Environment-friendly high-strength plastic building template and preparation method thereof

A building formwork, high-strength technology, which is applied in the on-site preparation of building components, construction, building construction, etc., can solve problems such as poor environmental protection performance, toxic smoke, and poor performance stability, and achieve comprehensive performance and performance. Good stability, improved mechanical properties and flame retardancy, good overall performance and performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

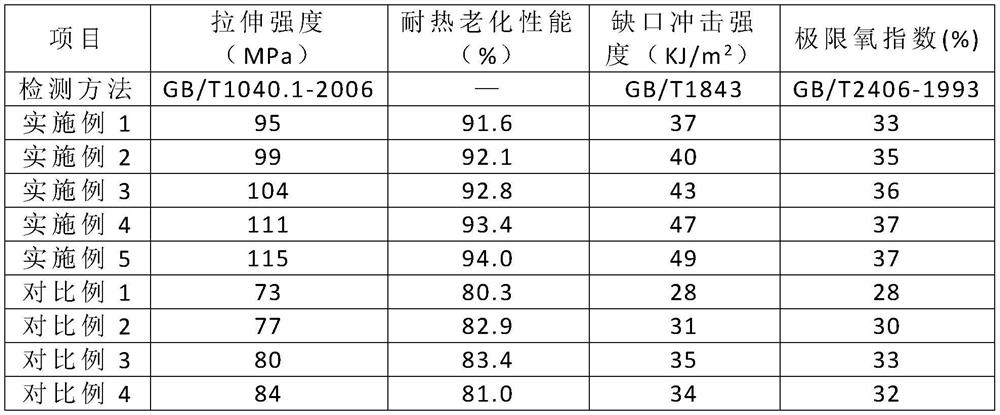

Examples

Embodiment 1

[0032]A method for preparing an environmentally friendly high-strength plastic building formwork, characterized in that it comprises the following steps:

[0033] Step S1, dicarboxyl-modified 4-fluorophenylboronic acid methyliminodiacetate: adding 4-fluorophenylboronic acid methyliminodiacetate and chloromalonic acid to an organic solvent, at 40 The reaction was stirred at ℃ for 6 hours, and then the solvent was removed by rotary evaporation to obtain dicarboxyl-modified 4-fluorophenylboronic acid methyliminodiacetate;

[0034] Step S2, preparation of polycondensate: the dicarboxy-modified 4-fluorophenylboronic acid methyliminodiacetate, 2,4-diamino-6-diallylamino-1, 3,5-triazine, polymerization inhibitor and catalyst are added to the high boiling point solvent, after stirring evenly, the reaction solution is obtained, then the reaction solution is transferred to the high-pressure reactor, and the air in the reactor is replaced with an inert gas, and then the reaction solution...

Embodiment 2

[0043] A method for preparing an environmentally friendly high-strength plastic building formwork, characterized in that it comprises the following steps:

[0044] Step S1, dicarboxyl-modified 4-fluorophenylboronic acid methyliminodiacetate: add 4-fluorophenylboronic acid methyliminodiacetate and chloromalonic acid to an organic solvent at 45 The reaction was stirred at ℃ for 6.5 hours, and then the solvent was removed by rotary evaporation to obtain dicarboxyl-modified 4-fluorophenylboronic acid methyl imino diacetate;

[0045] Step S2, preparation of polycondensate: the dicarboxy-modified 4-fluorophenylboronic acid methyliminodiacetate, 2,4-diamino-6-diallylamino-1, 3,5-triazine, polymerization inhibitor and catalyst are added to the high boiling point solvent, after stirring evenly, the reaction solution is obtained, then the reaction solution is transferred to the high-pressure reactor, and the air in the reactor is replaced with an inert gas, and then the reaction solutio...

Embodiment 3

[0054] A method for preparing an environmentally friendly high-strength plastic building formwork, characterized in that it comprises the following steps:

[0055] Step S1, dicarboxyl-modified 4-fluorophenylboronic acid methyliminodiacetate: add 4-fluorophenylboronic acid methyliminodiacetate and chloromalonic acid to an organic solvent, at 50 The reaction was stirred and reacted at ℃ for 7 hours, and then the solvent was removed by rotary evaporation to obtain dicarboxyl-modified 4-fluorophenylboronic acid methyliminodiacetate;

[0056] Step S2, preparation of polycondensate: the dicarboxy-modified 4-fluorophenylboronic acid methyliminodiacetate, 2,4-diamino-6-diallylamino-1, 3,5-triazine, polymerization inhibitor and catalyst are added in the high boiling point solvent, after stirring evenly, the reaction solution is obtained, then the reaction solution is transferred to the high-pressure reactor, and the air in the reactor is replaced with an inert gas, and then the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com