Hand buckling type sprayer with inclined piston cavity

A technology of piston cavity and handle, which is applied to spray devices, single handheld devices, etc., can solve the problems of poor structural design, troublesome dismantling of metal parts, and easy embrittlement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

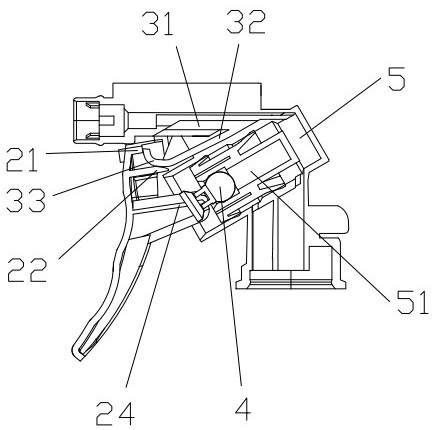

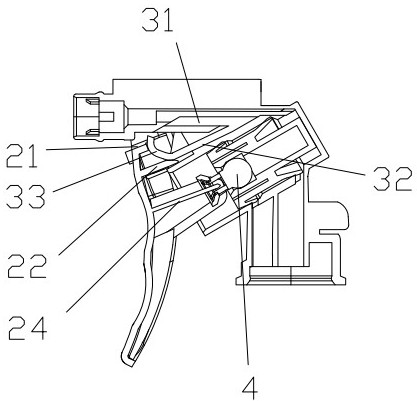

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

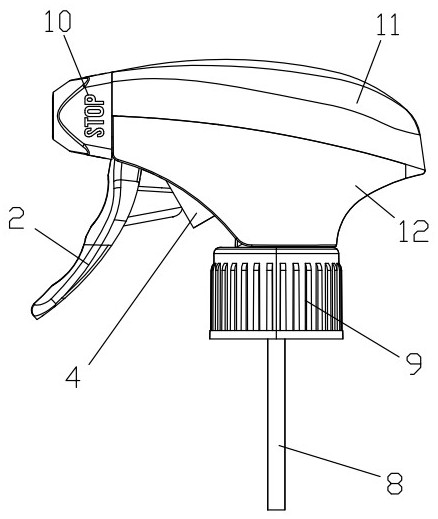

[0036] A sprayer with an oblique piston cavity and a clasp, which consists of a main body, a large cap connected to the bottle body, a straw, a water inlet check valve, a piston chamber, a diversion channel, a water outlet check valve, an atomizing nozzle, and a head cap. The piston in the piston chamber is connected to the trigger, and the shaft of the handle is set under the outlet check valve. The diversion channel is divided into a vertical liquid inlet channel and a horizontal horizontal liquid outlet channel. The liquid inlet channel includes a suction pipe and an inlet valve. The water one-way valve leads to the piston chamber, and the liquid outlet channel passes through the water outlet one-way valve from the outlet of the piston chamber to the head cap.

[0037] Wherein the inclination angle of the piston chamber is 30 degrees to 60 degrees, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com