Mud and sand blockage prevention and control technology suitable for water injection of loose sandstone reservoir

A technology for sandstone reservoirs and silt, which is applied in the technical field of water injection and oil recovery in oilfields, and can solve problems such as high clay mineral content, silt and sand clogging, and shortened water injection and oil recovery cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

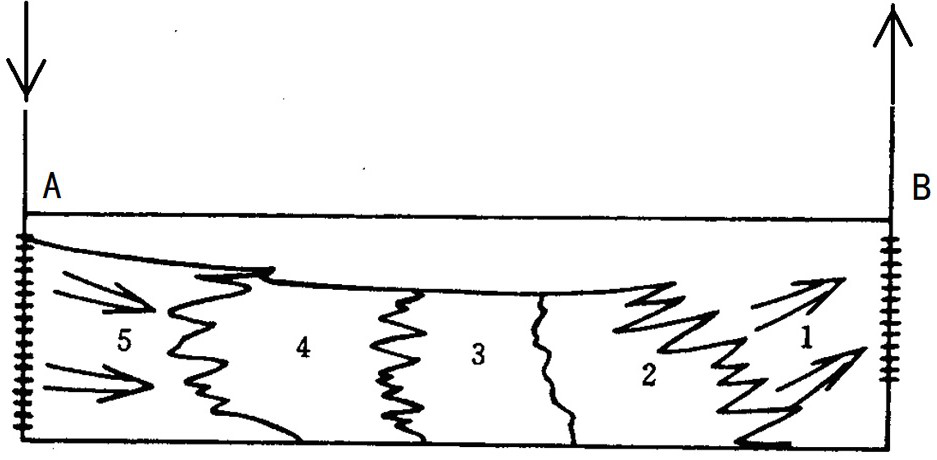

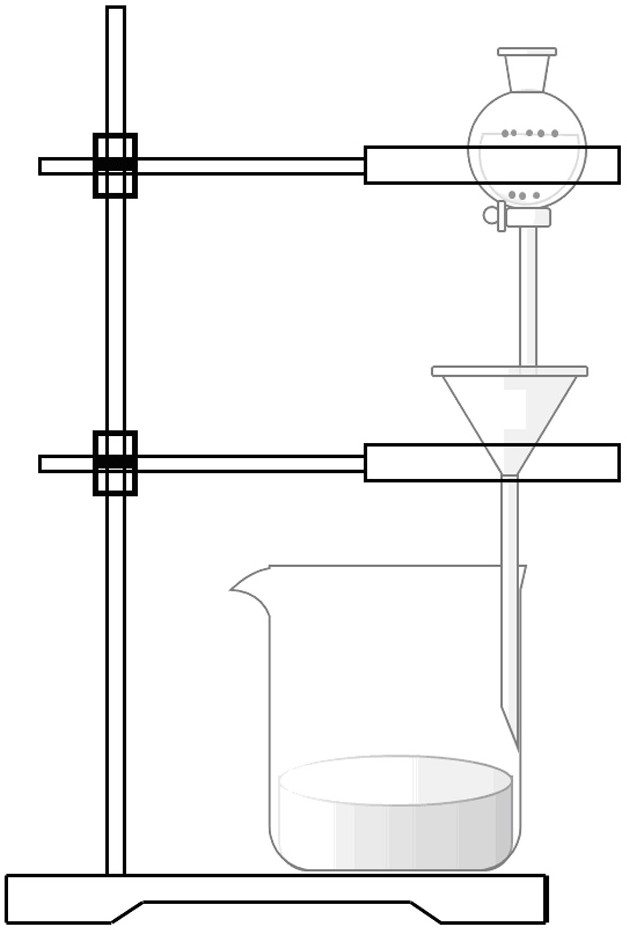

[0025] A mud-sand clogging prevention and control technology suitable for water injection development of unconsolidated sandstone reservoirs mentioned in the present invention, its technical solution is: before injecting water into the formation through the injection well, first inject a brine slug into the formation, and then inject a wetting reversal Add a slug of clay stabilizer solution, then inject a slug of clay stabilizer solution, and finally begin water injection.

[0026] The salt in the brine slug is an inorganic potassium salt, specifically industrial potassium chloride, with a concentration of 8% by mass.

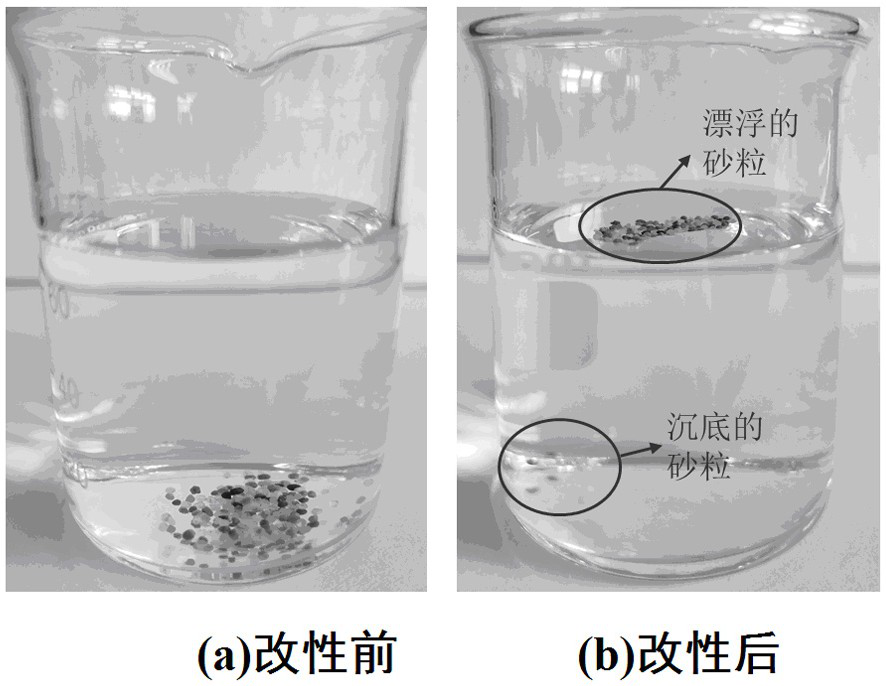

[0027] The wetting reversal agent in the wetting reversal agent solution slug is a non-ionic organic amine surfactant, specifically hexadecylamine, with a concentration of 0.4% by mass.

[0028] The clay particle anti-migration agent in the clay particle anti-migration agent solution slug is an organic cationic polymer, specifically acrylamide and (2-acrylamide...

Embodiment 2

[0055] A mud-sand clogging prevention and control technology suitable for water injection development of unconsolidated sandstone reservoirs mentioned in the present invention, its technical solution is: before injecting water into the formation through the injection well, first inject a brine slug into the formation, and then inject a wetting reversal Add a slug of clay stabilizer solution, then inject a slug of clay stabilizer solution, and finally begin water injection.

[0056] The salt in the brine slug is an organic potassium salt, specifically potassium formate, with a concentration of 6% by mass.

[0057] The wetting reversal agent in the wetting reversal agent solution slug is a cationic surfactant, specifically cetyltrimethylammonium bromide, with a concentration of 0.3% by mass.

[0058] The clay particle anti-migration agent in the clay particle anti-migration agent solution slug is an organic non-ionic polymer, specifically polyvinyldimethylamide, with a concentra...

Embodiment 3

[0072] A mud-sand clogging prevention and control technology suitable for water injection development of unconsolidated sandstone reservoirs mentioned in the present invention, its technical solution is: before injecting water into the formation through the injection well, first inject a brine slug into the formation, and then inject a wetting reversal Add a slug of clay stabilizer solution, then inject a slug of clay stabilizer solution, and finally begin water injection.

[0073] The salt in the brine slug is an organic guanidine salt, specifically guanidine hydrochloride, with a concentration of 5% by mass.

[0074] The wetting reversal agent in the wetting reversal agent solution slug is a cationic surfactant, specifically octadecyltrimethylammonium chloride, with a concentration of 0.3% by mass.

[0075] The clay particle anti-migration agent in the clay particle anti-migration agent solution slug is an organic cationic polymer, specifically acrylamide and (2-acrylamido-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com