Surface coating process for processing fire-fighting equipment

A technology of fire-fighting equipment and surface coating, which is applied to the device for coating liquid on the surface, pre-treatment surface, coating, etc., which can solve the problems of short anti-corrosion time, poor anti-corrosion ability, and poor degreasing effect, and achieve extended use Long service life, stable performance, and the effect of increasing the coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

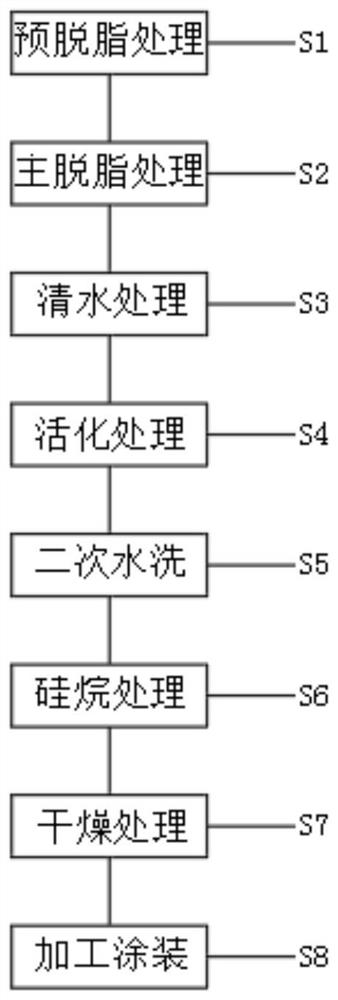

[0031] see Figure 1-2 , a surface coating process for fire-fighting equipment processing, comprising the following steps:

[0032] S1: Pre-degreasing treatment. The surface of the fire-fighting equipment is rinsed by a flushing device. The water temperature is 60°C, the flushing time is 1min, and the flushing pressure is 0.15Mpa. The degreasing liquid is sprayed on the surface of the fire-fighting equipment by the flushing device for pre-degreasing For treatment, the degreasing liquid is made of degreasing agent mixed with water, the temperature of the degreasing liquid is 50°C, the free alkalinity of the degreasing liquid is 25pt, the spraying pressure is 0.15Mpa, and the spraying time is 1.5min;

[0033] S2: Main degreasing treatment. The fire-fighting equipment treated in S1 is immersed in a degreasing tank filled with degreasing liquid for degreasing soaking treatment. There is a stirring device inside the tank to ensure that the degreasing tank liquid is even and in con...

Embodiment 2

[0047] see Figure 1-2 , a surface coating process for fire-fighting equipment processing, comprising the following steps:

[0048] S1: Pre-degreasing treatment. The surface of the fire-fighting equipment is rinsed by a flushing device. The water temperature is 80°C, the flushing time is 1min, and the flushing pressure is 0.18Mpa. The degreasing liquid is sprayed on the surface of the fire-fighting equipment by the flushing device for pre-degreasing For treatment, the degreasing liquid is made of degreasing agent mixed with water, the temperature of the degreasing liquid is 70°C, the free alkalinity of the degreasing liquid is 35pt, the spraying pressure is 0.18Mpa, and the spraying time is 1.5min;

[0049] S2: Main degreasing treatment, immerse the fire-fighting equipment after S1 treatment in a degreasing tank filled with degreasing liquid for degreasing soaking treatment, the free alkalinity of the degreasing liquid is 30-40pt, the temperature of the degreasing liquid is 70...

Embodiment 3

[0063] see Figure 1-2 , a surface coating process for fire-fighting equipment processing, comprising the following steps:

[0064] S1: Pre-degreasing treatment. The surface of the fire-fighting equipment is rinsed by a flushing device. The water temperature is 70°C, the flushing time is 1min, and the flushing pressure is 0.17Mpa. The degreasing liquid is sprayed on the surface of the fire-fighting equipment by the flushing device for pre-degreasing For treatment, the degreasing liquid is made of degreasing agent mixed with water, the temperature of the degreasing liquid is 58°C, the free alkalinity of the degreasing liquid is 28pt, the spraying pressure is 0.17Mpa, and the spraying time is 1.5min;

[0065]S2: Main degreasing treatment. Immerse the fire-fighting equipment after S1 treatment in a degreasing tank filled with degreasing liquid for degreasing soaking treatment. There is a stirring device inside the tank to ensure that the degreasing tank liquid is even and in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com