UV top-coat paint, preparation method and application thereof

A clear topcoat and coating technology, applied in the field of coatings, can solve the problems of low solid content of coatings, poor gloss stability, poor surface leveling, etc., and achieve the effects of high transparency, high curing efficiency, and fast leveling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below through specific examples.

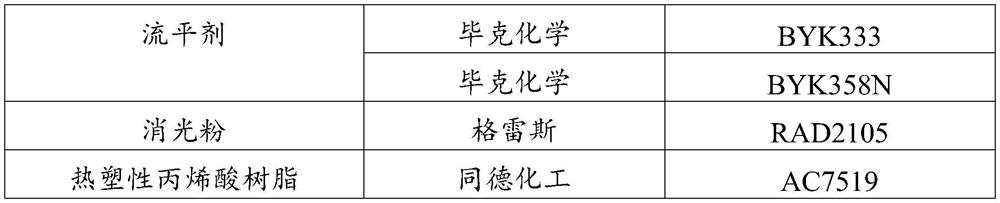

[0031] The sources of raw materials used in Examples 1-4 of the present invention and Comparative Examples 1-3 are shown in Table 1 below.

[0032] Table 1. The sources of raw materials used in Examples 1-4 and Comparative Examples 1-3

[0033]

[0034]

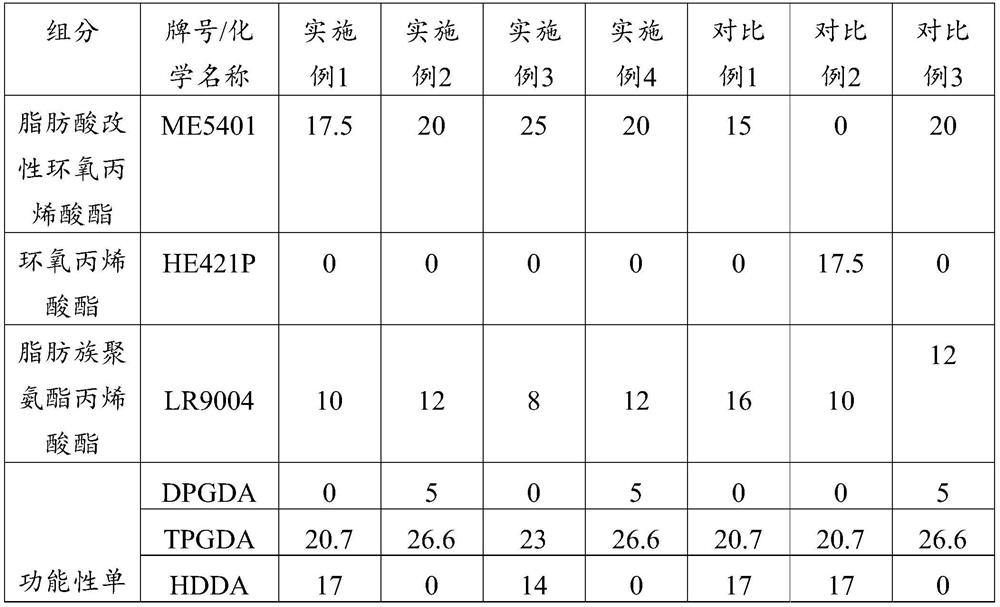

[0035] The raw material components of Examples 1-4 and Comparative Examples 1-3 are shown in Table 2. The UV clear topcoat coating of embodiment 1-4, comparative example 1-3 is prepared as follows:

[0036] (1) Weigh each component by parts by weight, put fatty acid modified epoxy acrylate, aliphatic urethane acrylate, and functional monomers with a mass fraction of 20% into the dispersing cylinder at a speed of 600-800rpm / min Disperse for 5-10 minutes;

[0037] (2) Put the photoinitiator, dispersant, leveling agent and defoam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com