Production process of high-strength Ti75 titanium ring

A production process and high-strength technology, used in manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problem of insufficient strength of Ti75 titanium rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

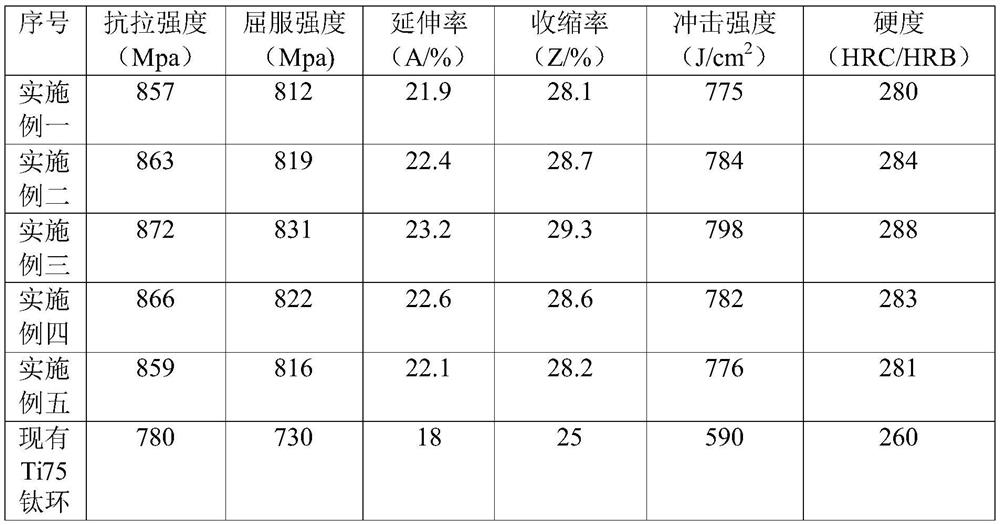

Examples

Embodiment 1

[0031] A kind of production technology of the high intensity Ti75 titanium ring, comprises the following steps:

[0032] (1) Incoming material: Check the grade and specification of the incoming material, and weigh it with an electronic scale;

[0033] (2) Inspection: flaw detection, riser detection, and inspection of the surface for metallurgical defects;

[0034] (3) The first fire, billet forging, using 4500T equipment, preheating at 750°C for 1.8 hours and then raising the temperature to 1110°C, holding time for 400min, keeping the heating rate at 10°C / min during the heating process, after completing two upsetting and three drawing It can be returned to the furnace to open the billet, and carry out air cooling and grinding. According to the finished product specifications, it can be sawed and cut into two types according to the single weight: 1# single weight ≥ 390kg two pieces, 2# single weight ≥ 330kg two pieces, and unloading;

[0035] (4) The second fire, using 2000T e...

Embodiment 2

[0042] A kind of production technology of the high intensity Ti75 titanium ring, comprises the following steps:

[0043] (1) Incoming material: Check the grade and specification of the incoming material, and weigh it with an electronic scale;

[0044] (2) Inspection: flaw detection, riser detection, and inspection of the surface for metallurgical defects;

[0045] (3) The first fire, billet forging, using 4500T equipment, preheating at 780°C for 1.9 hours, then raising the temperature to 1120°C, holding time 415min, and keeping the heating rate at 10°C / min during the heating process, after completing two upsetting and three drawing It can be returned to the furnace to open the billet, and carry out air cooling and grinding. According to the finished product specifications, it can be sawed and cut into two types according to the single weight: 1# single weight ≥ 390kg two pieces, 2# single weight ≥ 330kg two pieces, and unloading;

[0046] (4) The second fire, using 2000T equi...

Embodiment 3

[0053] A kind of production technology of the high intensity Ti75 titanium ring, comprises the following steps:

[0054] (1) Incoming material: Check the grade and specification of the incoming material, and weigh it with an electronic scale;

[0055] (2) Inspection: flaw detection, riser detection, and inspection of the surface for metallurgical defects;

[0056] (3) The first fire, billet forging, using 4500T equipment, preheating at 800°C for 2 hours, then raising the temperature to 1130°C, holding time 440min, keeping the heating rate at 10°C / min during the heating process, after completing two upsetting and three drawing It can be returned to the furnace to open the billet, and carry out air cooling and grinding. According to the finished product specifications, it can be sawed and cut into two types according to the single weight: 1# single weight ≥ 390kg two pieces, 2# single weight ≥ 330kg two pieces, and unloading;

[0057] (4) The second fire, using 2000T equipment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com