Medical heat pipe drill bit for cortical bone processing, and use method of medical heat pipe drill bit

A cortical bone and drill technology, used in bone drill guidance, medical science, surgery, etc., can solve the problems of high temperature in the cutting part of the tool, environmental pollution, human bone damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

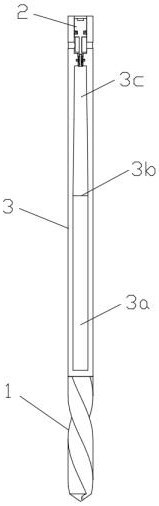

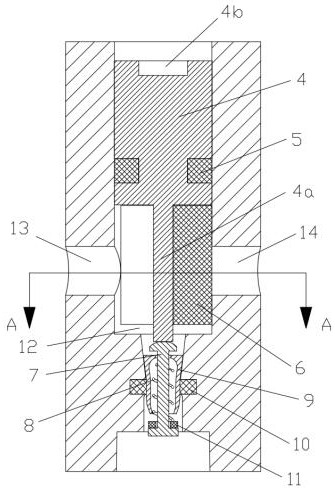

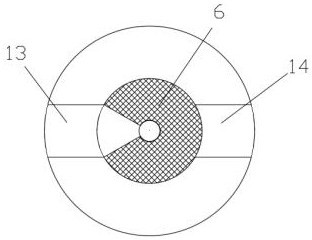

[0035] like Figure 1-2As shown, a medical heat pipe drill for cortical bone processing mainly includes: a drill section 1 , an airtight device 2 , and a heat pipe heat exchange section 3 . The heat exchange section 3 of the heat pipe is located at the root of the drill bit, the part near the front end of the drill bit is the evaporating section 3a of the heat pipe, the part near the top of the shank of the drill bit is the condensing section 3c of the heat pipe, and the part between the evaporating section 3a and the condensing section 3c is the evaporating section 3a of the heat pipe. Insulation section 3b. The rear end of the cortical bone processing drill bit is provided with an axial airtight device mounting hole 12, and the rear end of the cortical bone processing drill bit is also provided with a negative pressure air extraction hole 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com