, add 50 microliters of PMS with a concentration of 100mM, use a 50W tungsten halogen lamp for illumination, and take a sample every 2 minutes to measure the absorbance. Co-C 3 N 4 The efficiency of the activated PMS-coupled photocatalytic system to degrade rhodamine B can reach 99.9% within 16 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com