Ceramic pump body

A ceramic pump, shaft body technology, applied in the direction of pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of reducing fluid erosion on seal rings and seal ring grooves, poor anti-cavitation performance, and cavitation. Achieve high yield and dimensional accuracy, improve mechanical strength and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

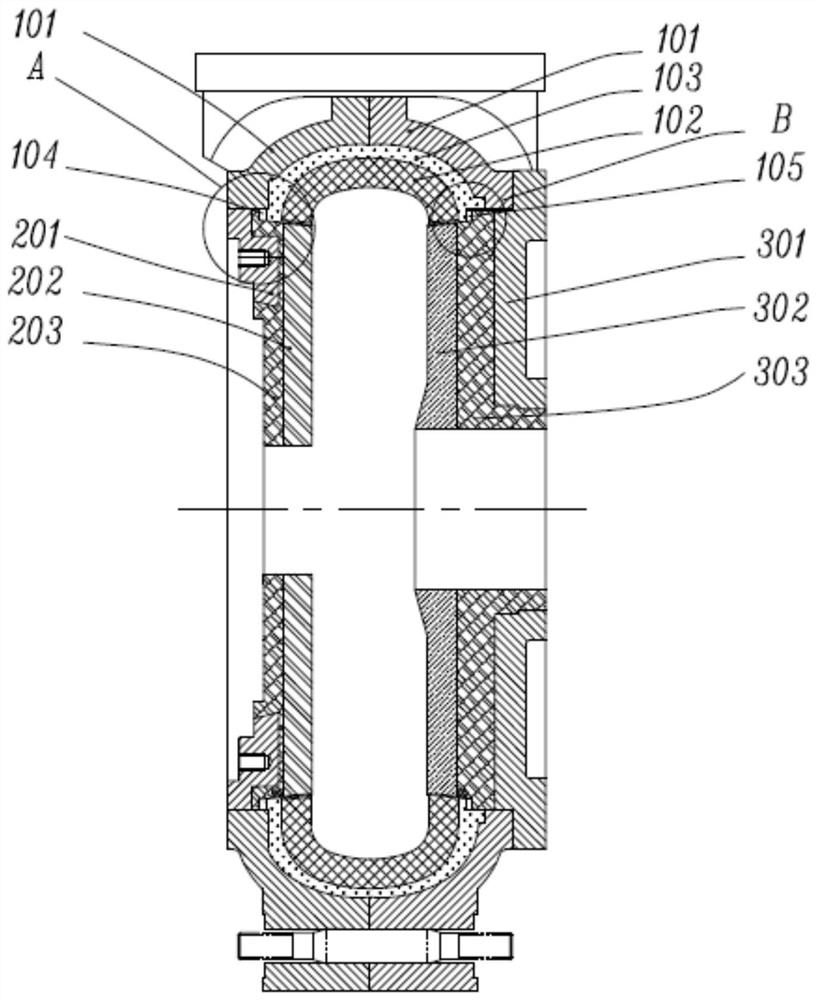

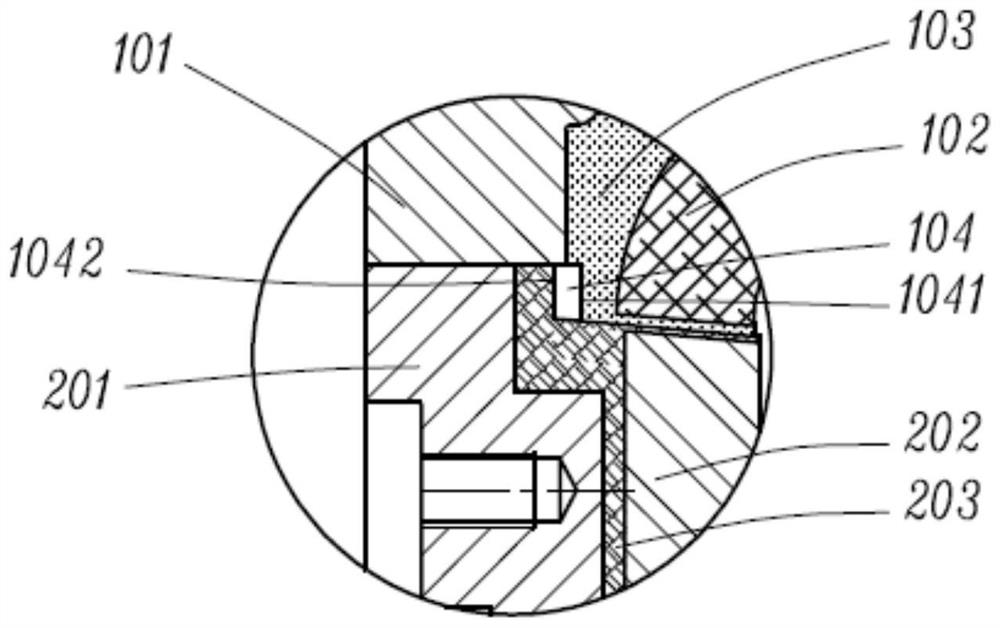

[0047] Specific embodiments of the present invention 1 refer to Figure 1-7 As shown, a ceramic pump body includes a volute and a guard plate, and the volute includes a casing 101 and a volute lining 102 . The guard plate includes a guard plate skeleton and a guard plate inner liner, and a first buffer layer 103 is arranged between the casing 101 and the volute inner liner 102 . The middle part of the volute is provided with a through hole and a tapered hole sequentially from the outside to the inside, and the through hole is connected with the tapered hole through the first axial end surface. A second buffer layer is arranged between the frame of the guard plate and the lining of the guard plate, a shaft body and a taper shaft are arranged on the guard plate in turn, and the shaft body is connected to the taper shaft through the second axial end face. The shaft fits with the through hole, and the taper shaft fits with the taper hole. An annular space for placing a seal is f...

Embodiment 2

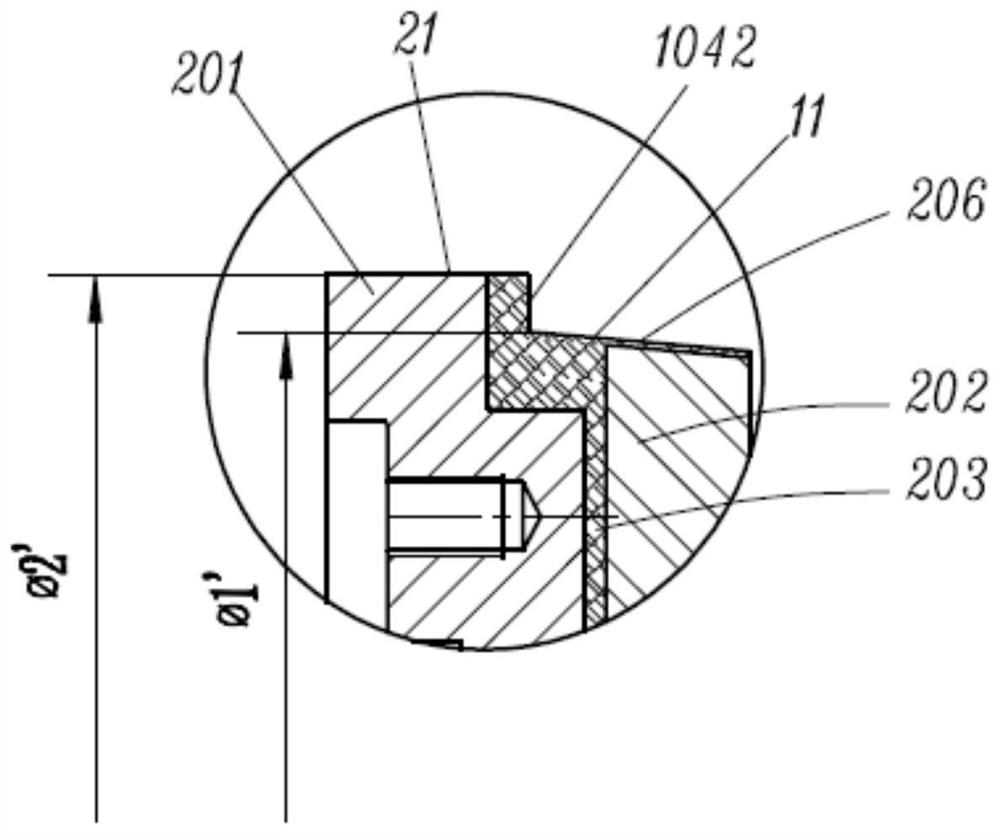

[0060] Such as Figure 8 , 9 , 10, this embodiment is roughly the same as Embodiment 1, the difference is that no front guard plate is provided, and the second axial rear end surface 1042 of the first annular space 104 is made of silicon carbide ceramic material, and the first tapered shaft The material of 11 is also silicon carbide ceramics. Obviously, the rear guard plate of this structure generally needs to be machined to meet the sealing requirements, but because the size of the rear guard plate is small and the outer circle of the machining shaft, the cost of this mechanical cutting process is relatively low, so It can still meet the requirements of some production processes.

Embodiment 3

[0062] Such as Figure 11 to Figure 14 As shown, this embodiment is substantially the same as Embodiment 2, except that the volute is provided with auxiliary through holes, and the auxiliary through holes, through holes and tapered holes are arranged in sequence. The auxiliary through hole is connected with the through hole through the first auxiliary axial end surface. An auxiliary shaft body is arranged on the guard plate, the auxiliary shaft body, the shaft body and the taper shaft are arranged in sequence, and the auxiliary shaft body is connected with the shaft body through the second auxiliary axial end surface. The inner wall of the auxiliary through hole, the outer wall of the shaft, the first auxiliary axial end surface and the second auxiliary axial end surface enclose an auxiliary annular space for placing the auxiliary seal.

[0063] In this embodiment, the auxiliary through hole is the first auxiliary through hole 50, which is arranged on the rear side of the vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com