Steel sheet and manufacturing method therefor

A steel plate and residual technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of stamping cracks, ductility decrease, stretch flange formability decrease, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0234] Cold-rolled steel sheets with a thickness of 1.2 mm having the compositions shown in Table 1 were treated under the annealing conditions shown in Table 2-1 to manufacture steel sheets of the present invention and steel sheets of comparative examples.

[0235]In addition, some steel sheets (cold-rolled steel sheets) were further subjected to a hot-dip galvanizing treatment to obtain hot-dip galvanized steel sheets (GI). Here, the steel sheet is immersed in a zinc coating bath of 440° C. to 500° C. to perform hot-dip galvanizing treatment, and then, the amount of plating deposition is adjusted by gas wiping or the like. For the molten zinc plating, a zinc plating bath having an Al content of 0.10% or more and 0.22% or less is used. In addition, after the hot-dip galvanizing treatment, a part of the hot-dip galvanized steel sheet is subjected to an alloying treatment of galvanizing to obtain an alloyed hot-dip galvanized steel sheet (GA). Here, the alloying treatment of t...

Embodiment 2

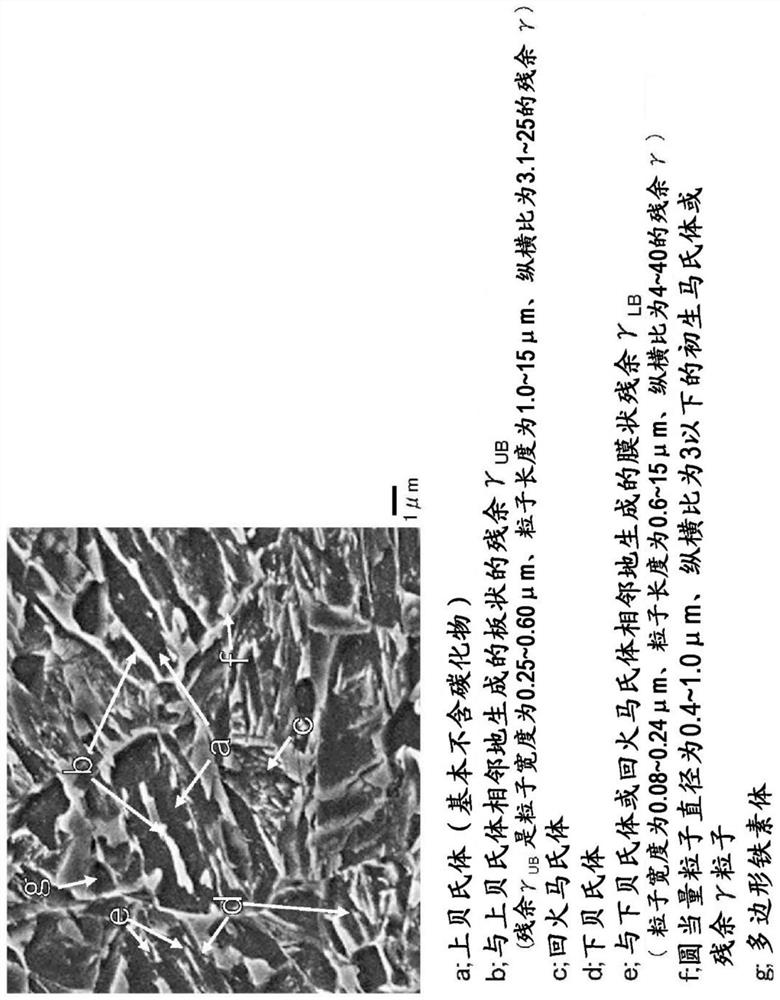

[0250] A cold-rolled steel sheet with a thickness of 1.2 mm having the composition shown in Table 1 was treated under the annealing conditions shown in Table 3-1 to manufacture the steel sheet of the present invention and the steel sheet of the comparative example. The measurement of the steel structure and the evaluation of the mechanical properties of the obtained steel sheets were performed by the same method as above, and the results are shown in Table 3-2. It should be noted that the plate-shaped residual γ formed adjacent to the upper bainite UB The area ratio of S γUB Come and find out.

[0251] In the examples of the present invention of No.1, 2, 3, and 7, the excellent uniform elongation (ductility) of 9% or more is satisfied under the condition of TS: 780-1319MPa level, and (TS×U.El-7000 )×λ≧260000MPa%, pore expandability (λ) of 30% or more, under the condition of TS: 1320MPa level or more, satisfying the excellent uniform elongation (ductility) of 8% or more, sati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com