Chlorine-free low-base-number calcium sulfonate detergent and preparation method thereof

A low base value calcium sulfonate and detergent technology, applied in the direction of additives, petroleum industry, lubricating compositions, etc., can solve problems such as shortening, lower base value of oil products, and affecting oil performance, achieving good results and reducing The effect of total base number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

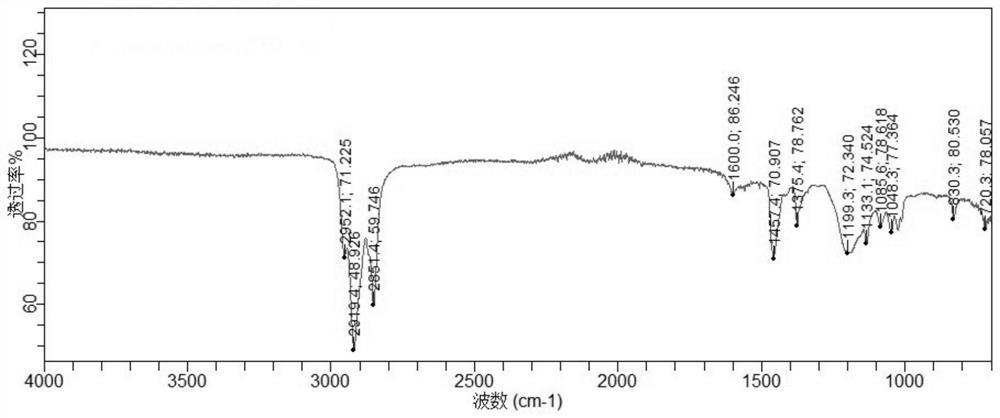

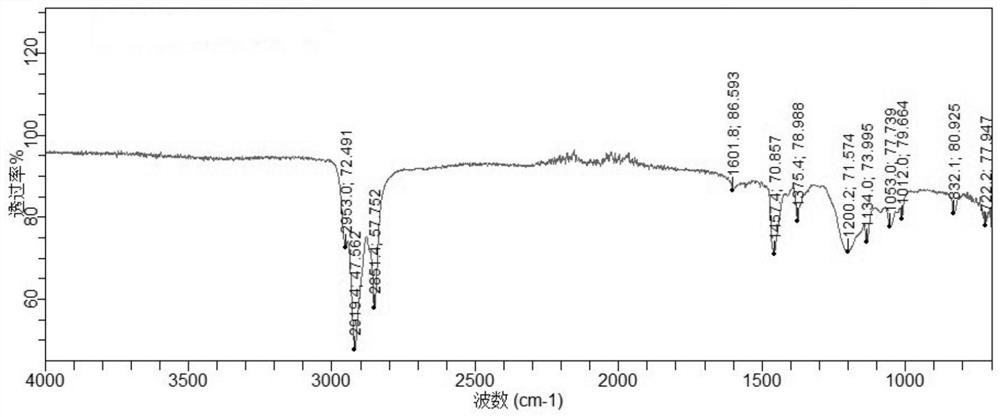

Image

Examples

Embodiment 1

[0027] Add 39 parts of toluene, 1 part of organic amine, 30 parts of base oil 150SN, 5 parts of calcium oxide and 25 parts of alkylbenzenesulfonic acid into 3m 3 In the workshop reaction kettle, stir at a constant temperature of 55°C at a speed of 500r / min for about 3 hours. After the reaction is completed, the system is heated up to 150°C, and all solvents in the system are removed by distillation under reduced pressure. After the distillation, an appropriate amount of diatomaceous earth is added to help The filter press is filtered to obtain the finished product of chlorine-free low alkali value calcium sulfonate detergent.

[0028] In this implementation, organic amine refers to the NH-containing 4 + of organic salts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com