Rotary silicon target material capable of being uniformly sputtered and preparation method of rotary silicon target material

A silicon target and sputtering technology, which is applied in the field of uniform sputtering rotating silicon target and its preparation, can solve the problems of reducing the utilization rate and service life of the target, grooves at both ends of the target, and high sputtering rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

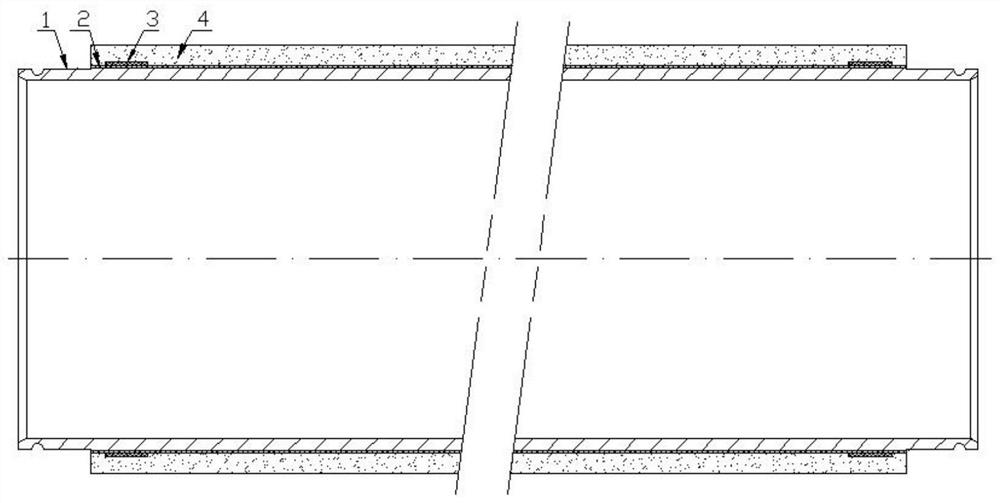

[0035] The present invention provides a method for preparing the above-mentioned rotating silicon target that can be evenly sputtered, comprising the following steps:

[0036] (1) Under a protective atmosphere, arc spray self-adhesive layer material to the surface of the liner to obtain a liner with a self-adhesive layer;

[0037] (2) Under a protective atmosphere, plasma thermal spraying magnetic material powder is applied to both ends of the self-adhesive layer surface in the liner with the self-adhesive layer to form a first magnetic material layer and a second magnetic material layer to obtain a magnetic material having The liner of the material layer;

[0038] (3) Under a protective atmosphere, plasma thermal spraying silicon powder on the outer surface of the liner with the magnetic material layer to form an outer layer of silicon to obtain a rotating silicon target that can be evenly sputtered.

[0039] In the invention, the self-adhesive layer material is arc-sprayed ...

Embodiment 1

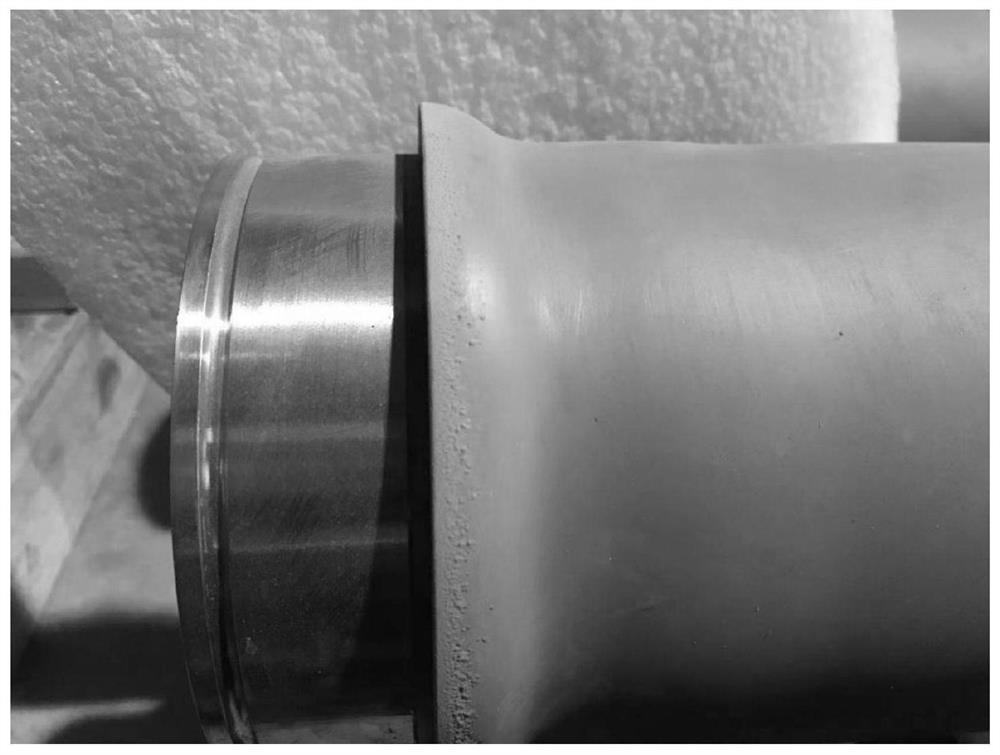

[0057] Preparation specification is OD 2 149 / OD 1 133-ID125*L940 rotating silicon target, target thickness = (OD 2 -OD 1 ) / 2=8mm(where OD 2 is the outer diameter of the silicon target, OD 1 is the outer diameter of the liner, ID is the inner diameter of the liner, and L is the length of the silicon target).

[0058] The preparation method is as follows:

[0059] (1) The liner is machined according to the required size, and cleaned and sandblasted. Ultrasonic cleaning is used for cleaning, and 12# white corundum is used for sandblasting to roughen the surface, with a surface roughness of 89 μm.

[0060] (2) Place the liner in a nitrogen atmosphere protection chamber, use φ2.4mm aluminum-clad nickel composite wire (aluminum accounts for 5wt%), and use atmosphere-protected arc spraying equipment for spraying, and the thickness of the self-adhesive layer is 0.3mm; spraying The main process gas is nitrogen, the nitrogen pressure is 0.6MPa, the voltage is 43V, and the current ...

Embodiment 2

[0070] Preparation specification is OD 2 145 / OD 1 133-ID125*L850 rotating silicon target, target thickness = (OD 2 -OD 1 ) / 2=6mm(where OD 2 is the outer diameter of the silicon target, OD 1 is the outer diameter of the liner, ID is the inner diameter of the liner, and L is the length of the silicon target).

[0071] The preparation method is as follows:

[0072] (1) The liner is machined according to the required size, and cleaned and sandblasted. Ultrasonic cleaning is used for cleaning, and 12# white corundum is used for sandblasting to roughen the surface, and the surface roughness is 118μm.

[0073] (2) Place the liner in a nitrogen atmosphere protection chamber, use φ2mm aluminum-clad nickel composite wire (aluminum accounts for 3wt%), and use atmosphere-protected arc spraying equipment for spraying, and the thickness of the self-adhesive layer is 0.3mm; the main process of spraying The gas is nitrogen, the nitrogen pressure is 0.8MPa, the voltage is 45V, and the cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com