Construction method of maintainable assembly type floating equipment foundation

A technology of equipment foundation and construction method, applied in infrastructure engineering, protective devices, buildings, etc., can solve problems such as poor comfort, poor sound insulation performance, poor waterproof performance, etc., and achieve convenient drainage, sound insulation and vibration reduction capabilities Strong, good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

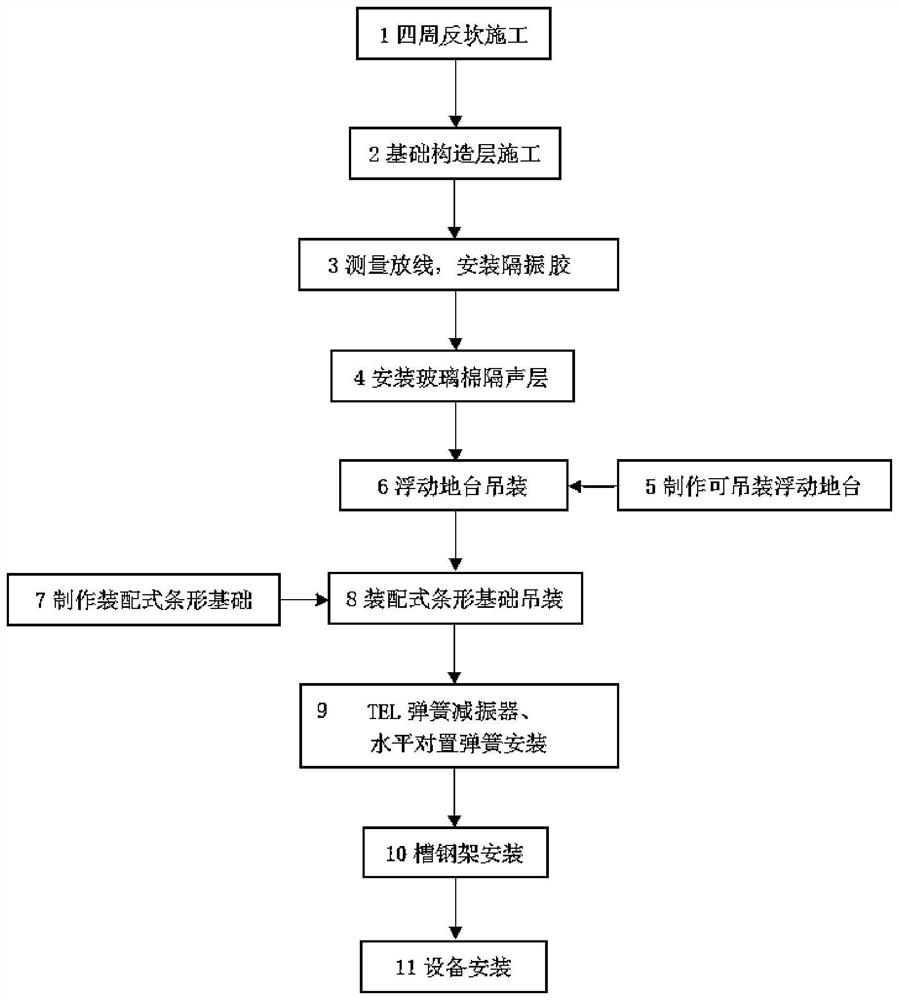

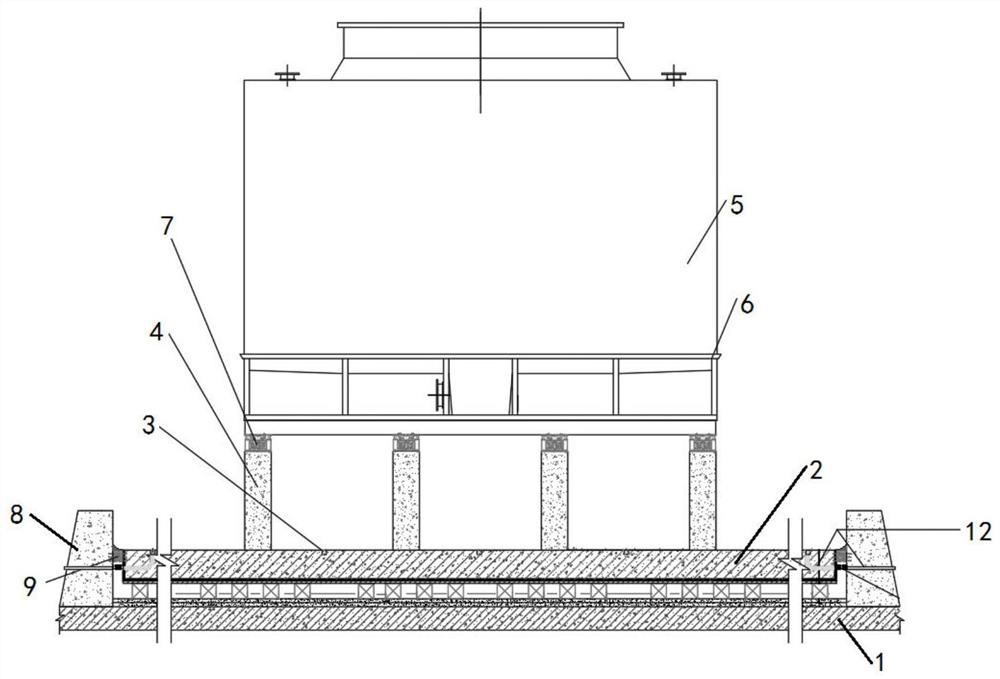

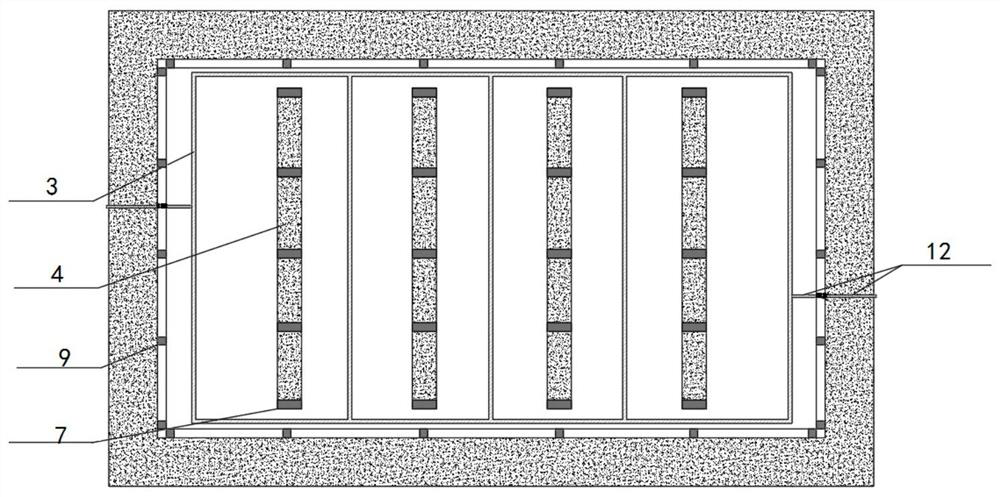

[0034] refer to Figure 1-4 , a construction method for a maintainable assembled floating equipment foundation, comprising the following steps:

[0035] S1. Anti-sill construction around: According to the design drawings, the positioning line of the anti-sill is measured to the floor, and after the verification is correct, the reinforcement is planted and the hair is chiseled; before the reinforcement is bound, the material, specification, shape, size, etc. of the reinforcement are checked and bound. When reinforcing the reinforcement, fasten the cross points of the two rows around, and fasten the cross points in the middle part alternately to ensure that the steel bars do not shift, and use finished pads to ensure the thickness of the steel bar protective layer; form reinforcement; pouring concrete and curing;

[0036] S2. Construction of foundation structure layer 1: clean the floor, brush a layer of plain cement slurry, level and slope with 1:2.5 cement mortar (thinnest 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com