Mortar composite material for repairing historic building, and preparation method thereof

A technology for composite materials and ancient buildings, applied in the field of mortar composite materials for repairing ancient buildings and their preparation, can solve the problems of poor toughness, resistance to brittle fracture, and the inability of natural hydraulic lime to meet high strength, so as to improve adhesion and The effect of toughness, toughness improvement, and ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] According to another aspect of the present invention, a kind of preparation method of mortar composite material for repairing ancient buildings according to the present invention is provided, comprising:

[0041] The inorganic cementitious material composition, the epoxy resin composition, river sand and water are mixed to prepare the mortar composite material for restoring ancient buildings.

[0042] Four variables are involved in the preparation process of the mortar composite material for restoration of medieval buildings in the present invention: the amount of epoxy resin composition, the mass fraction of fly ash in the inorganic cementitious material composition, the amount of polyvinyl alcohol fiber added, the amount of epoxy resin The amount of curing agent in the resin composition is divided into three groups according to the values of the variables. In the 3 groups of schemes, the epoxy resin composition accounting for 5%, 20%, and 30% of the total mass of th...

example 1

[0053] Epoxy resin composition dosage (accounting for the ratio of inorganic cementitious material composition gross mass): 5%

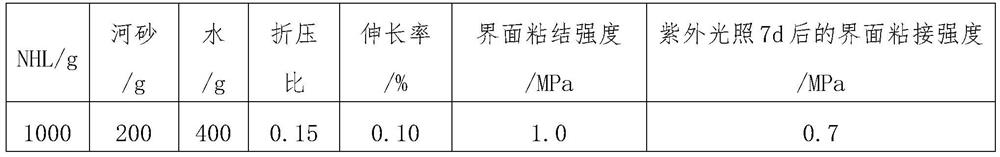

[0054] Table 3 Mortar composite material ratio and experimental indicators

[0055]

[0056]

[0057] It should be noted that the serial numbers 1), 2), and 3) in the column of the above-mentioned epoxy resin composition represent the epoxy resin compositions of different proportions in Table 1 "the proportion of epoxy resin composition with different curing agent content" For the resin composition, the value should be taken according to the amount of epoxy resin monomer.

example 2

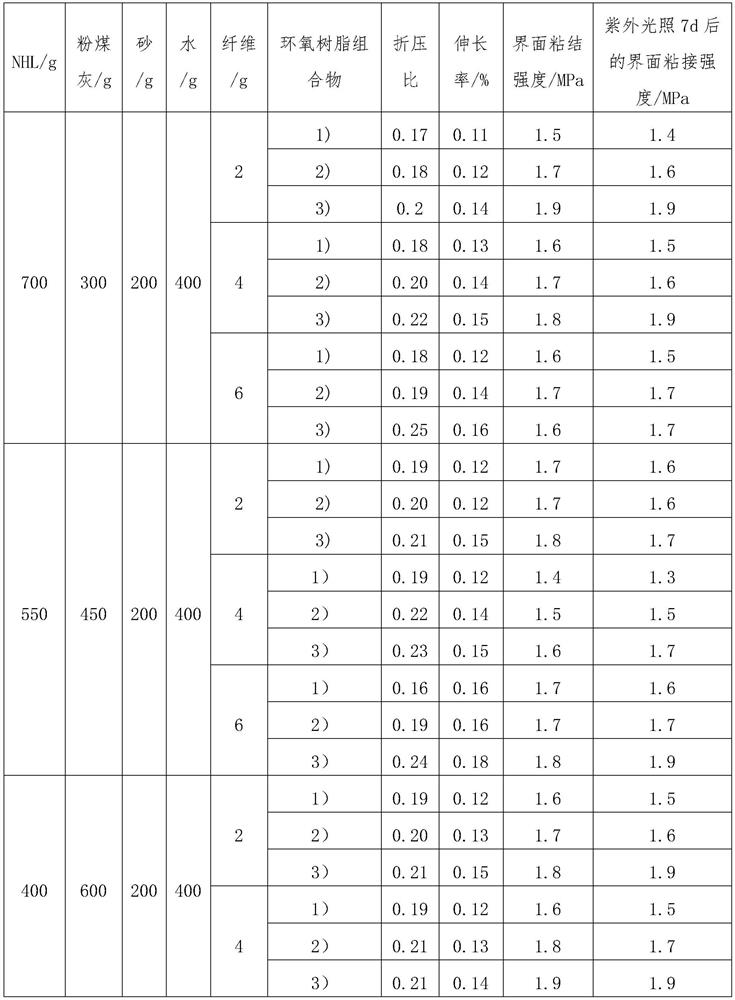

[0059] Epoxy resin composition dosage (accounting for the ratio of inorganic cementitious material gross mass): 20%

[0060] Table 4 Mortar composite ratio and experimental indicators

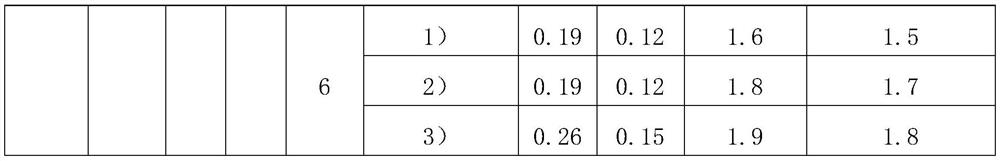

[0061]

[0062]

[0063] It should be noted that the serial numbers 1), 2), and 3) in the column of the above-mentioned epoxy resin composition represent the epoxy resin compositions of different proportions in Table 1 "the proportion of epoxy resin composition with different curing agent content" For the resin composition, the value should be taken according to the amount of epoxy resin monomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com