High-efficiency air supply and return engineering construction method for low-stable-speed and auxiliary-flow clean air conditioner

A clean air-conditioning and high-efficiency technology, which is applied in the construction method of return air engineering, high-efficiency delivery of auxiliary flow clean air-conditioning, and low and stable speed fields, which can solve the high cost of one-way flow clean room and the difficulty of construction and maintenance of one-way flow clean room. major problems, to achieve the effect of reasonable construction process design, low construction cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

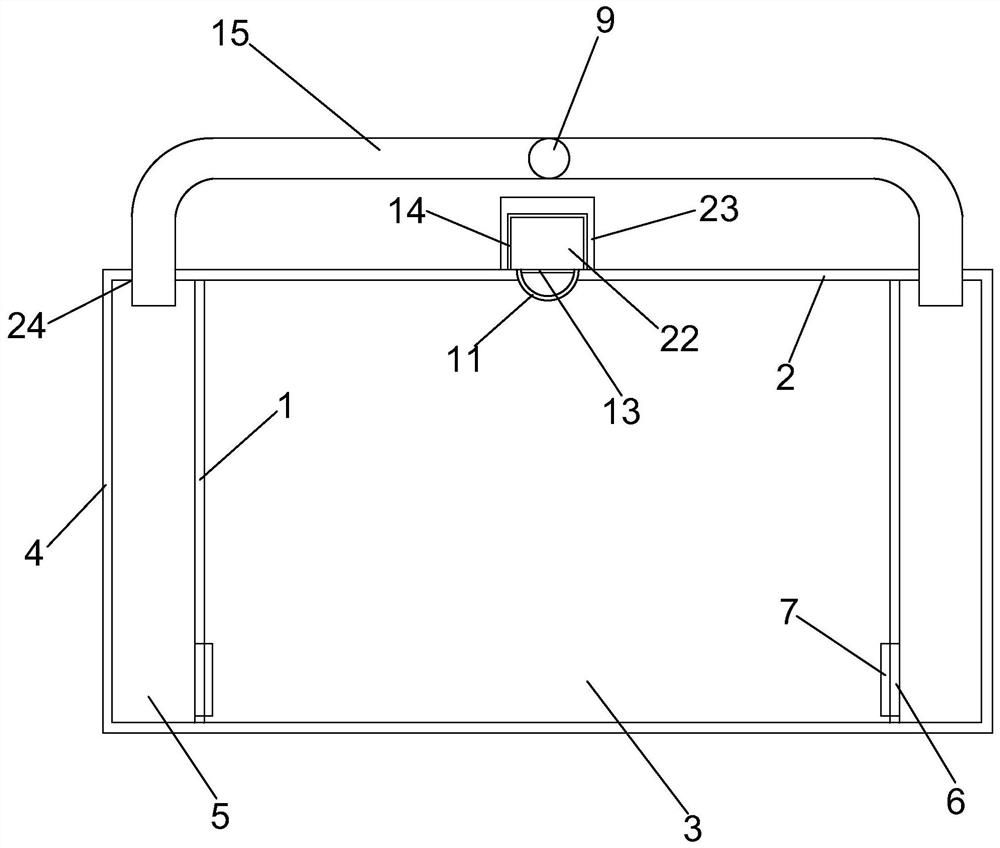

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

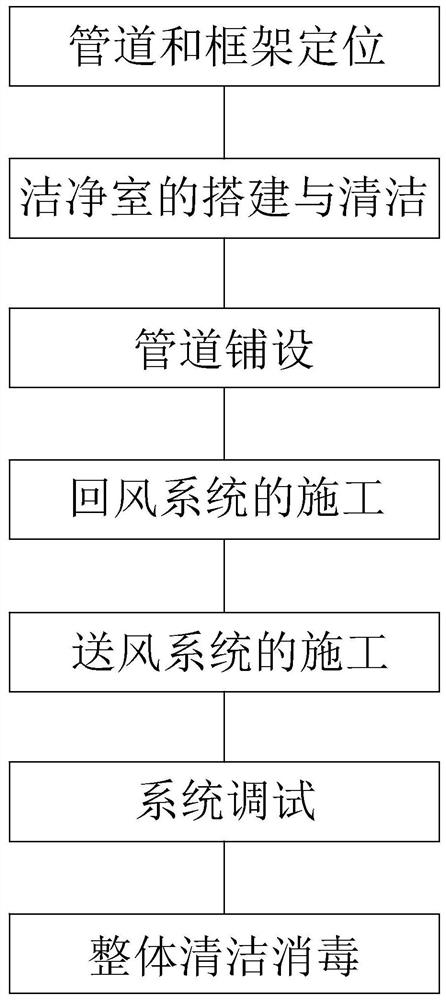

[0028] Figure 1-5 The construction method of a low-steady-speed, auxiliary-flow clean air-conditioning high-efficiency air supply and return engineering construction method is characterized in that it includes the following steps:

[0029] Step 1. Pipeline and frame positioning: use relevant instruments to measure and locate the installation site of the pipeline and system frame to be installed;

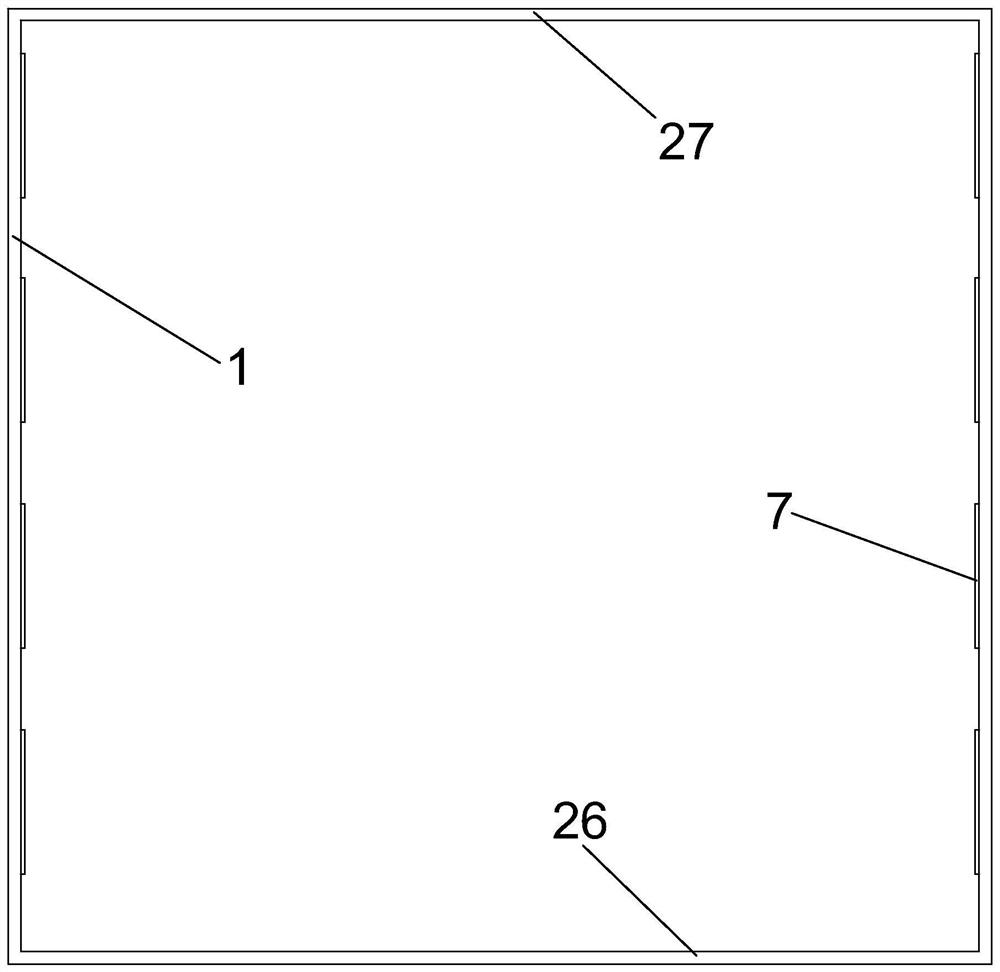

[0030] Step 2. Construction and cleaning of the clean room: Lay the clean room floor, which is composed of composite PVC board, rubber board, epoxy self-leveling floor or ceramic tiles, build the clean room side panel 1, the clean room front panel 25, and the clean room rear panel 26 And clean room top plate 2, clean room side plate 1, clean room front plate 25, clean room rear plate 26 and clean room top plate 2 are composed of composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com