High-flexibility signal composite cable for high-end medical equipment and method

A kind of technology of medical equipment, composite cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

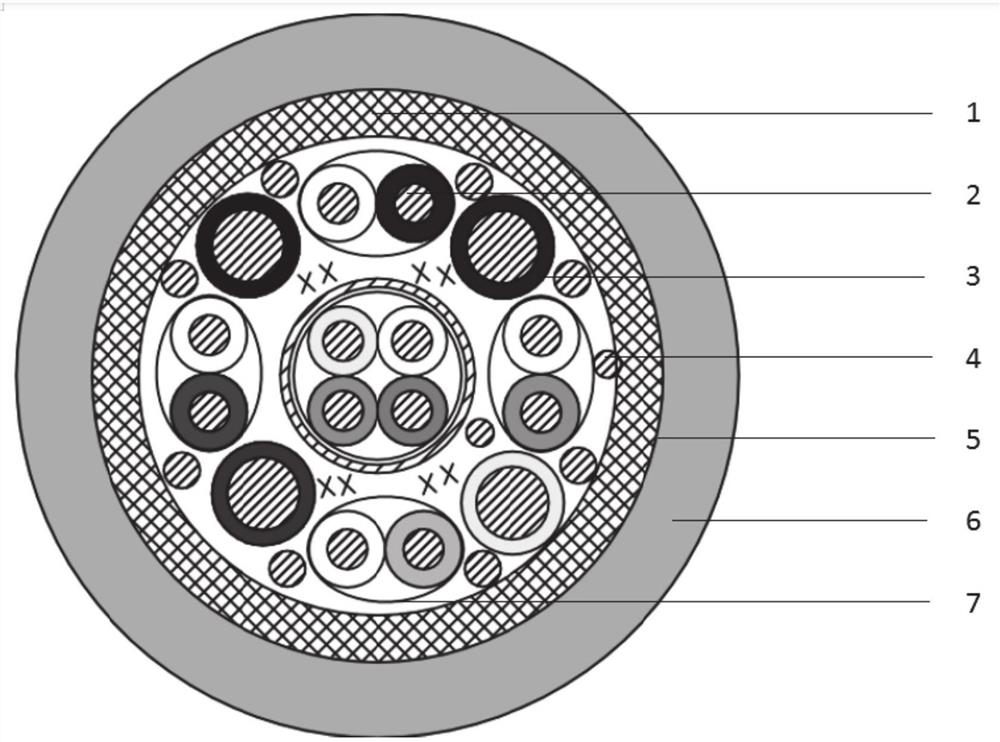

[0026] Such as figure 1 As shown, the present disclosure provides a high-flexibility signal composite cable for high-end medical equipment, including a transmission line group, a braided shielding layer, a sheath, and a non-woven fabric arranged sequentially from the inside to the outside, and the transmission line group includes several different types of The transmission line is filled with bulletproof wire.

[0027] Further, bulletproof wires are filled between the transmission lines and the junction area between the transmission lines and the braided shielding layer, Kevlar bulletproof wires are used to increase the tensile performance, and the bulletproof wires can effectively reduce wear and tear, improve the tensile strength and Bending resistance.

[0028] Further, the gaps between the transmission lines are filled with bulletproof wires.

[0029] Further, different types of transmission lines are arranged alternately, and distributed in a ring in the braided shieldi...

Embodiment 2

[0041] The present disclosure also provides a production method of a high-flexibility signal composite cable for high-end medical equipment, including the following steps:

[0042] The conductor of the transmission line adopts copper tinned copper conductor structure;

[0043] Conductor insulation adopts high-density polyethylene insulation to form an insulated core;

[0044]The insulated wire cores are grouped and twisted according to actual needs, wrapped with light non-woven fabric, and then twisted into cables, and the cable gaps are filled with Kevlar bulletproof wire.

[0045] Specifically, a. The conductors are all made of 0.05mm ultra-fine copper tinned copper conductor structure.

[0046] b. The insulation of the conductor is insulated with high-density polyethylene to form an insulated core.

[0047] c. Insulated wire cores are grouped and twisted according to actual needs, wrapped with light non-woven fabric, and each unit is twisted into a cable, and the cable ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com