Ready-to-eat bean jelly not easy to age and preparation method thereof

A jelly, not easy technology, applied in the field of non-aging instant jelly and its preparation, can solve the problem of jelly texture becoming hard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, the ingredients of the non-aging instant jelly are 85kg of drinking purified water, 14kg of mung bean starch, 1kg of anti-aging agent (0.6kg of hydroxypropyl distarch phosphate, 0.3kg of β-cyclodextrin, 0.3kg of mono- and diglyceride fat Ester 0.06kg, carrageenan 0.04kg), its preparation method is as follows:

[0023] (1) pulping

[0024] Take 14kg of mung bean starch, add 14kg of drinking purified water, and stir evenly;

[0025] (2) Anti-aging agent solution preparation

[0026] Mix 0.6kg of hydroxypropyl distarch phosphate, 0.3kg of β-cyclodextrin, 0.06kg of monoglyceride fatty acid ester, and 0.04kg of carrageenan, then pour it into 71kg of drinking purified water at 65°C, and stir thoroughly dissolve;

[0027] (3) starch gelatinization

[0028] Pour the starch paste into the anti-aging agent solution under stirring, and heat until the starch paste is transparent;

[0029] (4) Filling and vacuum sealing

[0030] Put the starch paste into th...

Embodiment 2

[0034] In the present embodiment, the ingredients of the non-aging instant jelly are 86.3kg of drinking purified water, 7kg of broad bean starch, 6kg of white kidney bean starch, 0.7kg of anti-aging agent (0.39kg of hydroxypropyl distarch phosphate, β-cyclodextrin 0.24kg, mono-diglyceride fatty acid ester 0.04kg, carrageenan 0.03kg), its preparation method is as follows:

[0035] (1) pulping

[0036] Get 7kg of broad bean starch and 6kg of white kidney bean starch, add 19.5kg of drinking purified water, and stir evenly;

[0037] (2) Anti-aging agent solution preparation

[0038] After mixing 0.39kg of hydroxypropyl distarch phosphate, 0.24kg of β-cyclodextrin, 0.04kg of monoglyceride fatty acid esters, and 0.03kg of carrageenan, pour it into 66.8kg of drinking purified water at 70°C, fully Stir to dissolve;

[0039] (3) starch gelatinization

[0040] Pour the starch paste into the anti-aging agent solution under stirring, and heat until the starch paste is transparent;

...

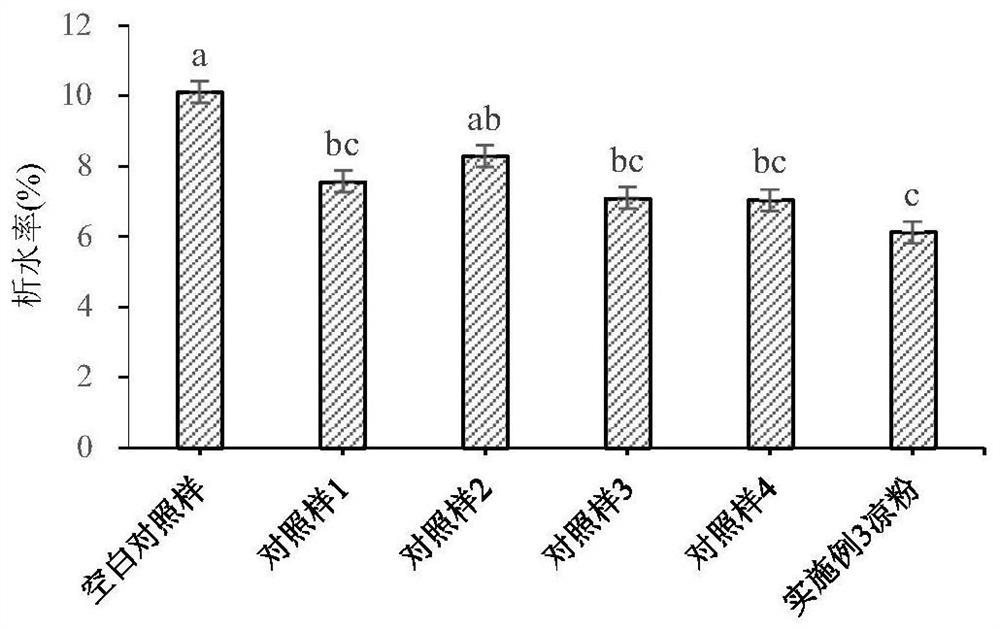

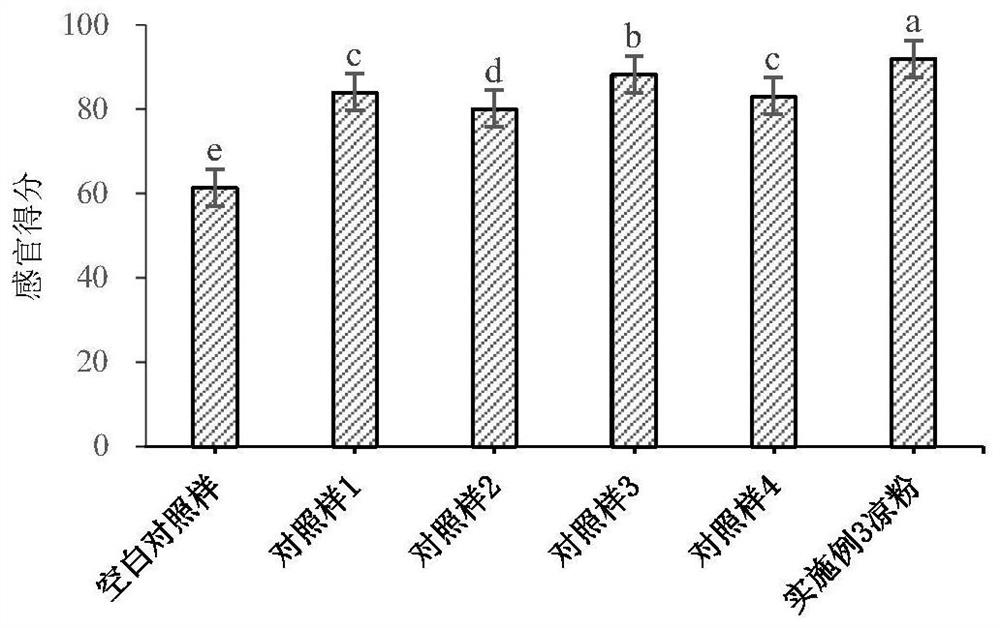

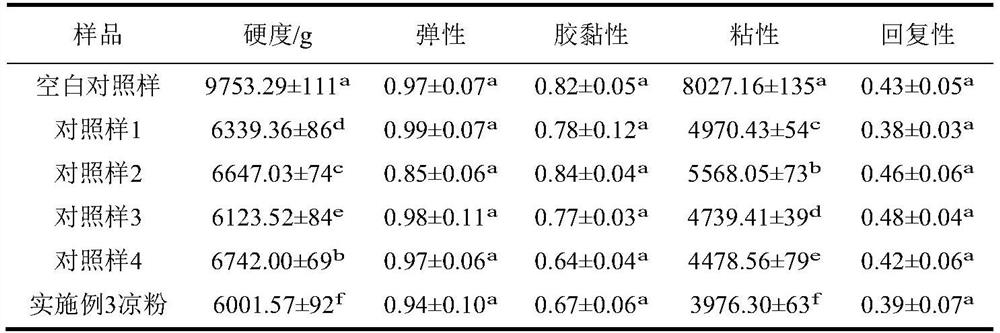

Embodiment 3

[0046] In this embodiment, the ingredients of the non-aging instant jelly are 87.6kg of drinking purified water, 12kg of pea starch, 0.4kg of anti-aging agent (0.2kg of hydroxypropyl distarch phosphate, 0.16kg of β-cyclodextrin, single and double Glycerin fatty acid ester 0.02kg, carrageenan 0.02kg), its preparation method is as follows:

[0047] (1) pulping

[0048] Take 12kg of pea starch, add 24kg of drinking purified water, and stir evenly;

[0049] (2) Anti-aging agent solution preparation

[0050] After mixing 0.2kg of hydroxypropyl distarch phosphate, 0.16kg of β-cyclodextrin, 0.02kg of mono- and diglyceride fatty acid esters, and 0.02kg of carrageenan, pour 63.6kg of drinking purified water at 75°C, fully Stir to dissolve;

[0051] (3) starch gelatinization

[0052] Pour the starch paste into the anti-aging agent solution under stirring, and heat until the starch paste is transparent;

[0053] (4) Filling and vacuum sealing

[0054] Put the starch paste into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com