Method for improving water vapor barrier property of food packaging paper under high temperature and high humidity

A water vapor barrier, high temperature and high humidity technology, applied in wrapping paper, wrapping paper, packaging, etc., can solve problems such as low moisture resistance, difficulty in guaranteeing green environmental protection performance, food quality and shelf life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Coating of physically cross-linked polyvinyl alcohol / nanoclay / alkali lignin composite gel (20:1:1) reduces the water vapor transmission rate of paper.

[0022] method:

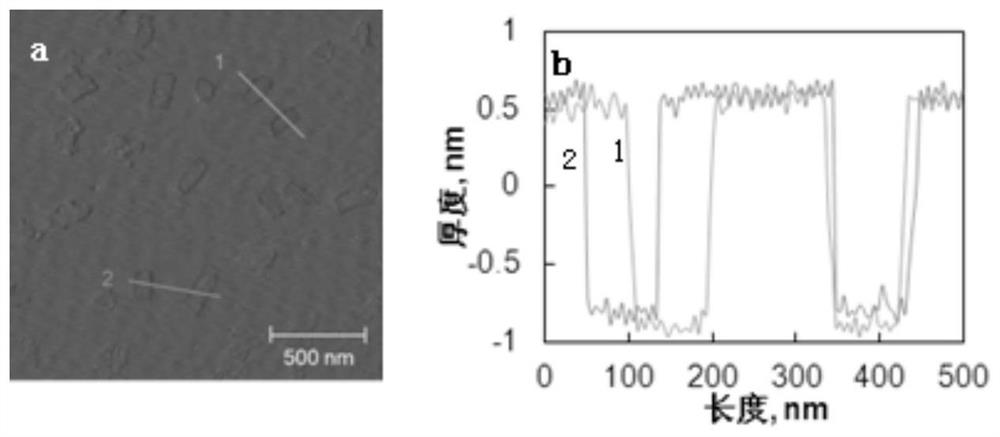

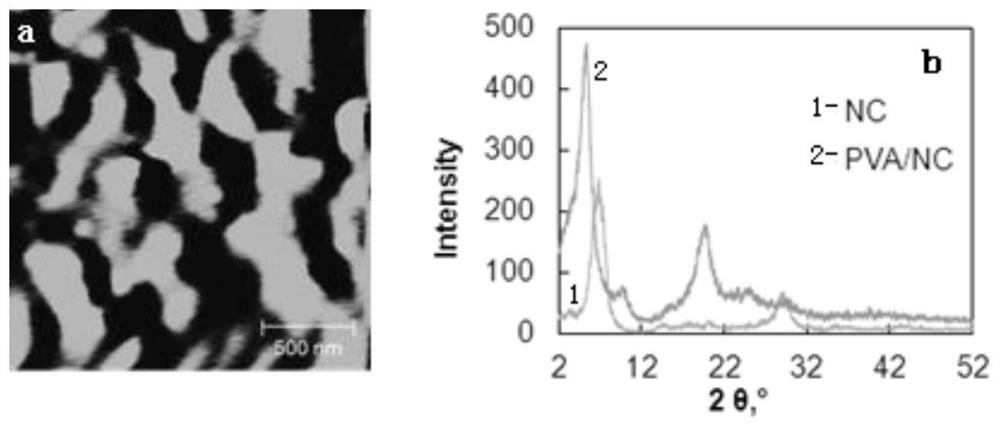

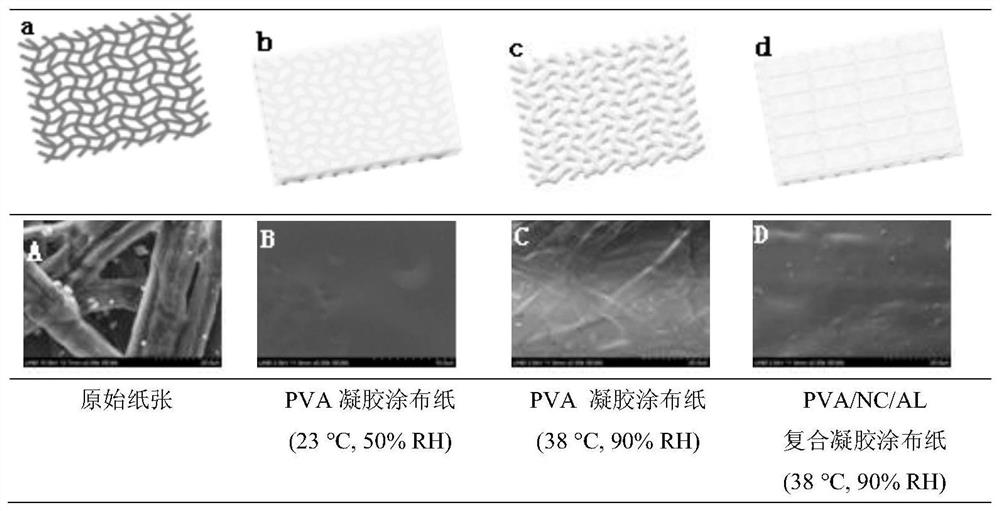

[0023] Mix polyvinyl alcohol, nanoclay and alkali lignin at a volume ratio of 20:1:1 at a volume ratio of 2.0 wt%, and crosslink for 2 hours by adding borax to obtain a composite gel. The composite gel is coated on the surface of paper, and dried under normal pressure to obtain coated paper. According to the TAPPI T448om-09 standard method, the water vapor transmission rate of the paper at 23°C, 50% relative humidity (RH) and 38°C, 90% RH were respectively measured.

[0024] The experimental results are shown in Table 1:

[0025] The water vapor transmission rate of the reference sample at 23°C, 50%RH and 38°C, 90%RH are 512g / m 2 / d and 1861g / m 2 / d. When the PVA / NC / AL composite gel (20:1:1) is coated on the paper surface with an amount of 4g / m 2 , the water vapor transmission rate of c...

Embodiment 2

[0029] Example 2: Coating of physically cross-linked polyvinyl alcohol / nanoclay / alkali lignin composite gel (10:1:1) reduces the water vapor transmission rate of paper.

[0030] method:

[0031] Same as Example 1, the difference is that polyvinyl alcohol, nanoclay and alkali lignin are mixed in a volume ratio of 10:1:1.

[0032] The experimental results are shown in Table 2:

[0033] When the PVA / NC / AL composite gel (10:1:1) is coated on the paper surface with an amount of 4g / m 2 , the water vapor transmission rate of the coated paper at 23°C, 50%RH and 38°C, 90%RH is respectively reduced to 5g / m 2 / d and 132g / m 2 / d.

[0034] Table 2 Composite gel (10:1:1) coated paper water vapor transmission rate (WVTR, g / m 2 / d)

[0035]

[0036] By adjusting the volume ratio of each component of the composite gel, the water vapor transmission rate of the paper can be effectively improved. When the volume ratio of polyvinyl alcohol, nanoclay and alkali lignin in the composite gel ...

Embodiment 3

[0037] Example 3: Coating of physically cross-linked polyvinyl alcohol / nanoclay / alkali lignin composite gel (5:1:1) reduces the water vapor transmission rate of paper.

[0038] method:

[0039] Same as Example 1, the difference is that polyvinyl alcohol, nanoclay and alkali lignin are mixed in a volume ratio of 5:1:1.

[0040] The experimental results are shown in Table 3:

[0041] When the PVA / NC / AL composite gel (5:1:1) is coated on the paper surface with an amount of 4g / m 2 , the water vapor transmission rate of coated paper at 23°C, 50%RH and 38°C, 90%RH is respectively reduced to 21g / m 2 / d and 218g / m 2 / d.

[0042] Table 3 Composite gel (5:1:1) coated paper water vapor transmission rate (WVTR, g / m 2 / d)

[0043]

[0044] Continue to increase the volume ratio of nanoclay and alkali lignin in the composite gel, that is, the volume ratio of polyvinyl alcohol, nanoclay and alkali lignin is adjusted to 5:1:1, and the coating amount is 4g / m 2 At 23°C, 50% RH and 38°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com