Amino Alcohol Composite Rust Inhibitor and Its Application

An amino alcohol and rust inhibitor technology, applied in the field of anti-corrosion of building steel bars, can solve the problems of large amount of phosphate and carbonate rust inhibitors, low construction efficiency, poor environmental adaptability, etc. Insufficiency of rust inhibition performance, effect of improving concrete performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

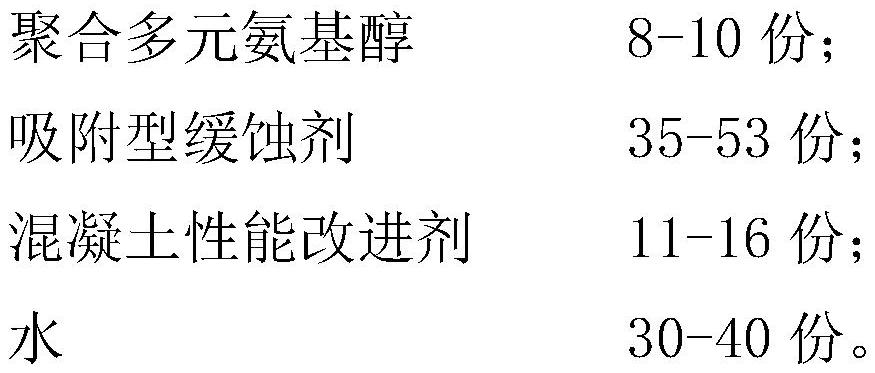

[0057] Weigh the raw materials of the amino alcohol composite rust inhibitor according to the following mass parts ratio, mix and stir the raw materials, and control the stirring time for 10 minutes.

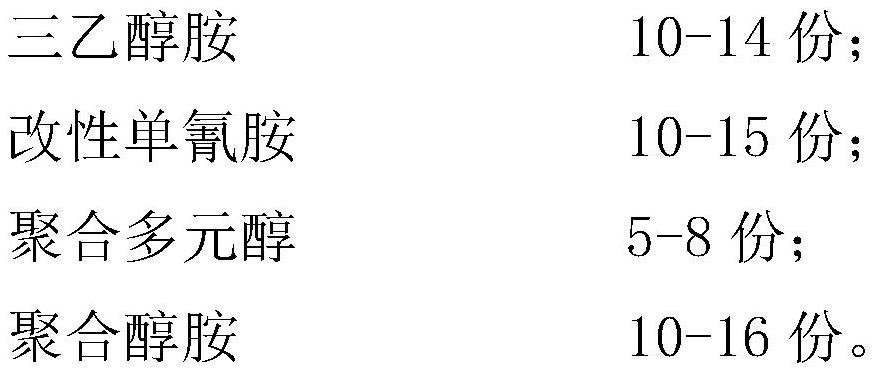

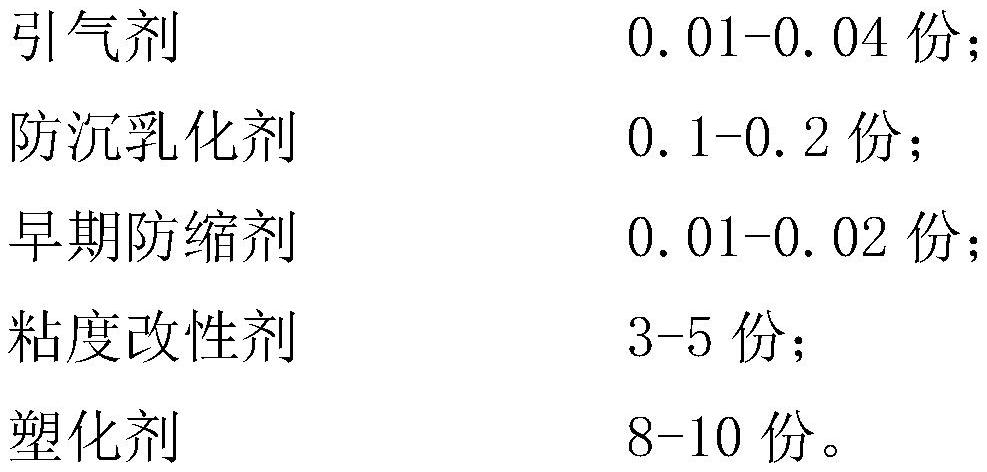

[0058] 8 parts of polymerized polyamino alcohol, 10 parts of triethanolamine, 12 parts of modified cyanamide, 8 parts of polymerized polyol, 11 parts of polymerized alcohol amine, 0.025 parts of rosin saponin air-entraining agent, anti-sedimentation emulsifier 0.1 part of sodium pyrophosphate, 0.01 part of carboxymethyl cellulose ether for early anti-shrinkage agent, 3 parts of polycarboxylate thickener for viscosity modifier, 8 parts of polycarboxylate superplasticizer for plasticizer, Add 40 parts of water.

[0059] Prepare benchmark concrete according to the C35 concrete ratio.

[0060] The amino alcohol composite rust inhibitor prepared in this example is mixed in an amount of 5% of the cementitious material by mass percentage (external mixing method), and the performance t...

Embodiment 2

[0062] Weigh the raw materials of the amino alcohol composite rust inhibitor according to the following mass parts ratio, mix and stir the raw materials, and control the stirring time for 10 minutes.

[0063] 10 parts of polymerized polyamino alcohol, 13 parts of triethanolamine, 10 parts of modified cyanamide, 6 parts of polymerized polyol, 16 parts of polymerized alcohol amine, 0.01 part of alkylsulfonate air-entraining agent, anti-settling The emulsifier uses 0.2 parts of sodium stearate, the early anti-shrinkage agent uses 0.015 parts of dextrin, the viscosity modifier uses 5 parts of polycarboxylate thickener, and the plasticizer uses 10 parts of polycarboxylate water reducer. 30 servings.

[0064] Prepare benchmark concrete according to the C35 concrete ratio.

[0065] The amino alcohol composite rust inhibitor prepared in this example is mixed in an amount of 5% of the cementitious material by mass percentage (external mixing method), and the performance test data of t...

Embodiment 3

[0067] Weigh the raw materials of the amino alcohol composite rust inhibitor according to the following mass parts ratio, mix and stir the raw materials, and control the stirring time for 10 minutes.

[0068] 8.5 parts of polymerized polyamino alcohol, 14 parts of triethanolamine, 15 parts of modified cyanamide, 5 parts of polymerized polyol, 10 parts of polymerized alcohol amine, air-entraining agent using 0.03 parts of rosin resin air-entraining agent, anti-sedimentation emulsifier using 0.2 parts of sodium lauryl sulfate, 0.02 parts of polysaccharide as early anti-shrinkage agent, 5 parts of polycarboxylate thickener as viscosity modifier, 10 parts of polycarboxylate superplasticizer as plasticizer, and 33 parts of water .

[0069] Prepare benchmark concrete according to the C35 concrete ratio.

[0070] The amino alcohol composite rust inhibitor prepared in this example is mixed in an amount of 5% of the cementitious material by mass percentage (external mixing method), an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com