Waterproof, breathable, machine-washable and down-proof composite fabric and preparation method thereof

A composite fabric, waterproof and breathable technology, applied in chemical instruments and methods, protective clothing, synthetic resin layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In order to solve the above problems, one or more embodiments of this specification provide a method for preparing a waterproof, breathable, machine washable anti-drilling fleece composite fabric, including:

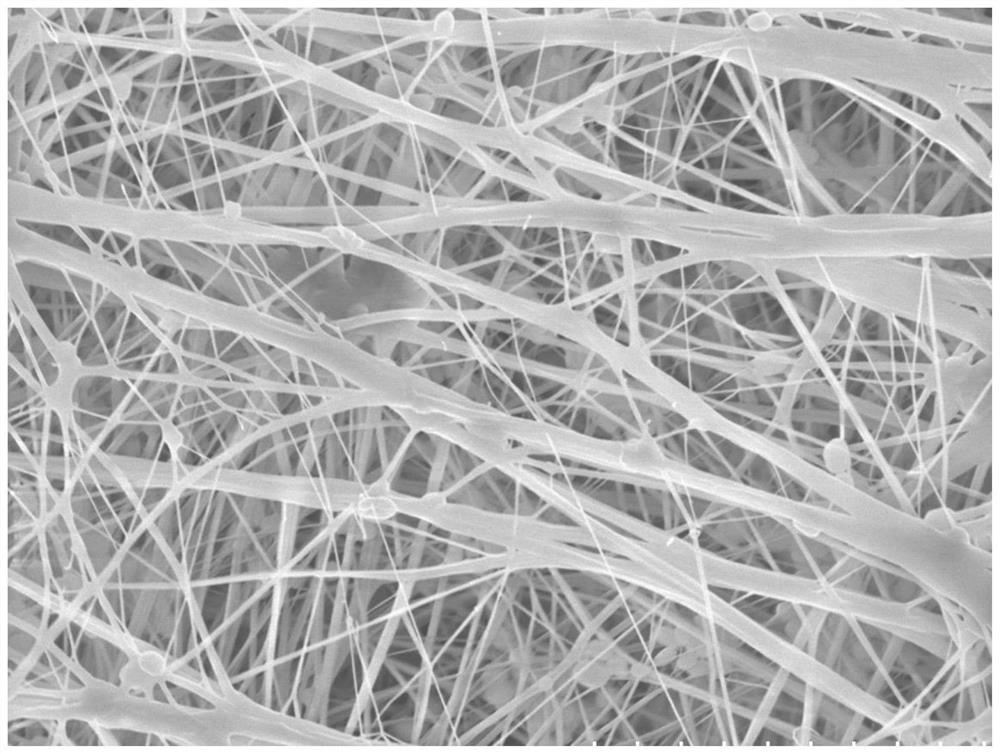

[0036] For the preparation of fiber membranes, add polylactic acid to a mixed solvent of chloroform and acetone, stir and mix evenly to form a polylactic acid solution, and electrospin the polylactic acid solution at a voltage of 10-18kV and a spinning speed of 15-30ml / h Silk, to prepare micro-nano electrospun polylactic acid fiber membrane;

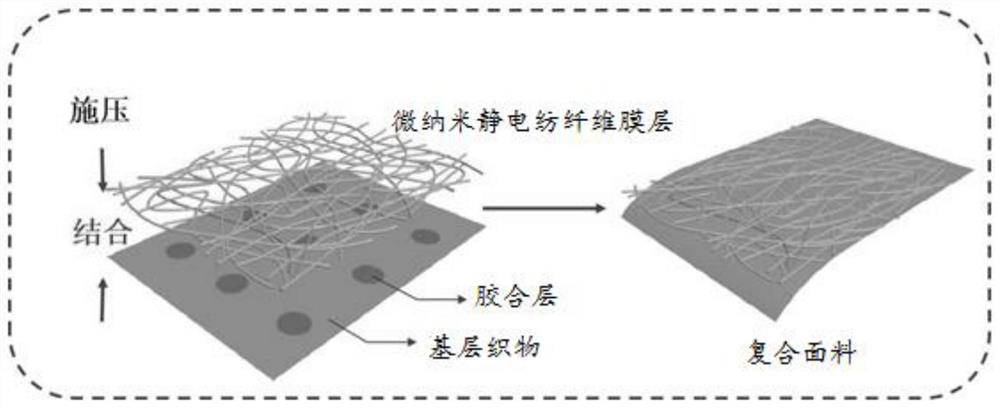

[0037] For the preparation of the composite fabric, the base fabric is taken, the surface of the base fabric is sprayed with glue, and then the micro-nano electrospun polylactic acid fiber film is laminated with the base fabric to obtain a composite fabric.

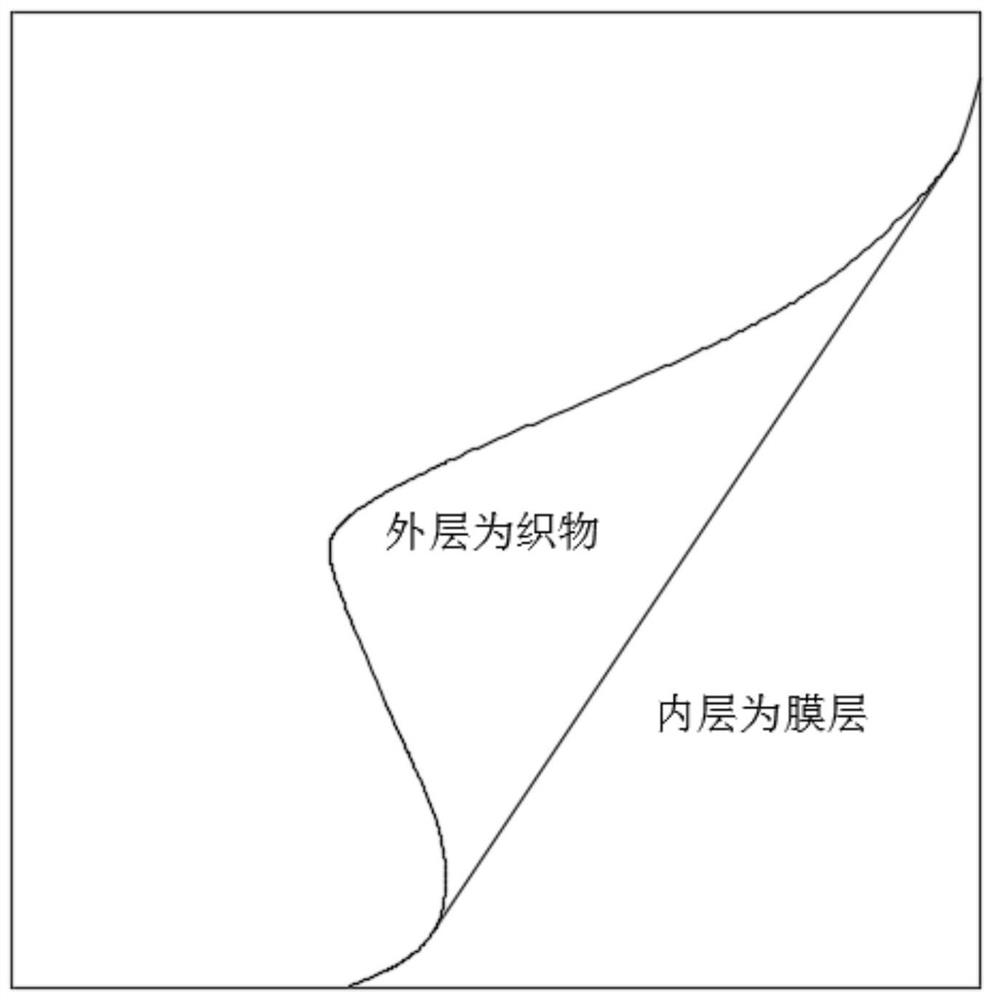

[0038] At the same time, one or more embodiments of this specification also provide a composite fabric prepared by the preparation method of the waterproof, breathable,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com