Instant noodles obtained by kneading dough with fresh eggs, and preparation method of instant noodles

A technology for fresh eggs and instant noodles, which is applied to the field of instant noodles with fresh eggs and noodles and their preparation, can solve problems such as loss of noodle taste, gluten network damage, deviation from the ultimate goal of noodles, etc., and achieves increasing the content of nutrients such as phospholipids and reducing the content of oil and fat. , the effect of solving nutritional problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The invention provides a method for preparing instant noodles made of fresh eggs and noodles, comprising:

[0053] A) Egg white liquid and egg yolk liquid are subjected to ultrasonic and homogeneous emulsification treatment respectively to obtain pretreated egg white liquid and pretreated egg yolk liquid respectively;

[0054] B) mixing the pretreated egg white liquid, egg yolk liquid, edible salt, thickener, phosphate and water, and stirring to obtain a water-mixing material liquid;

[0055] C) Flour, tapioca starch, acetate starch, and gluten are placed in a dough mixer, mixed with a water preparation liquid, and dough is mixed and matured to obtain a matured dough;

[0056] D) Composite calendering, continuous calendering and shredding of the matured dough to obtain noodles;

[0057] E) atomizing and spraying the pretreated egg yolk liquid on the surface of the noodles and steaming the noodles to obtain steamed noodles;

[0058] F) The steamed noodles are obtained ...

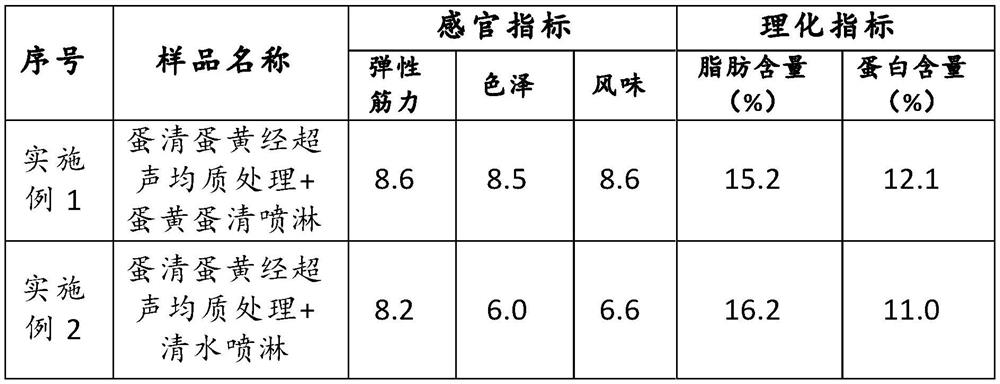

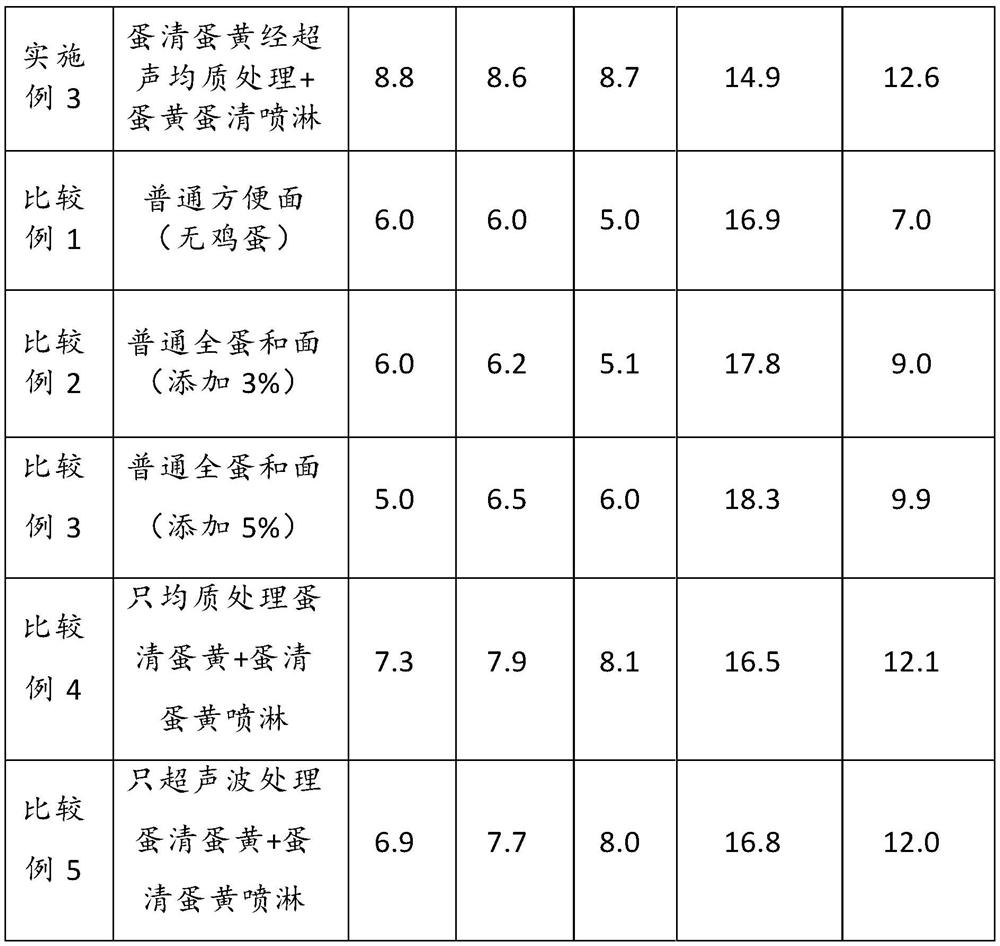

Embodiment 1

[0092] The preparation method of the instant noodles of present embodiment fresh egg and face comprises the following steps:

[0093] 1. The batching components are: 100 parts by weight of flour (containing 16% Australian wheat flour), 16 parts by weight of tapioca starch, 13 parts by weight of acetate starch, 2 parts by weight of gluten powder, 6 parts by weight of egg white liquid, and 3 parts by weight of egg yolk liquid, 0.2 parts by weight thickener, 1.6 parts by weight of edible salt, 0.11 parts by weight of phosphate, 34 parts by weight of water;

[0094] 2. Pretreatment of egg white and egg yolk: separate egg white and egg yolk, and use ultrasonic homogenization and emulsification to process egg white and egg yolk. The ultrasonic power for egg yolk liquid treatment is 450W, and the time is 5 minutes; the homogenization working pressure is 15-20Mpa, and the homogenization time is 6 minutes; The time is 8 minutes; standby

[0095] 3. Water distribution material liquid ...

Embodiment 2

[0101] The preparation method of the instant noodles of present embodiment fresh egg and face comprises the following steps:

[0102] 1. The batching components are: 100 parts by weight of flour (containing 16% Australian wheat flour), 16 parts by weight of tapioca starch, 13 parts by weight of acetate starch, 2 parts by weight of gluten powder, 6 parts by weight of egg white liquid, and 3 parts by weight of egg yolk liquid, 0.2 parts by weight thickener, 1.6 parts by weight of edible salt, 0.11 parts by weight of phosphate, 34 parts by weight of water;

[0103] 2. Pretreatment of egg white and egg yolk: separate egg white and egg yolk, and use ultrasonic homogenization and emulsification to process egg white and egg yolk. The ultrasonic power for egg yolk liquid treatment is 450W, and the time is 5 minutes; the homogenization working pressure is 15-20Mpa, and the homogenization time is 6 minutes; The time is 8 minutes; standby

[0104] 3. Water distribution material liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com