Diffuser with self-adaptive curvature profile in semi-vaneless area

A diffuser, self-adaptive technology, applied in the direction of machines/engines, components of pumping devices for elastic fluids, coatings, etc., can solve the problem of affecting the stability of radial diffusers and centrifugal impellers to match diffusers Range, non-uniform velocity, degraded radial diffuser performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

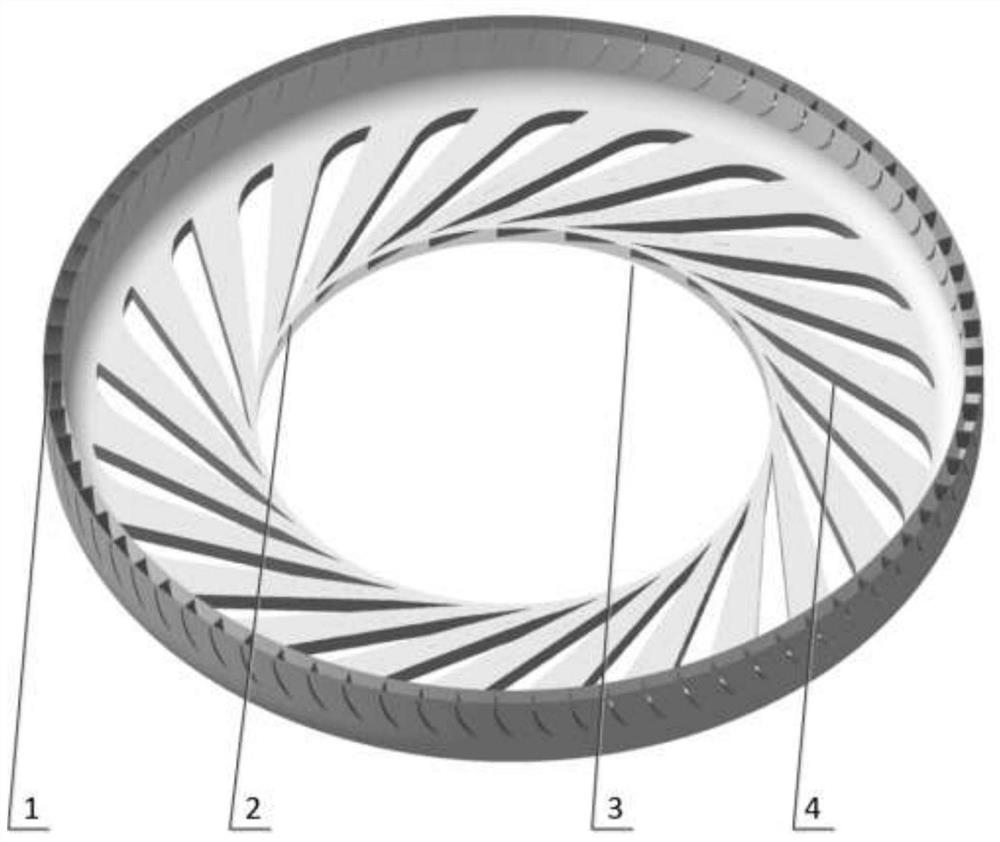

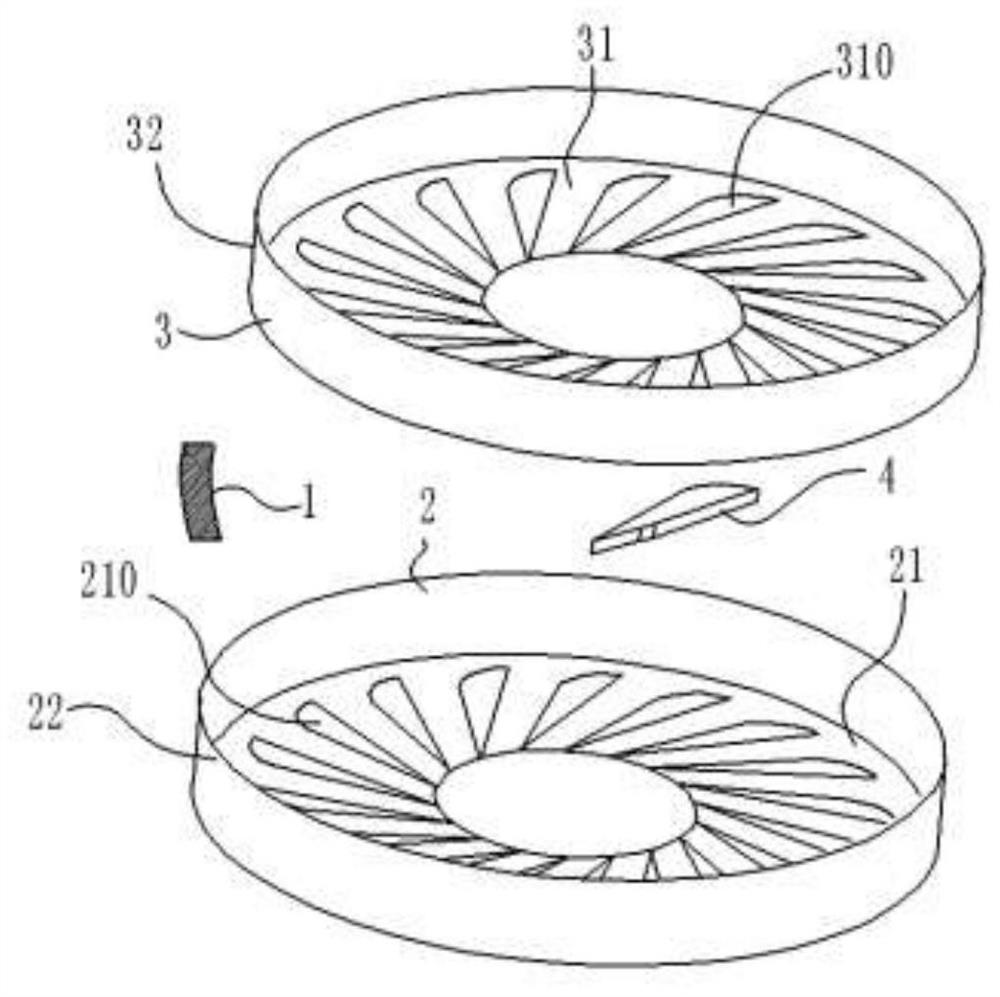

[0038] Embodiment 1: as figure 2 The shown diffuser has a self-adaptive curvature profile in the semi-bladeless area, including the upper and lower diffuser cover 3, the diffuser disc 2, and the diffuser cover respectively 3. Axial diffuser blades 1 and radial diffuser blades 4 between the diffuser discs 2;

[0039] Such as figure 2 As shown, the diffuser disc 2 includes an annular disc 21 uniformly provided with first through holes 210 in the circumferential direction, and a disc barrel 22 arranged on the annular disc 21;

[0040] The diffuser wheel cover 3 includes an annular wheel cover 31 uniformly provided with second through holes 310 in the circumferential direction, and a wheel cover tube 32 arranged on the annular wheel cover 31;

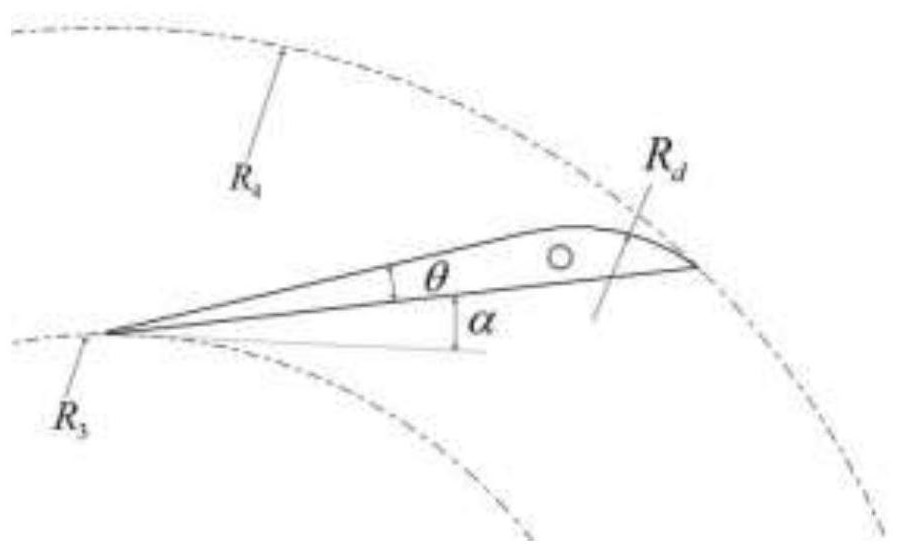

[0041] The number of the first through hole 210, the second through hole 310 and the radial diffuser blade 4 are equal and the positions between the first through hole 210 and the second through hole 310 are corresponding, and the radia...

Embodiment 2

[0053] Embodiment 2: Different from Embodiment 1: as Image 6 As shown, the radial diffuser blade 4 includes a first baffle blade 41 and a second baffle blade 42 whose head and tail ends are connected to each other; it can be prepared simultaneously with the wheel disc and the wheel cover to realize the integrated preparation of the diffuser; wherein, the diffuser The integrated preparation method of the compressor is as follows: firstly model the radial diffuser blade 4 according to the above-mentioned modeling method, and determine the modeling structure of the second baffle blade 42; then use UG 3D software to create a 3D model of the diffuser, The diffuser is then integrated with a 3D printing device to obtain a diffuser base; and then the diffuser base is sintered to obtain a diffuser.

experiment example

[0054] Experimental example: The expander of Example 1 of the present invention and the traditional expander were applied to different compressors for performance comparison. Such as Figure 7 , 8 As shown in the preliminary performance comparison, it is found that the adaptive curvature diffuser can improve the stage pressure ratio and peak efficiency of the original compressor by 0.041 and 1.8% on the basis of ensuring that the static pressure recovery coefficient is not lower than that of the original wedge diffuser, At the same time, it has a wider margin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com