Staged invisible closed automatic road drainer

A staged, drainer technology, applied in drainage structures, waterway systems, water supply devices, etc., can solve problems such as poor drainage, affecting vision, and small drainage area, and achieve the effect of facilitating drainage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

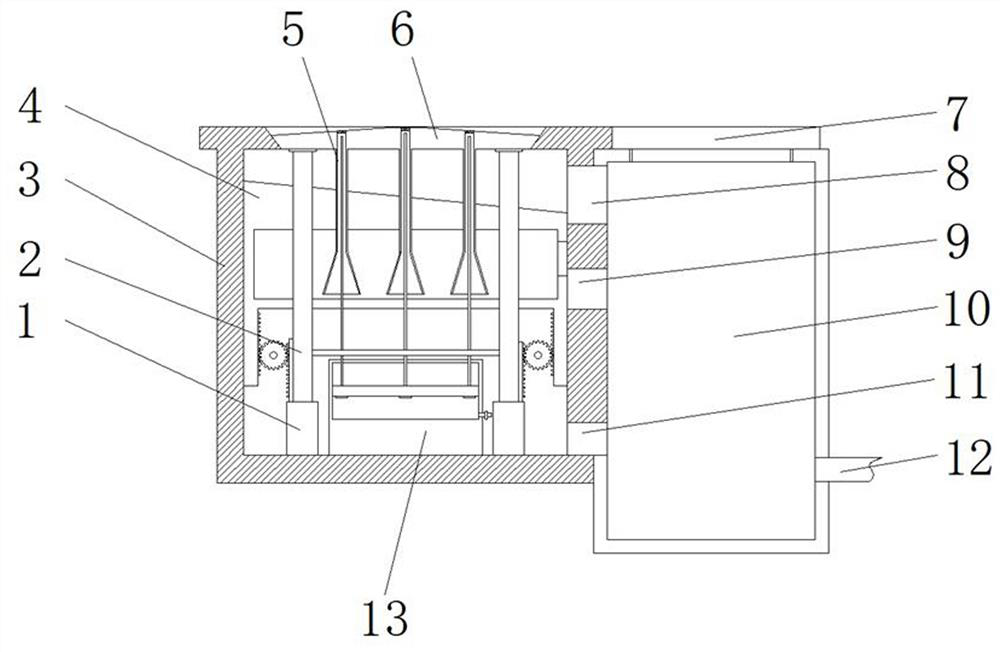

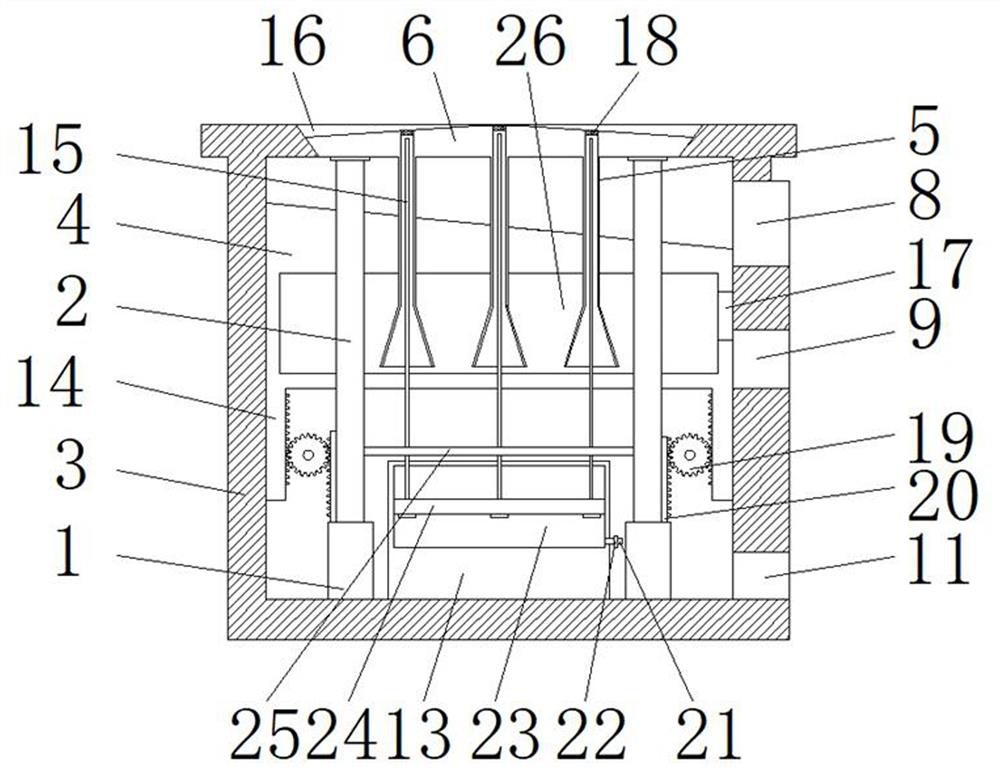

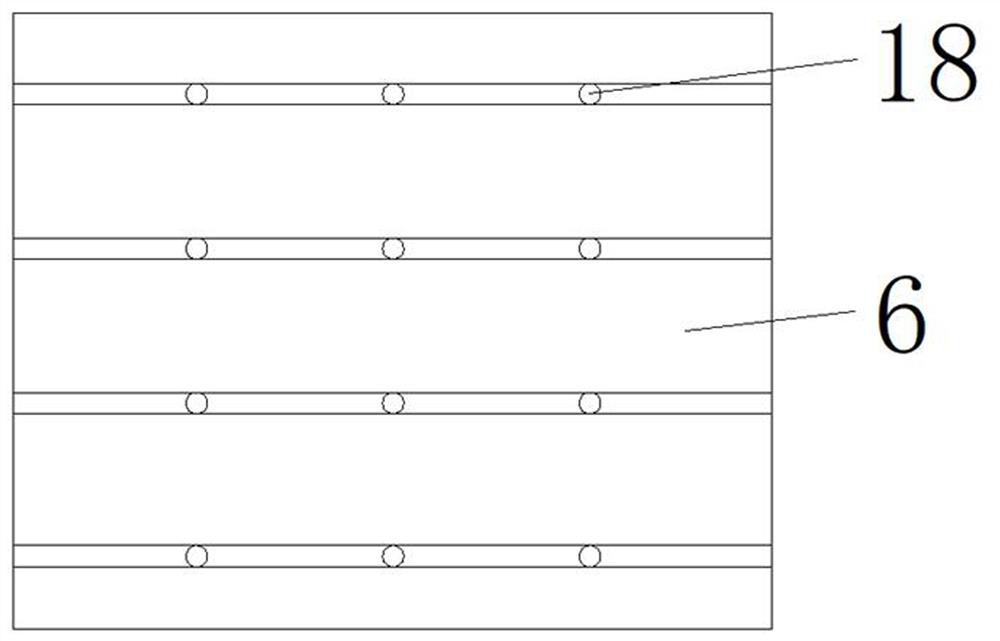

[0024] Such as Figure 1-3 A staged invisible airtight automatic road drainer shown includes a drainage cavity 3, the top of the drainage cavity 3 is provided with a water inlet groove 16 whose inner diameter is inclined from the outside to the inside, and the top of the drainage chamber 3 is covered with a water inlet groove 16. The matching cover body 6 has a water inlet 18 evenly opened on the cover body 6, and the bottom of the cover body 6 at the position of the water inlet 18 is connected with a water inlet pipe 5, and both sides of the bottom of the cover body 6 are fixed with support rods 2 for drainage. The inside of the cavity 3 is slidably connected with a sliding seat 4, and the inside of the sliding seat 4 is provided with a water storage tank 26, and the middle position on one side of the water storage tank 26 is provided with an overflow port 17, and the two sides of the bottom of the sliding seat 4 are fixed with mutually symmetrical The first rack 14, the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com